5

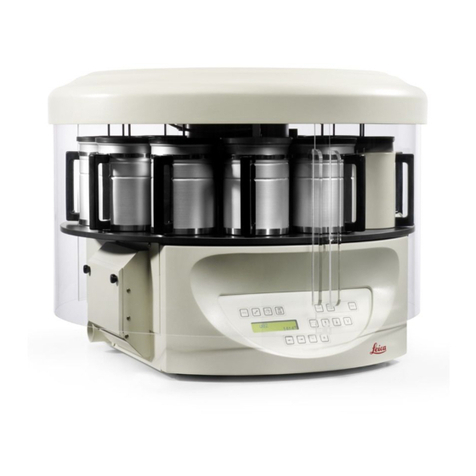

ASP6025 Tissue Processor

Table of Contents

4.7 Touchscreen functions ........................................................................................................................................... 61

4.8 Switching o the instrument correctly .................................................................................................................. 65

5. Operation ............................................................................................................................... 66

5.1 System conguration - conguring the instrument parameters ........................................................................... 66

5.1.1 The Installation menu............................................................................................................................................ 66

5.1.2 System settings ..................................................................................................................................................... 69

5.1.3 User proles .......................................................................................................................................................... 78

5.1.4 The System monitor menu .................................................................................................................................... 80

5.1.5 The Service functions menu................................................................................................................................... 82

5.1.6 System status ........................................................................................................................................................ 84

5.1.7 The Run log ........................................................................................................................................................... 87

5.1.8 The Eternal error log.............................................................................................................................................. 89

5.1.9 Saving or loading data........................................................................................................................................... 90

5.1.10 The Smart Screen .................................................................................................................................................. 95

5.2 Reagents ............................................................................................................................................................... 98

5.2.1 Editing the reagent list.......................................................................................................................................... 98

5.2.2 The RMS system - adjusting warning threshold values........................................................................................ 100

5.2.3 The reagent status............................................................................................................................................... 104

5.2.4 Conguring the stations...................................................................................................................................... 106

5.2.5 The Reagent groups menu................................................................................................................................... 107

5.2.6 Ethanol rotation .................................................................................................................................................. 108

5.2.7 Adjusting the threshold value for ethanol rotation.............................................................................................. 111

5.2.8 Replacing xylene ................................................................................................................................................. 112

5.3 Inltration programs........................................................................................................................................... 113

5.3.1 Display of the program list................................................................................................................................... 113

5.3.2 Adding and modifying programs......................................................................................................................... 114

5.4 Reagent handling................................................................................................................................................ 117

5.4.1 Filling/draining reagents..................................................................................................................................... 117

5.4.2 Relling paran ................................................................................................................................................. 123

5.4.3 Draining a paran bath ...................................................................................................................................... 125

5.5 Running programs............................................................................................................................................... 127

5.5.1 User-dened programs ....................................................................................................................................... 127

5.5.2 Favorites.............................................................................................................................................................. 128

5.5.3 Dening Favorite programs ................................................................................................................................. 129

5.5.4 Starting a program.............................................................................................................................................. 132

5.5.5 Ending a program................................................................................................................................................ 136

5.6 Permanently installed inltration programs........................................................................................................ 137