The number of starts should be spread over the hour.

8 - STARTING THE PUMP UNIT

An electro-pump must never be run dry. This is very

important to ensure the mechanical seal remains

watertight.

–For three-phase units, make sure that the direction of

rotation is that indicated by the arrow on the fan cover,

by running the motor for a couple of turns.

–If the direction of rotation is reversed, modify the

connection to the motor terminal block by reversing 2 power

supply wires.

–After starting, once the motor has reached its operating

speed, make sure that the back pressure is normal and

not subject to significant fluctuations. If this is not the

case, stop the electro-pump and check that the level of

liquid in the pan is more than 100 mm above the suction

inlet filter as indicated in section 6.2.

–If the motor is not running fast enough, check the

connection.

–Take care not to leave the pressure valve closed for

more than 5 minutes.

–With the electro-pump operating normally, measure the

maximum current drawn on each phase. Set the circuit-

breaker definitively, for a slightly higher current than the

maximum measured. This must never exceed the current

indicated on the motor identification plate.

–Check that the voltage between phases at the motor

terminals is correct.

–Any disruption to operation indicates abnormal electro-

pump operation (voltage drop, loss of phase, incorrect

setting, foreign body in the pump, sludge, etc.).

–The electro-pump should turn smoothly without

vibrating.

–Never run the electro-pump with the pressure valve

closed.

