4

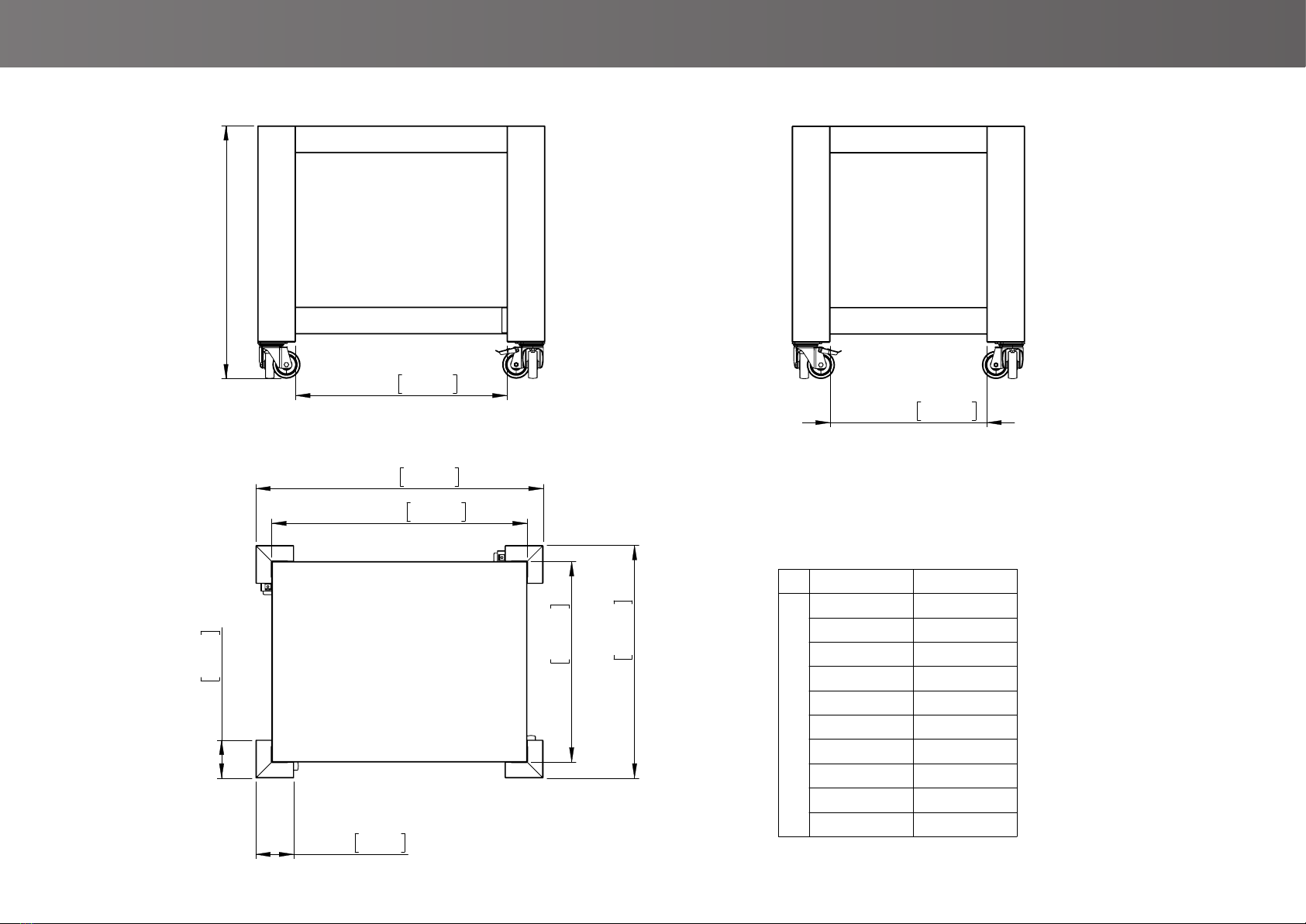

Fig.2.

