Description

2 Lenord, Bauer & Co. GmbH DS22-6505 (2014-07)

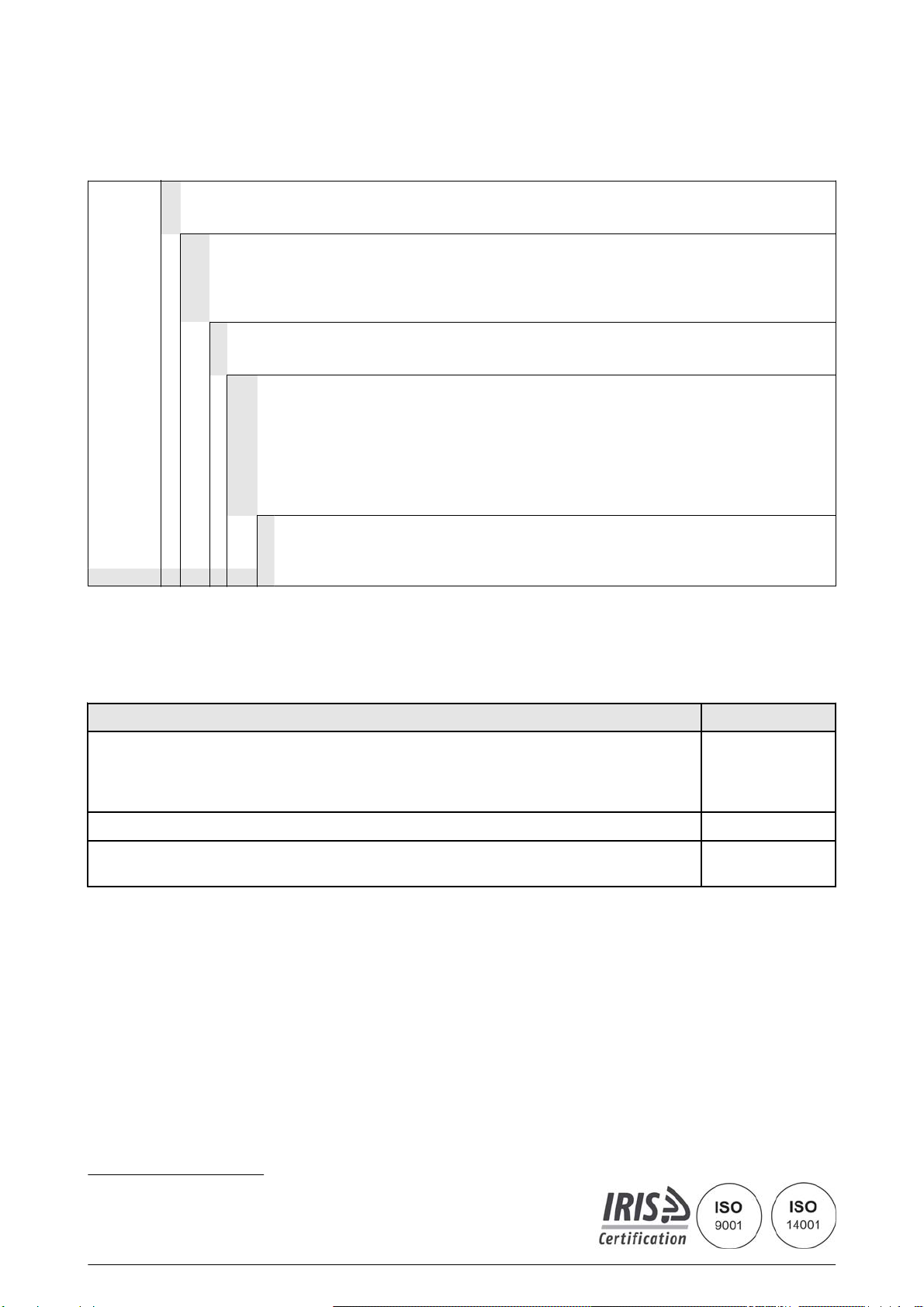

System solution

The PowerDRIVE-System consists of three basic compo-

nents: up to 5 compact, fully automated positioning drives

PowerDRIVE, the intelligent decentral communication unit

PowerDRIVE-Box and the hybrid cables PowerDRIVE-

Connect suitable for use in drag chains.