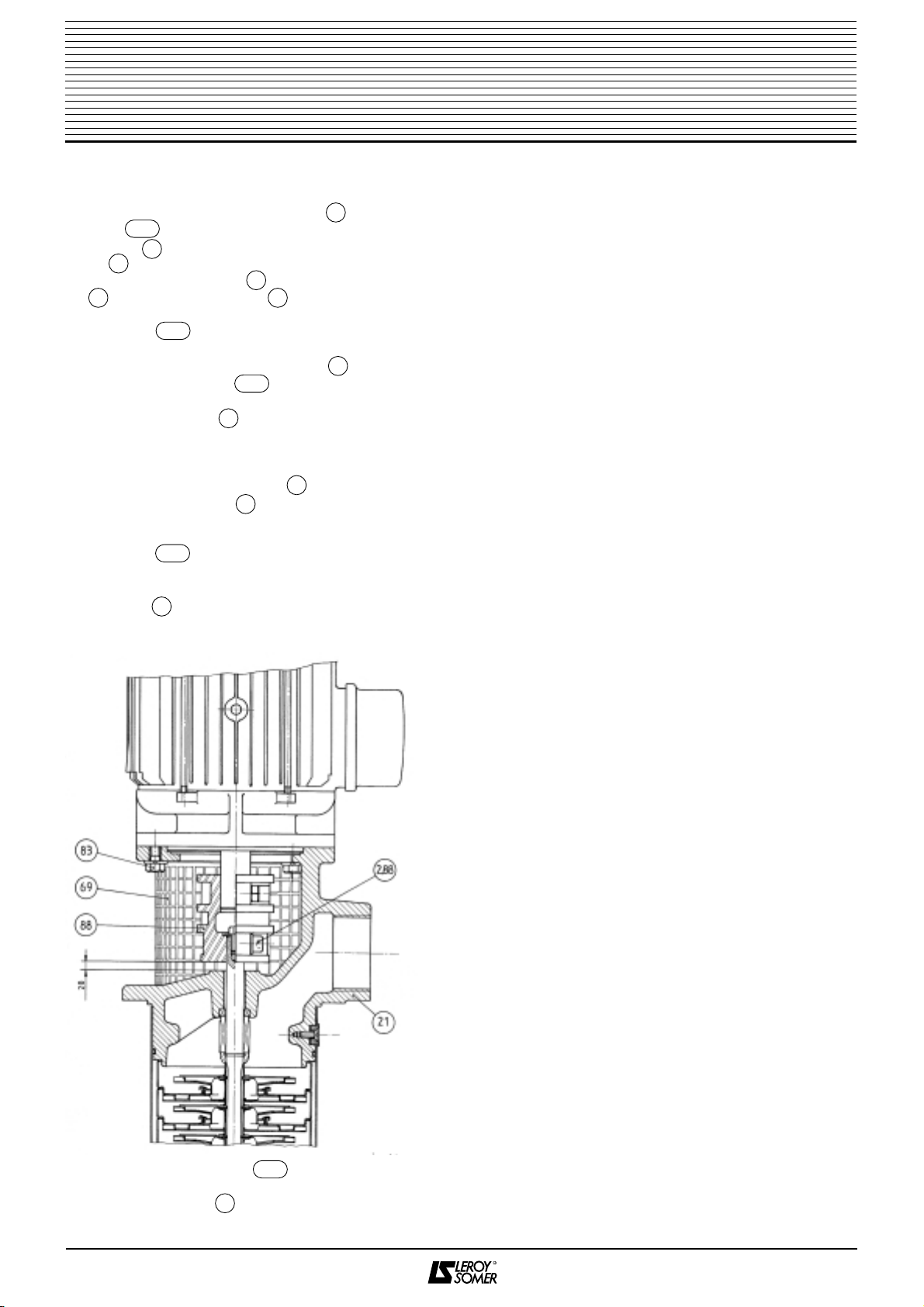

–If difficulties are experienced with priming when the

electro-pump is started, either there is insufficient liquid

in the pan or the pump has been drained and an air

pocket is blocking the top of the pump. In this case,

drain the pump by unscrewing the plug shown in the

diagram at the end of this document.

–Motor. Drain holes: To drain condensates formed

during cooling of the machines, there are holes in the

lowest points in the motor housing or shields depending

on the operating position. From time to time, the plastic

plugs covering these holes should be removed and then

replaced.

9 - STOPPING THE PUMP UNIT

–Switch off the electrical supply to the motor.

–In the event of a prolonged stop and/or where there is

a risk of freezing, drain the pan and the delivery pipe or

take appropriate precautions against freezing.

10 - SERVICING

PV4 and PIV6 series electro-pumps require very little

servicing.

•The bearings are permanently greased.

•Only the mechanical seal may need to be changed if

noticeably worn or leaking.

•Electro-pumps installed as backup equipment should be

run for a short time once a week to ensure that they are

working properly.

It is recommended that the current consumption should

be checked occasionally. If this should rise without

the flow increasing, this indicates an operating fault

or particularly harsh operating conditions, which should be

rectified. In any event, it is recommended that the electro-

pump should be dismantled after 2 years or 10,000 hours

of operation in order to examine parts subject to wear

(mechanical seal, turbine, etc.)

11 - DISMANTLING - REASSEMBLY

An electro-pump must be dismantled and reassembled

by personnel qualified to carry out this type of work.

Where one or more components of the electro-pump are

being replaced (spare parts) it is essential that only parts

supplied by LEROY-SOMER are used. Failure to comply

with this instruction invalidates the guarantee and relieves

the manufacturer of responsibility for any malfunction.

Any person working on an electro-pump is responsible

for the consequences.

Before commencing work on the electro-pump:

–Disconnect the electricity supply to the motor.

–Close the pressure valve.

–Check that the pump body is not under pressure.

11.1 - Removing the motor

The motor can be easily disconnected without removing

the pump.

To do this, remove:

–the protective grille

–the 4 coupling sleeve locking screws

–the 4 screws and their washers

11.2 - Removing the hydraulic unit

After removing the delivery pipe and the fixing for

mounting the pump on the pan, remove the pump from

the pan, drain it and position it vertically with the delivery

head at the bottom.

4

PV4 - PIV6

electro-pumps

Running the electro-pump on empty is

absolutely prohibited.

Motor

power Max. number of starts

per hour

≤0.55 kW 40

0.75 to 1.1 kW 35

1.5 to 3 kW 30

4 to 7.5 kW 20