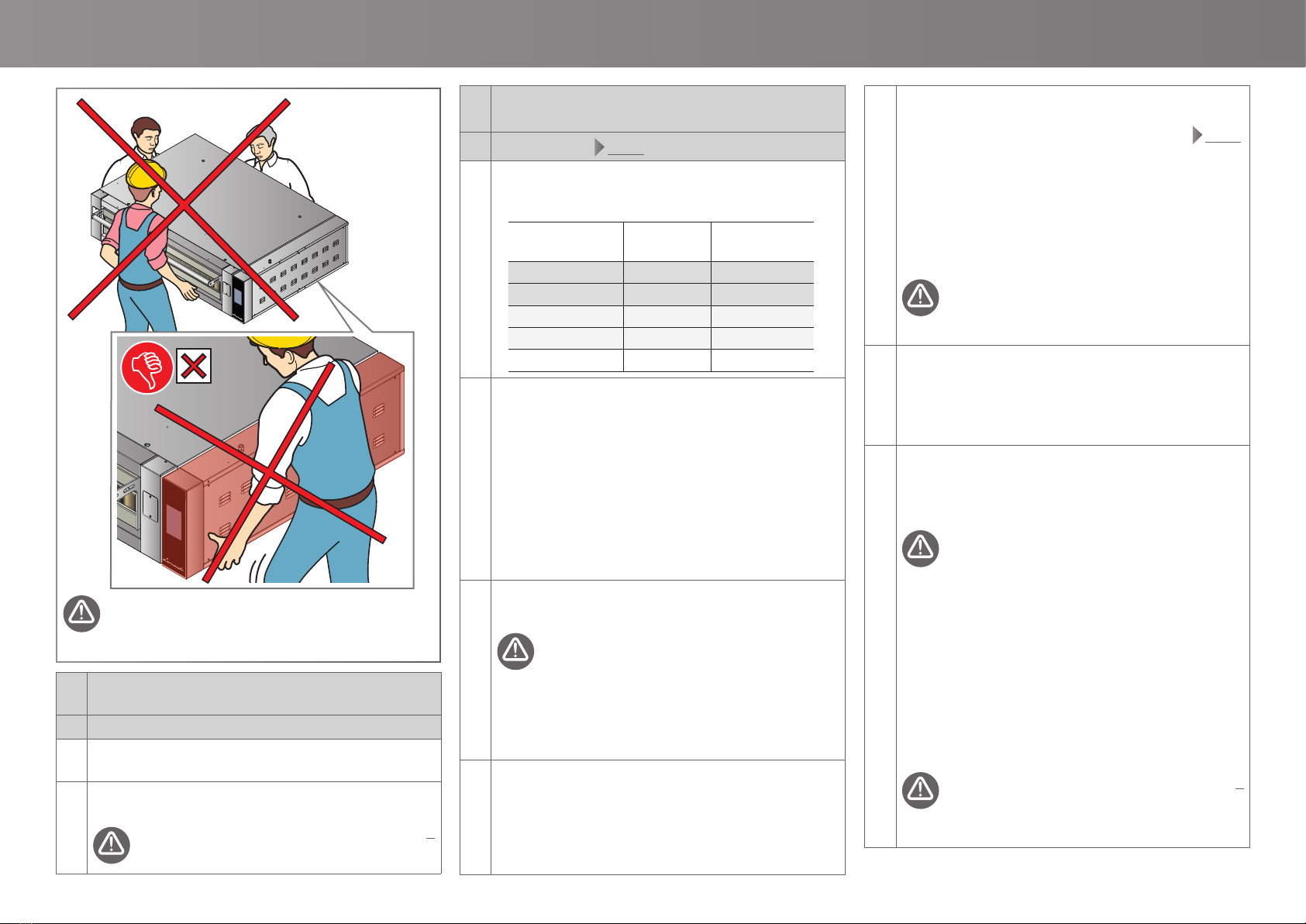

Checks before purchasing

C

Survey the installation room to make sure it is ade-

quate.

√Make sure that Fig.3.

•the oor of the installation room is reproof, per-

fectly level and capable of withstanding the weight

of the appliance;

Model refractory

surface

metal sheet

deck

LN2T/1TS - h. 18 207 kg - 456 lb 193

kg - 425 lb

LN2T/1TSH - h. 25 222

kg - 489 lb 208

kg - 458 lb

LN3T/1TS - h. 18 247

kg - 544 lb 226

kg - 498 lb

LN3T/1TSH - h. 25 262

kg - 577 lb 241

kg - 531 lb

LN650/1TS 387

kg - 853 lb 347

kg - 765 lb

•the installation room:

•is dedicated and suitable to cooking food;

•has adequate air ventilation;

•contains no flammable or explosive elements;

•complies with the current regulations on health

and safety and systems in the workplace;

•is protected from the weather;

•has a maximum temperature of between +5°C (41°F)

and +35°C (95°F);

•has a maximum humidity of 70%.

•the appliance passes through the doorways easily.

When choosing the positioning room, take into

account that the appliance must be easy to

move for any extraordinary maintenance: be

careful since any brickwork after installation (e.g.: wall

construction, door replacement with narrower ones,

renovations, etc.) do not hamper movements.

•there are NO other sources of heat (i.e. grills, fryers,

etc.), highly flammable substances or fuels (i.e. gaso-

line, petrol, bottles of alcohol, etc...) in the vicinity of

the appliance.

•It is possible to maintain the following minimum dis-

tances between the oven and the walls, other appli-

ances, objects and combustible materials Fig.4.:

•left side: 50 mm [1.97 in.]

