SAFETY PRECAUTIONS

WARNING

1) Do not spray paints or other inflammable

fluids indoors which have a flash point

below 21 degree C, 70 degree F. Keep spray

area well ventilated. Before spraying, turn off

all pilot lights and open flames.

2) Wear a respirator which is approved for the

product being sprayed.

3) Do not use halogenated hydrocarbon

solvents in this system; it contains alu-

minium parts and may explode. Cleaning

agents, coatings, paints, and adhesives may

contain halogenated hydrocarbon solvents.

Don't take chances, consult your material

supplier to be sure. (ex: methylene chloride

and 1,1,1 - Trichlorethane)

4) Caution: When a flammable liquid is sprayed

there may be danger of fire or explosion

especially in a closed area.

5) Caution: Arcing parts. Keep the compres-

sor at least 20 feet away from explosive

vapours.

6) Caution: Static electricity can be developed

by spraying. Ground unit and object to be

sprayed. On electric units, unit power cord

must be connected to a grounded outlet. Use

only three wire extension cords. Static

explosion can occur with ungrounded unit.

7) Always follow safety precautions and

warnings printed on paint container.

8) Do not pull on hoses to move equipment,

DO NOT kink or bend the hose sharply.

9) Keep children or anyone not familiar with air

spray systems away from equipment and

work area.