PowerDRIVE-Connect

PowerDRIVE-Box

PowerDRIVE

(5x)

The intelligent PowerDRIVE-Box simplifies commissioning

and allows an efficient integration of the PowerDRIVES in-

to the control of complex production plants. Various field

bus modules are available for the communication with the

central control system.

The PowerDRIVE-Box takes care of the entire power man-

agement for the positioning drives and significantly re-

duces the connection work. The supply of motor power,

supply of logic power and the internal CAN bus communi-

cation between the positioning drives and the Power-

DRIVE-Box are undertaken via the hybrid cable Power-

DRIVE-Connect. Instead of the usual two separate cables

for field bus communication and a third cable to supply

power to the positioning drives, the connection is reduced

to

ONE

hybrid cable suitable for use in drag chains; the lo-

gistics effort for the always identical PowerDRIVEs is mini-

mised. In the maximum configuration with 5 positioning

drives connected, the number of cables can typically be re-

ducedfrom15to5.

The automatic configuration of the PowerDRIVEs after

connection to the PowerDRIVE-BOX and the check on the

system parameters make commissioning straightforward

and quick, even without the central control system connec-

ted.

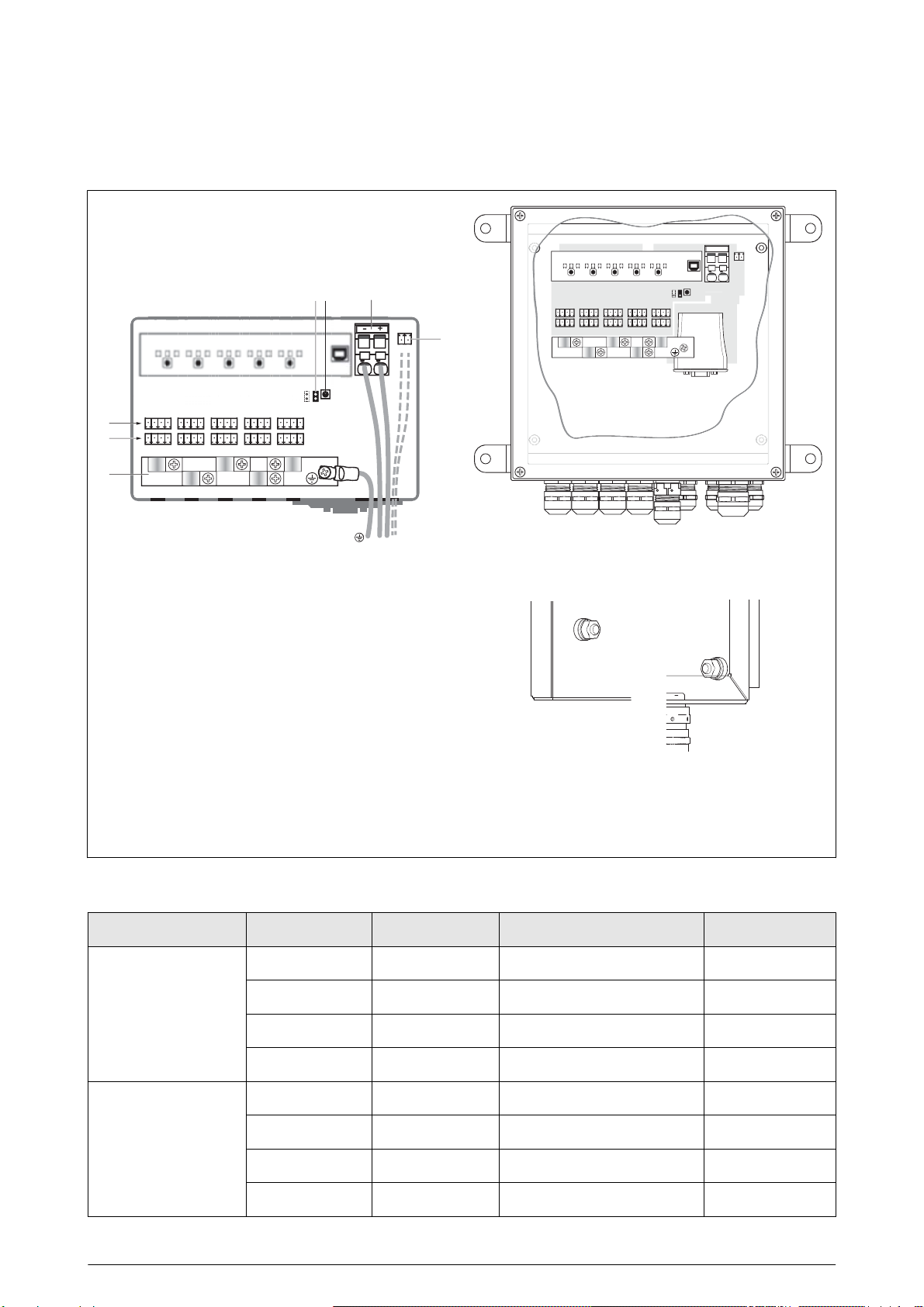

Construction of the PowerDRIVE-Box

GEL 6505A The compact housing of the PowerDRIVE-

Box made of cast aluminium is suitable for

mounting on top hat rails. For testing and

commissioning of each positioning drive,

there are state LEDs and push-buttons on the

front panel.