•right side: 500 mm [19.7 in.](to allow easy access

to the electrical system; if this is not possible, when

required, the oven shall have to be moved from its

housing),

•back: 250 mm [9.84 in.]

•top: 1000 mm [39.37 in.].

It is vital to comply with the minimum safety dis-

tances that must be increased in the presence of

objects in materials sensitive to heat;

•there is adequate ventilation according to the reg-

ulations in force in the country of installation. In its ab-

sence, a ø 14 cm [Ø5.51 in.]air intake communicating

with the outside or with a ventilated room (e.g. ware-

house, attic, garage, basement) is mandatory;

•there is an evacuation ue for the exclusive use of

the equipment, with a minimum diameter of 150 mm

[Ø5.91 in.] and that complies with the regulations in

force.

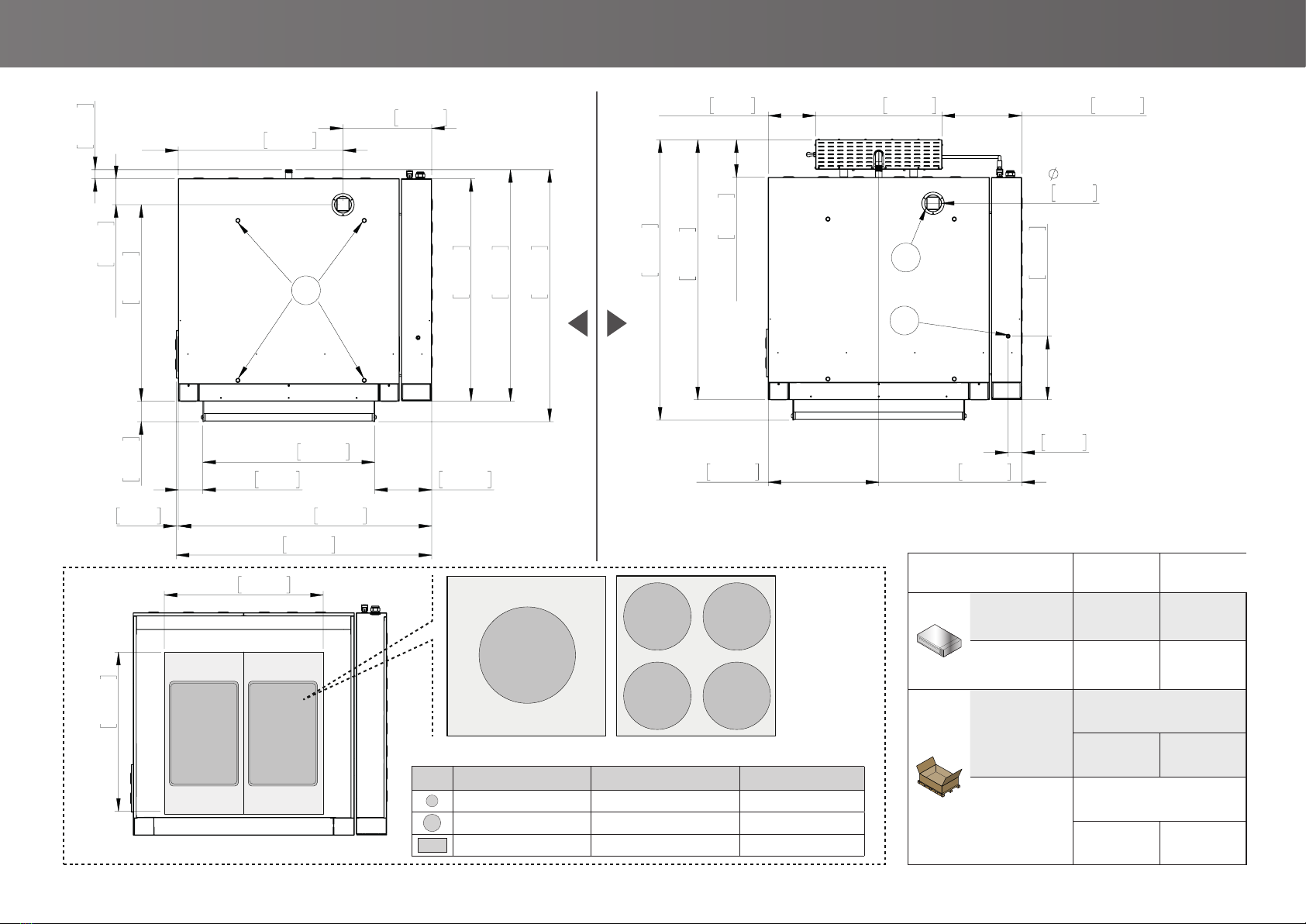

The oven is equipped with an adjustable exhaust

in the upper part to evacuate the steam coming

from the cooking chamber. This steam, together

with the one from the door during the work phases, must

be conveyed outside in one of the following ways:

•through a hood supplied by the Manufacturer

that ensures perfect compatibility with the oven. For

correct assembly and fixing to the oven, consult the

sheet attached to it.

