Ed. 0121 - 70702553 REV01 Leonardo Oven - Quick Guide 7

Предупреждения по безопасности

Advertencias de seguridad

Sicherheitshinweise

Consignes de sécuritéSafety instructions

Installer warnings

EN

•Read this guide carefully before installing the

appliance, and keep it with care in an accessible

place for any future consultation by the various

operators.

•Moreover, the manual must always accompany

the product through its life, even in case of transfer.

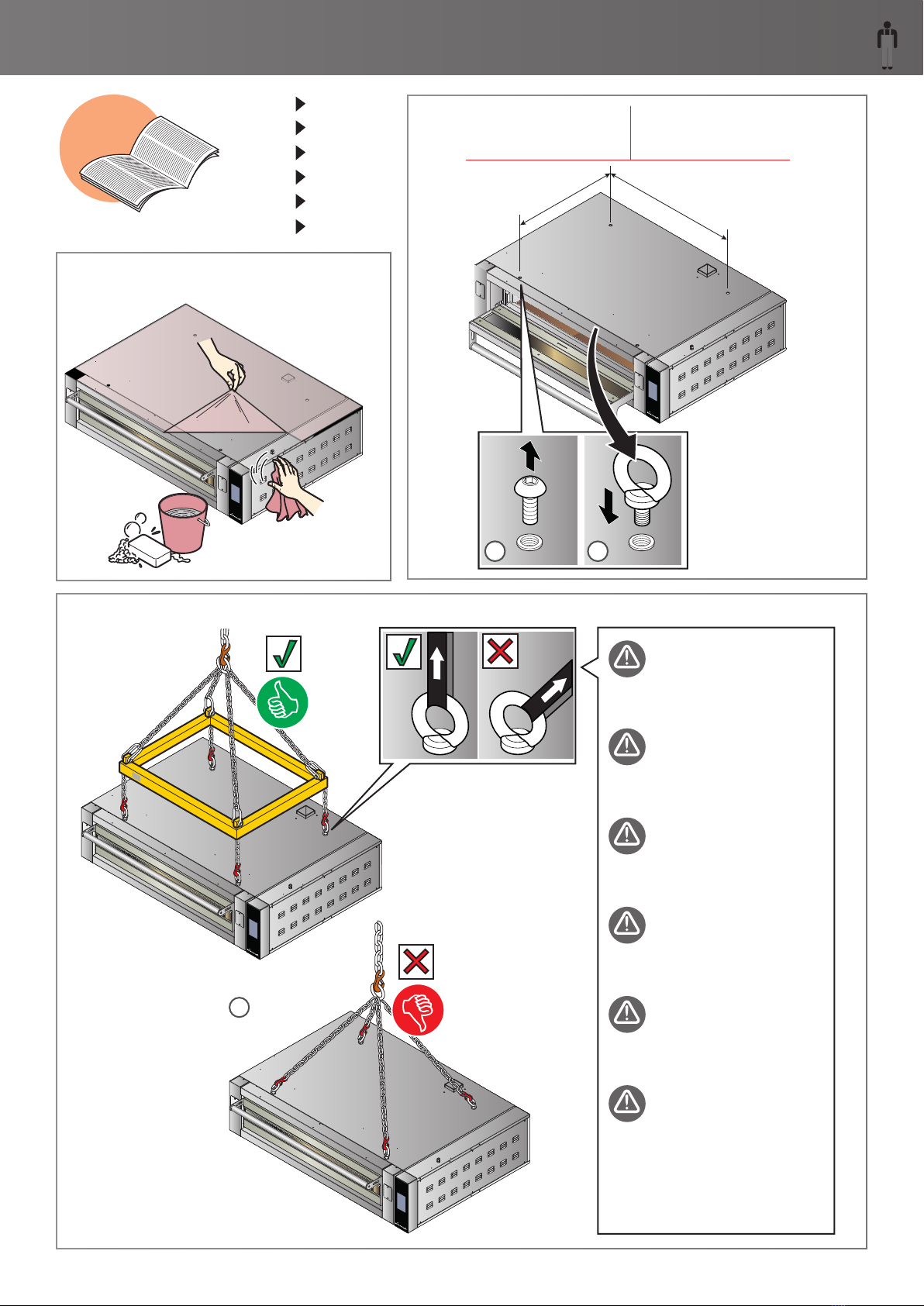

•Before any movement or installation, check

that the room is suitable and systems comply

with the installation country standards and the

specifications indicated on the appliance rating

plate.

•All installation, assembly and non-routine

maintenance operations must be performed

exclusively by qualified technicians that are

authorised by the Manufacturer, in compliance

with the regulations in force in the user country,

and with the regulations on systems and work

safety.

•These appliances are intended to be used for

commercial applications, for example in restaurant

kitchens, canteens, hospitals and commercial

companies such as bakeries, butcher shops, etc.,

but not for the continuous and mass production

of food. A use other than the stated one is

considered improper, potentially dangerous for

people and animals and might permanently

damage the appliance. The improper use of the

equipment shall void the warranty

•Before performing any maintenance, replacing

components or carrying out any routine/

extraordinary cleaning, disconnect the electricity

supply.

•Unauthorised actions, tampering or modifications

that do not follow the information provided in

this manual can cause damages, injuries or fatal

accidents and null and void the warranty.

•It is forbidden to install the oven in environments

at risk of explosion.

•Installation or maintenance that fails to comply

with the instructions in this manual may cause

damage, injury or fatal accidents.

•Persons not involved with the appliance

installation may not pass through or stand in the

work area during appliance assembly.

•The serial plate provides important technical

information. This is vital in case of a request for

maintenance or repair of the equipment: please

do not remove, damage or modify it.

•Failure to follow these regulations may cause

damage or even fatal injury, subsequently

invalidating the guarantee and relieving the

Manufacturer of all liability.

•Caution, suffocation hazard! If left unattended,

packaging could be potentially dangerous for

both children and animals.

•Caution, hindrance hazard! If left unattended,

packaging could hinder vehicles and installers

during assembly operations.

User warnings

• Read this guide carefully before

using and maintaining the

appliance, and keep it with

care in an accessible place for any future

consultation by the various operators.

•Moreover, the manual must always accompany

the product through its life, even in case of transfer.

•Before performing any maintenance, disconnect

the electricity supply.

•Unauthorised actions, tampering or modifications

that do not follow the information provided in

this manual can cause damages, injuries or fatal

accidents and null and void the warranty.

•Use or maintenance that fail to comply with the

instructions in this manual may cause damage,

injury or fatal accidents.

•The serial plate provides important technical

information. This is vital in case of a request for

maintenance or repair of the equipment: please

do not remove, damage or modify it.

•Some parts of the equipment can reach high

temperatures. We recommend you avoid pressing

surfaces and do not get materials either flammable

or sensitive to heat near the appliance.

•Do not rest objects on the oven, above all if built

in material sensitive to heat.

•These appliances are intended to be used for

commercial applications, for example in restaurant

kitchens, canteens, hospitals and commercial

companies such as bakeries, butcher shops, etc.,

but not for the continuous and mass production

of food. A use other than the stated one is

considered improper, potentially dangerous for

people and animals and might permanently

damage the appliance. The improper use of the

Avvertenze di sicurezza