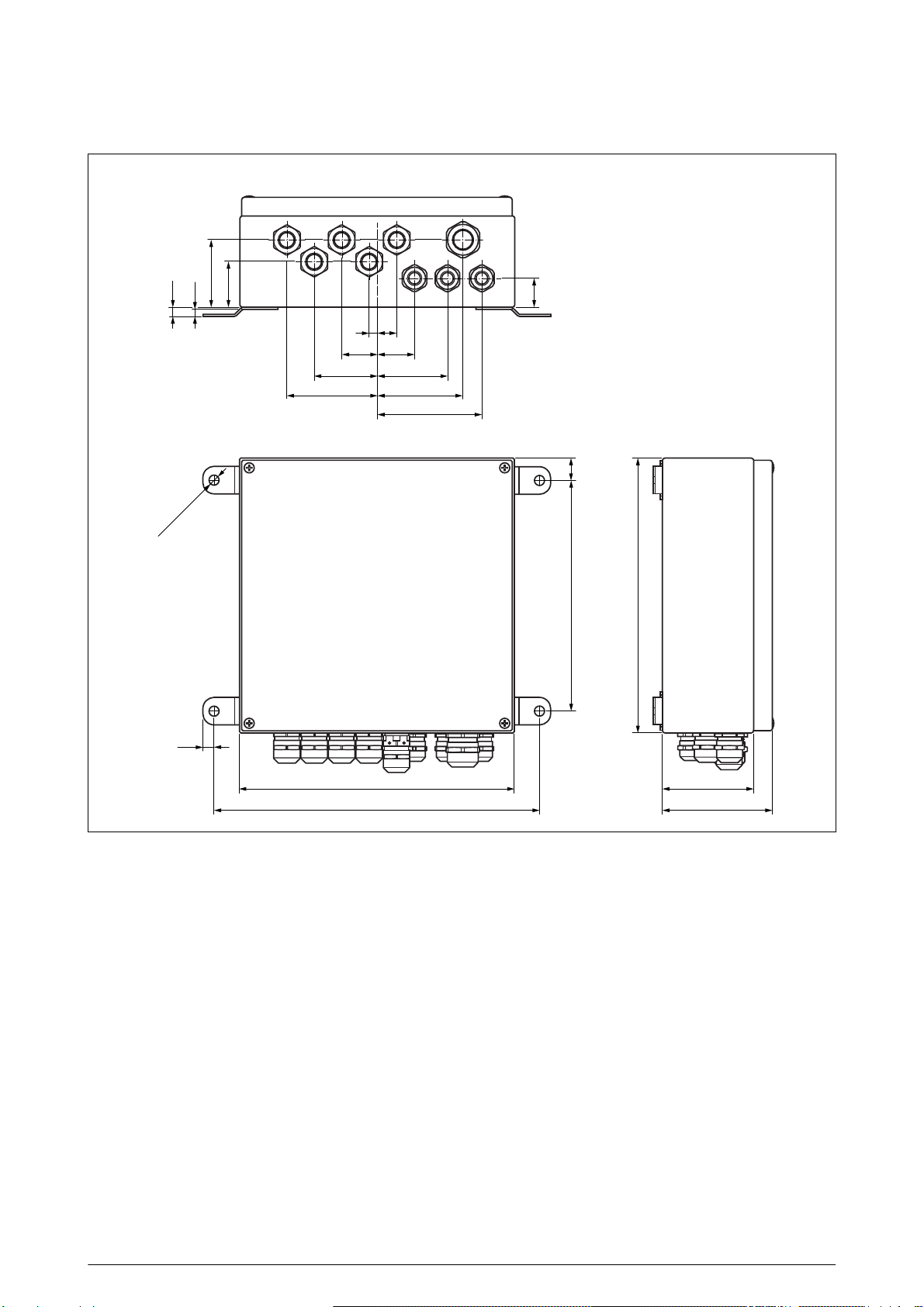

GEL 6505B The closed housing of stainless steel met

through the cable glands and blanking plugs

the protection class IP 69K. All indication and

connection elements are located inside.

For each positioning drive 3 state LEDs indicate the state

of the power supply and the communication. In case of a

malfunction or during an inspection, the drive voltage and

communication can be switched on or off using push-but-

tons under the LEDs. It is also possible to acknowledge er-

rors and perform a manual reset with the aid of the push-

buttons.

Via a USB interface, the device can be connected to a PC.

Using a terminal program, important parameters can be

read and set. Also, the firmware of the box can be updated

with the aid of a connected PC.

The pluggable fieldbus interface is supplied pre-assembled

as per the type code.

The hybrid cables for the positioning drives are connected

directly to the easily accessible and coded strips using

spring-cage terminals. The hybrid cables are earthed via

an earth rail.

For safe operation, the box provides integrated electronic

fuses. The PowerDRIVE-Box is earthed via an earth cable

and the additional earthing via the top-hat rail or mounting

brackets.

Power is supplied to the PowerDRIVE-Box and positioning

drives either via a common connection or via two separate

connections. Using separate supply, the power of the

drives can be switched off, for example during an “emer-

gency stop”, without interrupting the bus communication. In