•through an adequate extraction system supplied by the

user: in this case a draught switch must be installed be-

tween the extractor and the oven chimney (the extrac-

tor and switch are not supplied by the Manufacturer).

In the “Technical data” section from page 6

you can find the indication of the position of the

evacuation flue.

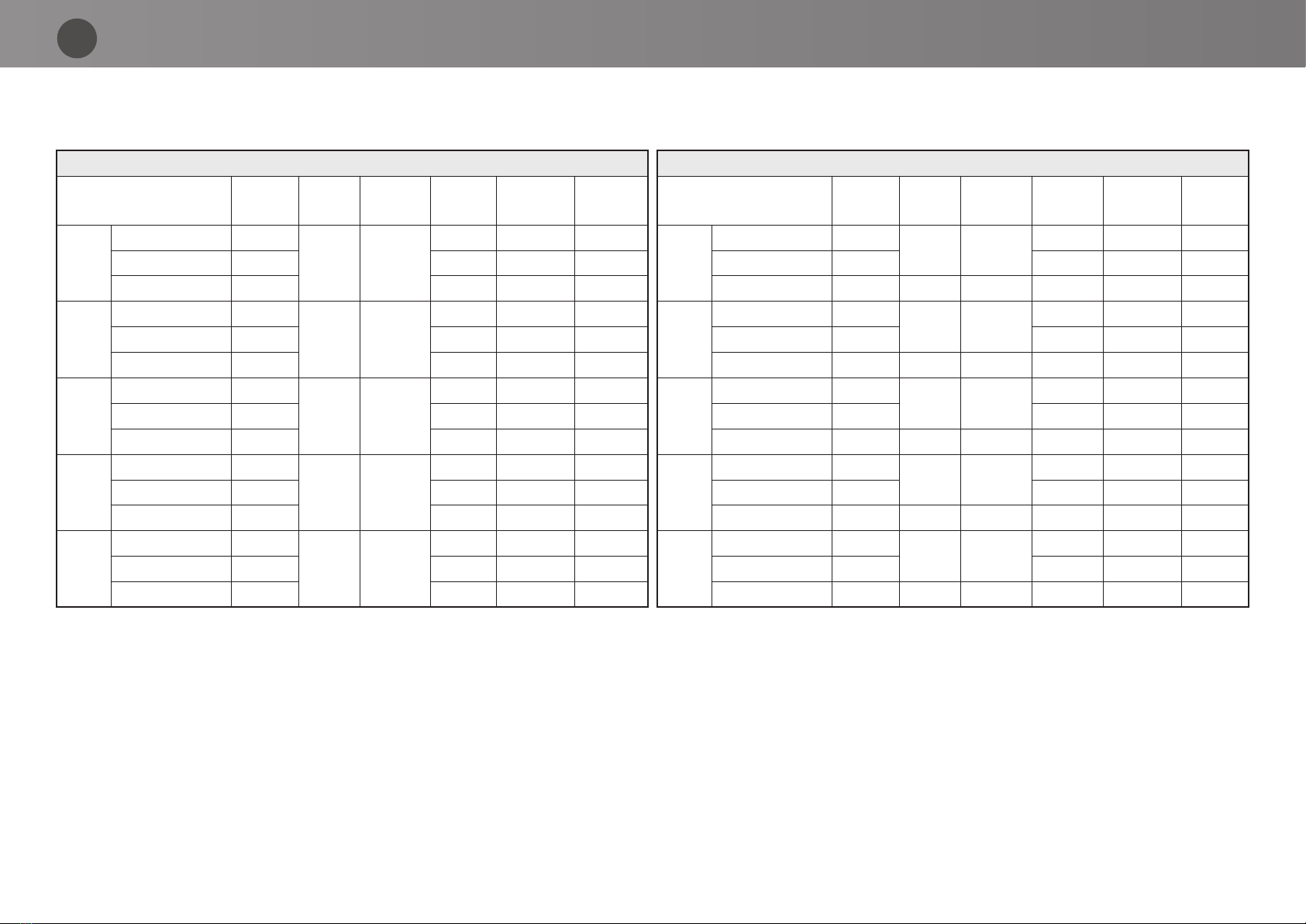

B Check the dimensions of the selected oven and

accessories

åcheck that the dimensions of the selected oven are

suitable to the available space in the installation room.

•check that the cooking chamber capacity is adequate

to the owner's needs.

The “Technical data” section from page 6

contains the weights and dimensions of the

cooking chamber.

Do not use this part as a lifting point for any re-

ason, this could damage the equipment.