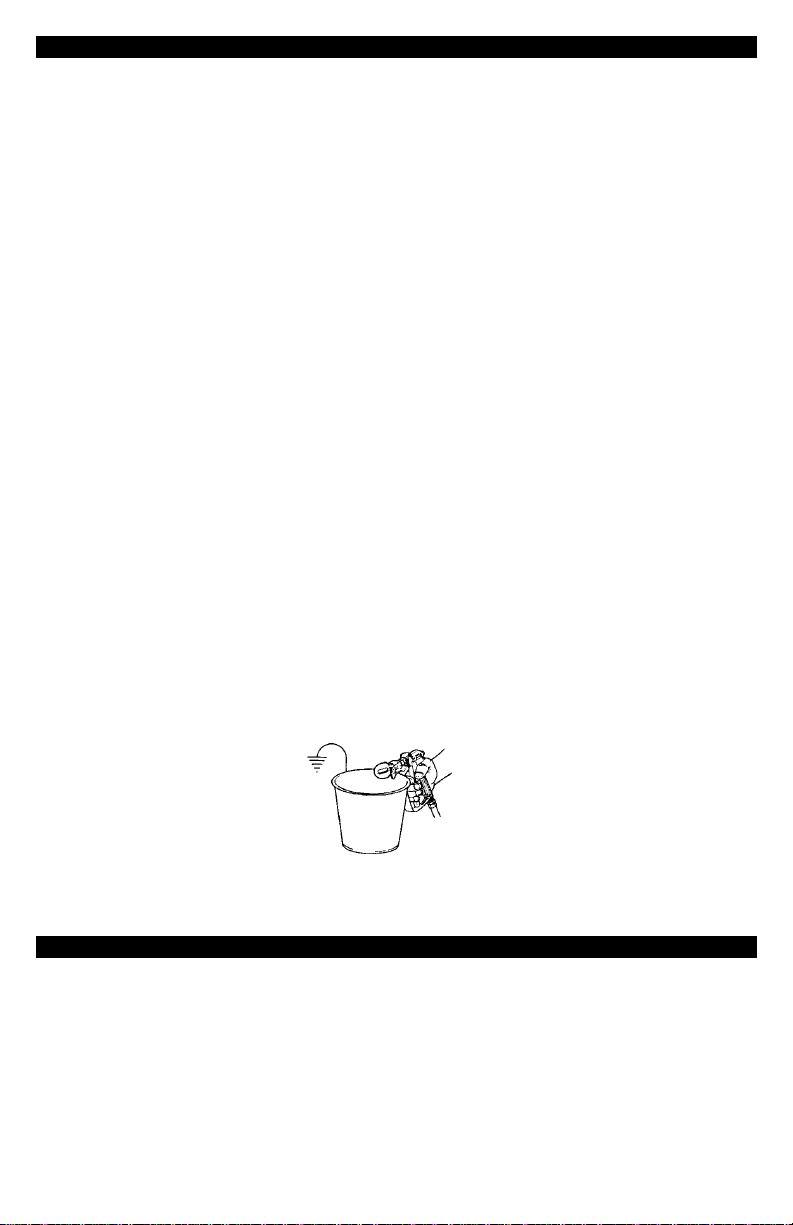

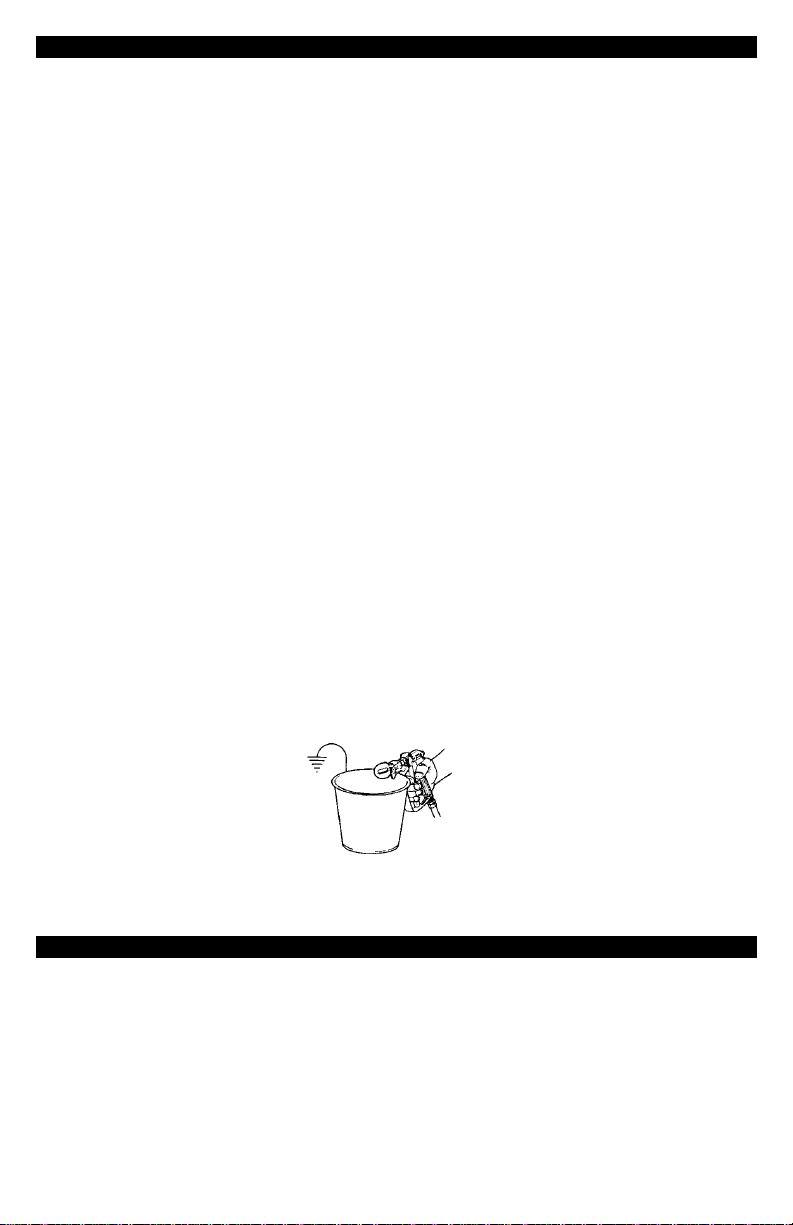

10) Conductive metal containers

must be used when flushing

flammable fluids through the

system. Always flush at low

pressure with spray tip removed.

A metal part of the spray gun

must be held firmly against the

grounded metal pail when

flushing or relieving pressure

from the gun.

ATTENTION

1) Ne jamais pulvériser à l’interieur un produit

inflammable qui a un point éclair inférieur à 21

degrés C,70 degrés F. L’endroit où vous peinturez

doit toujours être bien aéré. Avant de pulvériser

s’assurer qu’il n’y a aucune flamme ou pilot (veilleuse)

de fournaise en marche dans l’appartement.

2) Servez-vous d’un masque respiratoire qui est

certifié pour le produit que vous pulvérisez.

3) Ne pas utiliser de solvants contenant des

hydrocarbures halogénés avec ce matériel. Il

contient des particules d'aluminium et peut exploser.

Les agents de nettoyage, enduits, peintures et,

adhésifs, peuvent contenir des solvants contenant

des hydrocarbures halogénés. Soyez prudents;

consultez votre fournisseur pour les informations

nécessaires. (ex: méthylène chloride and 1,1,1 -

Trichloréthane)

4) Attention: La pulvérisaton d'un liquide inflammable

peut entraîner un risque d'incendie ou

d'explosion, surtout dans les espaces fermés.