this way state monitoring is ensured.

Integrated power management

The maximum power consumption can be programmed via

power management.

It is recommended to use a 24 V DC / 40 A voltage-stabi-

lised power supply that is preferably to be mounted beside

the PowerDRIVE-Box. The supply of power to the motors

and logic for the positioning drives is separate. For require-

ments in accordance with the new Machinery Directive, the

power for the motors can be switched via certified safety

relays in the plant. Nevertheless, continuous state monitor-

ing can be ensured, as the communication via the field bus

is not affected. In this way the drive can be safely shut

down.

PowerDRIVE-Connect

The hybrid cable PowerDRIVE-Connect is designed for

flexible application in drag chains and reaches a permissi-

ble dynamic bending radius of ten times the cable diameter

inatemperaturerangeof-40°Cto+80°C.Thediameter

of the cable is 9.5 mm. The hybrid cable is screened under

the PUR outer sheath. The internal communication cores

are fully insulated and multiply screened.

The positioning drive is available with hybrid cable and

connector. PowerDRIVE and PowerDRIVE-Box can be

quickly and easily connected with pre-assembled field at-

tachable hybrid connection cables .

The M23 quick-acting coupling of the plug connection per-

mits a rapid connection and disconnection of the devices.

In this manner, the positioning drive can be safely isolated

from the power supply within seconds for maintenance and

service work.