Page - 4

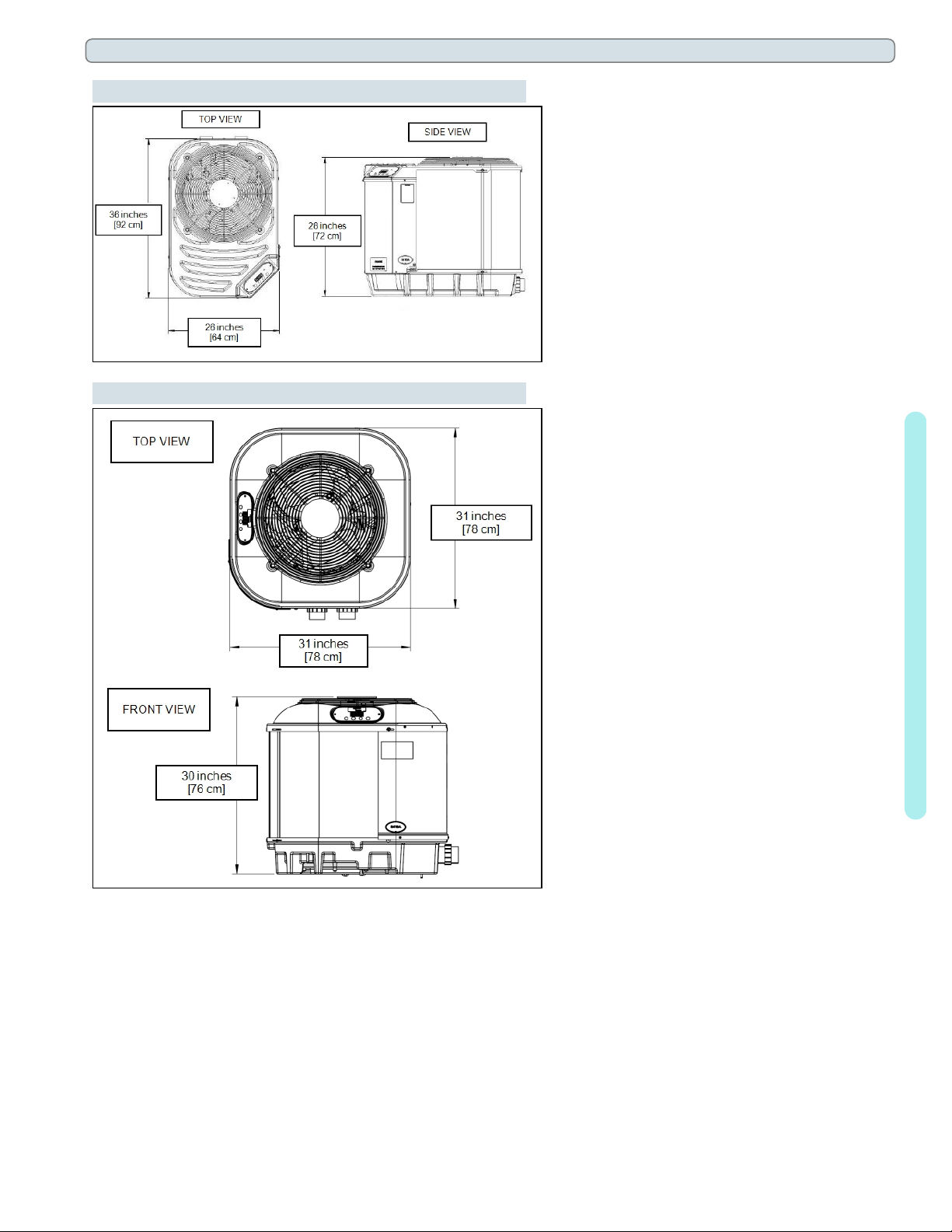

1.1 Positioning Equipment

NOTICE

Failure to heed the following may result in damage to equipment.

lDo not install equipment inside of a building.

Outdoor Use Only

Do not install equipment inside of a room or building.

lHeat Pumps require unobstructed airflow for proper operation. Heat Pumps should never be installed indoors or in

a location where airflow is restricted.

lIf an indoor installation is being considered, the installer and dealer are strongly urged to contact the Leisure

Temp Application Department, or a local Professional Engineer prior to proceeding.

lSee "Clearances" on the next page.

Controlling Irrigation and Rainwater Runoff

lIrrigation water may damage heat pump components. Direct irrigation water away from the heat pump.

lThe heat pump will withstand normal rainfall. Do not allow a roof slope to direct rainwater onto the heat pump.

Have a gutter installed on the roof edge to direct this water away from the heat pump. Or install the heat pump in

another location.

Planning for Condensation

The heat pump can produce a large amount of condensation. The amount of water depends on air temperature

and humidity.

lInstall the heat pump with enough height to allow for water drainage.

lPlan for water drainage as needed.

Mounting Pad Requirements

lThe heat pump's base must be installed on a flat and level surface that completely supports the entire base.

lBuild the heat pump pad out of concrete or other code-approved material.

lConfirm the pad can support the weight of the heat pump. See "Weights" on page66.

lElevate the pad enough to allow for drainage.

lMake sure the pad is flat and level.

lHave the pad support the entire heat pump base in all directions.

lDo not install the heat pump on soil or grass.

lDo not allow the heat pump base to touch the building's foundation.

lDo not place the heat pump directly on a concrete floor. This can cause noise to be transmitted to an occupied

space. If necessary install vibration dampers between the heat pump base and floor.

lEquipment pad must meet all requirements of authorities having code-related jurisdiction.

Anchoring to Pad

lFollow all applicable local, state, and national requirements regarding wind load anchoring.

lThe shipping brackets used to secure the heat pump to the pallet are approved mounting (hurricane) brackets.

They should be used to anchor the heat pump to the pad.

lIf needed, contact Leisure Temp to obtain anchoring kit information. Please have the heat pump model number

and serial number when requesting support. See "Identifying Model Specifications" on page65.

1 - Installation