Leuze electronic GmbH + Co. KG MSI-m(E)/R 3

1 About this document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

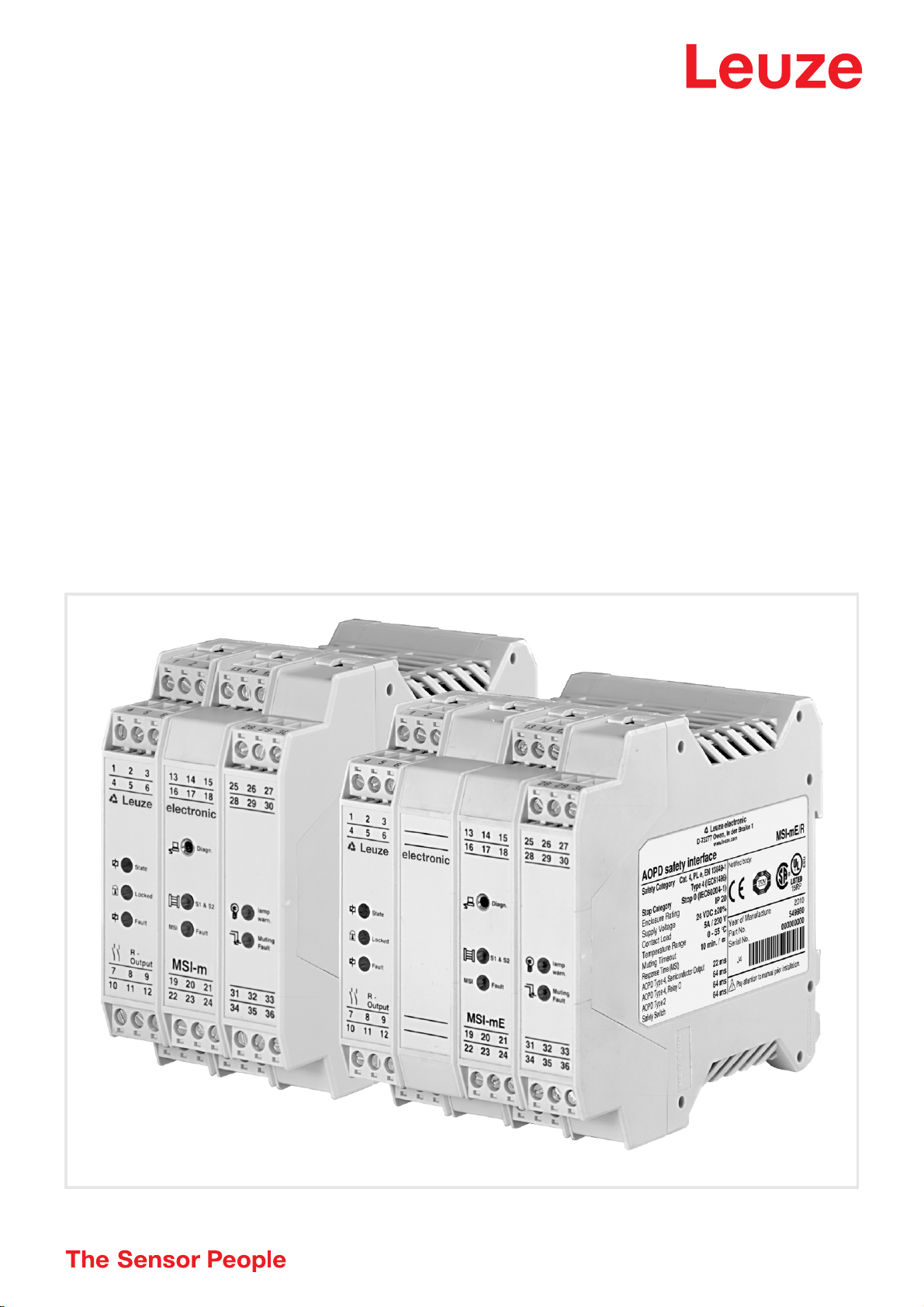

2 System overview and range of applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 General information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Terminology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4 Nomenclature MSI-m(E)/R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 Intended use and foreseeable misuse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1.2 Foreseeable misuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2 Competent personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3 Responsibility for safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.4 Exemption of liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.5 Connection of E-STOP buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.6 Additional safety notices for the special function "Muting" . . . . . . . . . . . . . . . . . . . . . . . . 11

4 System design and functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.1 System design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2 DIP switch settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2.1 MSI-m module DIP switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2.2 I/O-m module DIP switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.3 Operating modes and functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.3.1 Operating modes – interlocking and contactor monitoring functions. . . . . . . . . . . . . . . 13

4.3.1.1 Operating mode: with start/restart interlock – with dynamic contactor monitoring. . . . . 14

4.3.1.2 Operating mode: with start/restart interlock – with static contactor monitoring . . . . . . . 14

4.3.1.3 Operating mode: with start/restart interlock – without contactor monitoring . . . . . . . . . 14

4.3.1.4 Operating mode: without start/restart interlock – without contactor monitoring. . . . . . . 15

4.3.1.5 Operating mode: with start/without restart interlock – without contactor monitoring . . . 15

4.3.2 Muting function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.3.2.1 Sequential muting, connections at M1 to M4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.3.2.2 Parallel muting (2.5 s), connections M2 and M3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.3.2.3 Parallel double muting – with extended version MSI-mx(E)/Rx only . . . . . . . . . . . . . . . 16

4.3.2.4 Testable and non-testable muting sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.3.2.5 Muting display function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.3.2.6 Muting restart while transport material is located in the muting area . . . . . . . . . . . . . . 17

4.3.2.7 Muting time limit - 10 minutes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.3.2.8 Example: Sequential muting, non-testable muting sensors. . . . . . . . . . . . . . . . . . . . . . 18

4.3.2.9 Example: Sequential muting, testable muting sensors . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.3.2.10 Example: Parallel muting, non-testable muting sensors . . . . . . . . . . . . . . . . . . . . . . . . 20

4.3.2.11 Example: Parallel muting, testable muting sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.4 Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.5 Signal outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.6 Diagnostics function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.1 Installation instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.2 Power supply requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.3 Connecting AOPDs, type 4 or type 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.4 Connecting to the machine control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6 Connection examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27