4Unidrive SP Regen Installation Guide

www.controltechniques.com Issue Number: 2

Contents

1 Safety Information .................................6

1.1 Warnings, Cautions and Notes .............................6

1.2 Electrical safety - general warning ........................6

1.3 System design and safety of personnel ................6

1.4 Environmental limits ..............................................6

1.5 Compliance with regulations .................................6

1.6 Special note on SECURE DISABLE/ENABLE

function in regen operation ....................................6

1.7 Adjusting parameters ............................................6

2 Introduction ............................................7

2.1 Regen operation ....................................................7

2.2 Advantages of Unidrive SP operating in regen

mode .....................................................................7

2.3 Principles of operation ...........................................7

2.4 Power flow .............................................................8

2.5 Synchronisation .....................................................8

2.6 Current trimming ...................................................8

2.7 Regen system configurations ................................8

2.8 Regen drive system types .....................................9

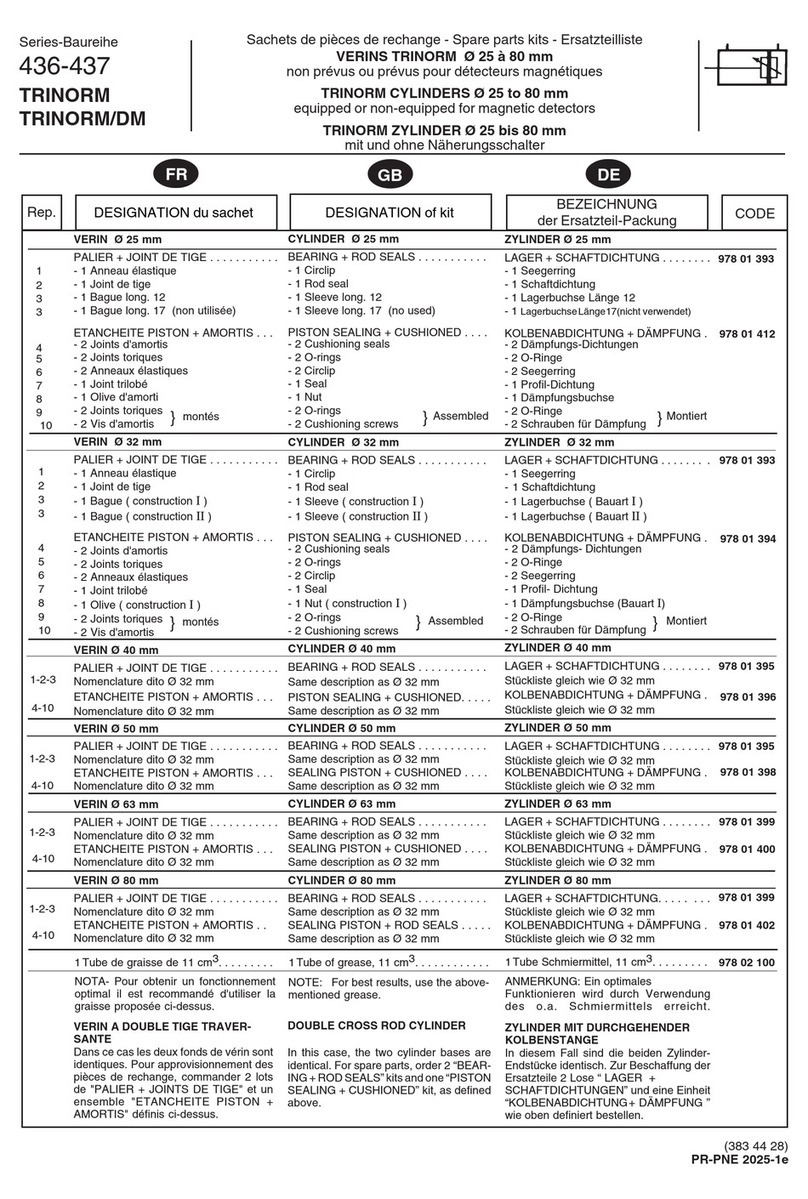

3 Product Information ............................12

3.1 Model number .....................................................12

3.2 Nameplate description ........................................12

3.3 Ratings ................................................................13

3.4 Drive features ......................................................17

3.5 Unidrive SPMC half controlled thyristor rectifier ..19

3.6 Unidrive SPMC/U technical data .........................20

3.7 Output Sharing Chokes (for motoring drives

only) ....................................................................22

3.8 Options ................................................................23

3.9 Items supplied with the drive ...............................25

3.10 Regen components .............................................25

4 System design .....................................30

4.1 Introduction .........................................................30

4.2 Power connections ..............................................30

4.3 Non standard applications ...................................40

4.4 Cable length restrictions ......................................40

4.5 Cable types and lengths ......................................42

4.6 Exceeding maximum cable length ......................42

5 Mechanical Installation .......................45

5.1 Safety information ...............................................45

5.2 Planning the installation ......................................45

5.3 Regen component dimensions ............................46

5.4 External EMC filter .............................................55

5.5 Enclosure ............................................................62

5.6 Cubicle design and drive ambient temperature ...64

6 Electrical Installation .......................... 65

6.1 Power connections ............................................. 66

6.2 AC supplies ........................................................ 74

6.3 Cable and fuse ratings ....................................... 75

6.4 EMC (Electromagnetic compatibility) ................. 77

6.5 External EMC filter ............................................. 78

6.6 Control connections ........................................... 83

7 Getting started .................................... 86

7.1 Regen parameter settings .................................. 86

7.2 Regen drive sequencing .................................... 86

7.3 Regen drive commissioning ............................... 87

7.4 Motoring drive commissioning ............................ 88

8 Optimisation ........................................ 89

8.1 Power feed-forward compensation (Pr 3.10) ..... 89

8.2 Current loop gains .............................................. 89

8.3 Voltage controller gain (Pr 3.06) ........................ 90

8.4 Power factor correction (Pr 4.08) ....................... 91

8.5 Current trimming ................................................ 91

9 Parameters .......................................... 92

9.1 Parameter ranges and variable maximums: ...... 92

9.2 Menu 0: Basic parameters ................................. 93

9.3 Menu 3: Regen sequencer ................................. 94

9.4 Menu 4: Current control ................................... 100

9.5 Menu 5: Regen control ..................................... 107

9.6 Menu 6: Clock .................................................. 111

9.7 Menu 7: Analogue I/O ...................................... 119

9.8 Menu 8: Digital I/O ........................................... 132

9.9 Menu 9: Programmable logic, motorised pot

and binary sum ................................................. 138

9.10 Menu 10: Status and trips ................................ 146

9.11 Menu 11: General drive set-up ......................... 154

9.12 Menu 12: Threshold detectors and variable

selectors ........................................................... 165

9.13 Menu 14: User PID controller ........................... 172

9.14 Menus 15, 16 and 17: Solutions Module set-up 178

9.15 Menu 18: Application menu 1 ........................... 179

9.16 Menu 19: Application menu 2 ........................... 180

9.17 Menu 20: Application menu 3 ........................... 181

9.18 Menu 22: Additional menu 0 set-up ................. 182

10 Technical data ................................... 183

10.1 Drive ................................................................. 183

10.2 Supply requirements ........................................ 191

10.3 Protection ......................................................... 192

10.4 Component data ............................................... 196

10.5 Optional external EMC filters ........................... 199

11 Component sizing ............................. 203

11.1 Sizing of MCB for switching frequency filter ..... 203

11.2 Resistor sizing for multiple drive systems ........ 204

11.3 Thermal / magnetic overload protection for soft

start circuit ........................................................ 204