5) Attention: Étincelles électriques. Ne pas placer la

compresseur à moins de 6 mètres des vapeurs

explosives.

6) Attention: La pression du produit que l’on pulvérise

peut produire une charge électrostatique. Mettre le

matériel et l'objet à pulvériser à la terre. Sur les

modèles électriques, le cordon électrique doit être

attaché à une prise de courrant reliée à terre. Le

cordon de rallonge doit être à 3 fils. Des décharges

d'électricité statique peuvent se produire si le matériel

n'est pas mis à la terre.

7) Toujours prendre les précautions nécessaires et

observer toutes les consignes de sécurité figurant sur

le pot de peinture.

8) Il ne faut jamais essayer de déplacer l'appareil en

tirant sur le boyau. Il faut aussi éviter tout

tortillement du boyau.

9) Les enfants et le personnes n'ayant

aucune expérience avec ce genre de

pulvérisateur doivent êtres gardés à l'écart de

l'appareil et du chantier de travail.

10) Quand on décharge des liquides

inflammables il faut utiliser des pots

conducteurs en métal. Quand on relâche la

pression avec le pistolet, une partie métallique du

pistolet doit être en contact avec le pot en métal muni

de mise à la terre.

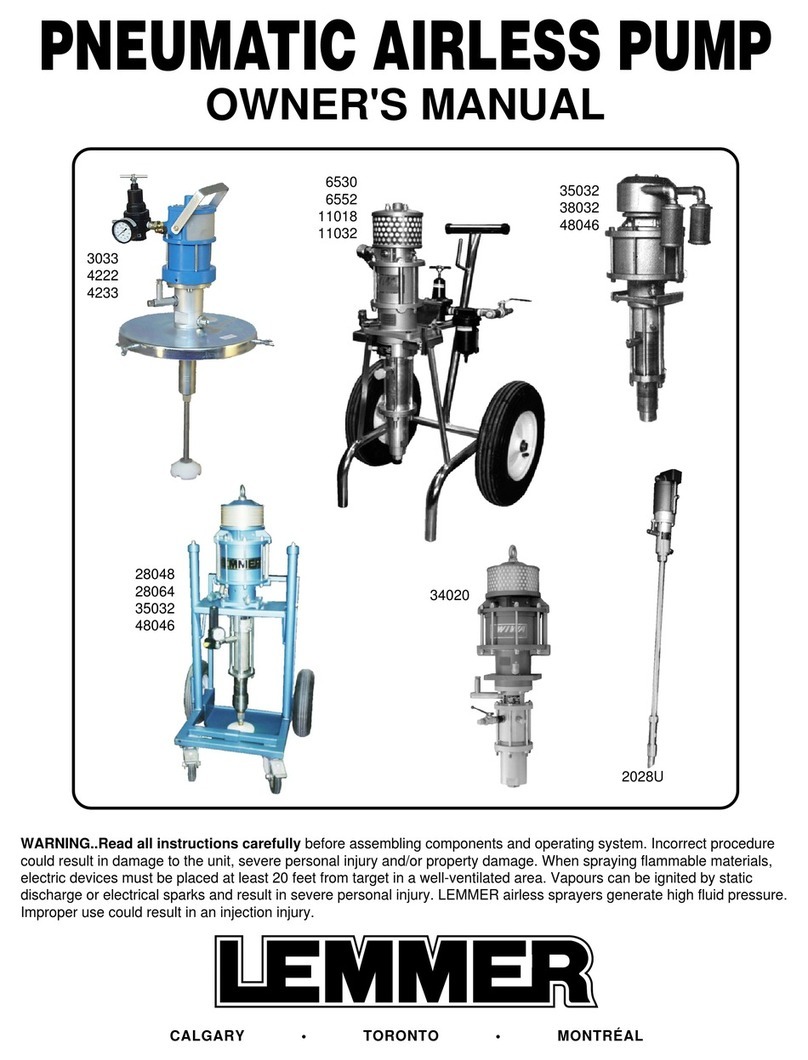

INTRODUCTION

INTRODUCTION

We appreciate your decision to purchase a

Lemmer professional pump system. If

maintained as outlined in this manual, you

will have many years of dependable service.

This transfer pump is designed for demand-

ing industrial applications.

This new pump combines high quality with a

compact design and ease of maintenance.

MPORTANT

To ensure your transfer pump reaches you in first

class condition, protective flush solvents have

been used. Flush thoroughly with compatible

solvent before use.

This pump may be used with most coatings and

rust inhibiting products, but it is not designed for

use with highly corrosive or highly abrasive

materials.