5. SERVICE | REPAIR

5.1 Return

Before every return of your device, whether for recalibration, decalcification, modifications or repair, it has to be cleaned carefully. You

have to enclose a notice of return with detailed defect description when sending the device. If your device came in contact with harmful

substances, a declaration of decontamination is additionally required. Appropriate forms can be downloaded from our homepage

(www.iconprocon.com). Should you dispatch a device without a declaration of decontamination and if there are any doubts in our

service department regarding the used medium, repair will not be started until an acceptable declaration is sent.

The warranty conditions are subject to the legal warranty period of 12 months from the date of delivery. In case of improper use,

modifications of or damages to the device, we do not accept warranty claims. Damaged diaphragms will also not be accepted.

Furthermore, defects due to normal wear are not subject to warranty services.

7. WARRANTY CONDITIONS

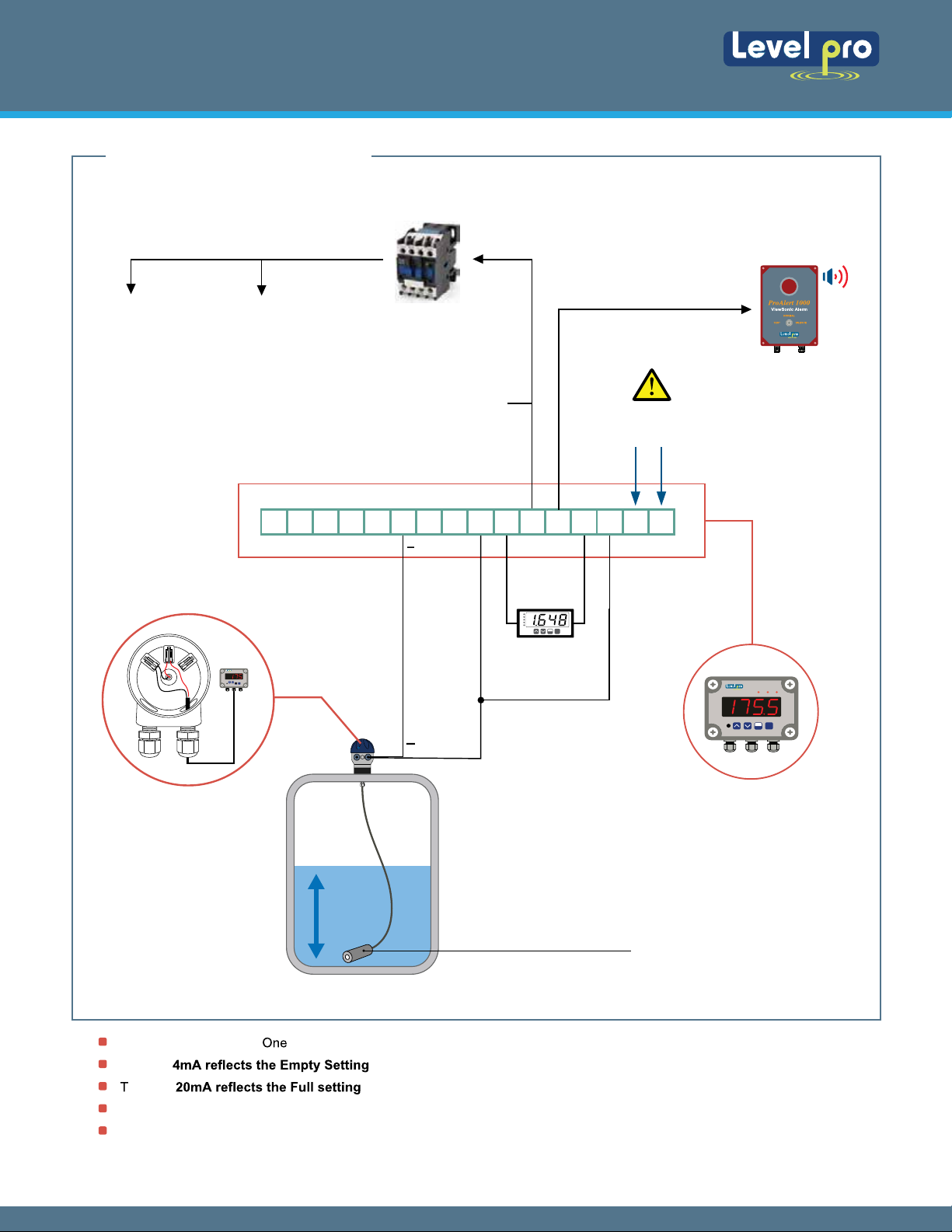

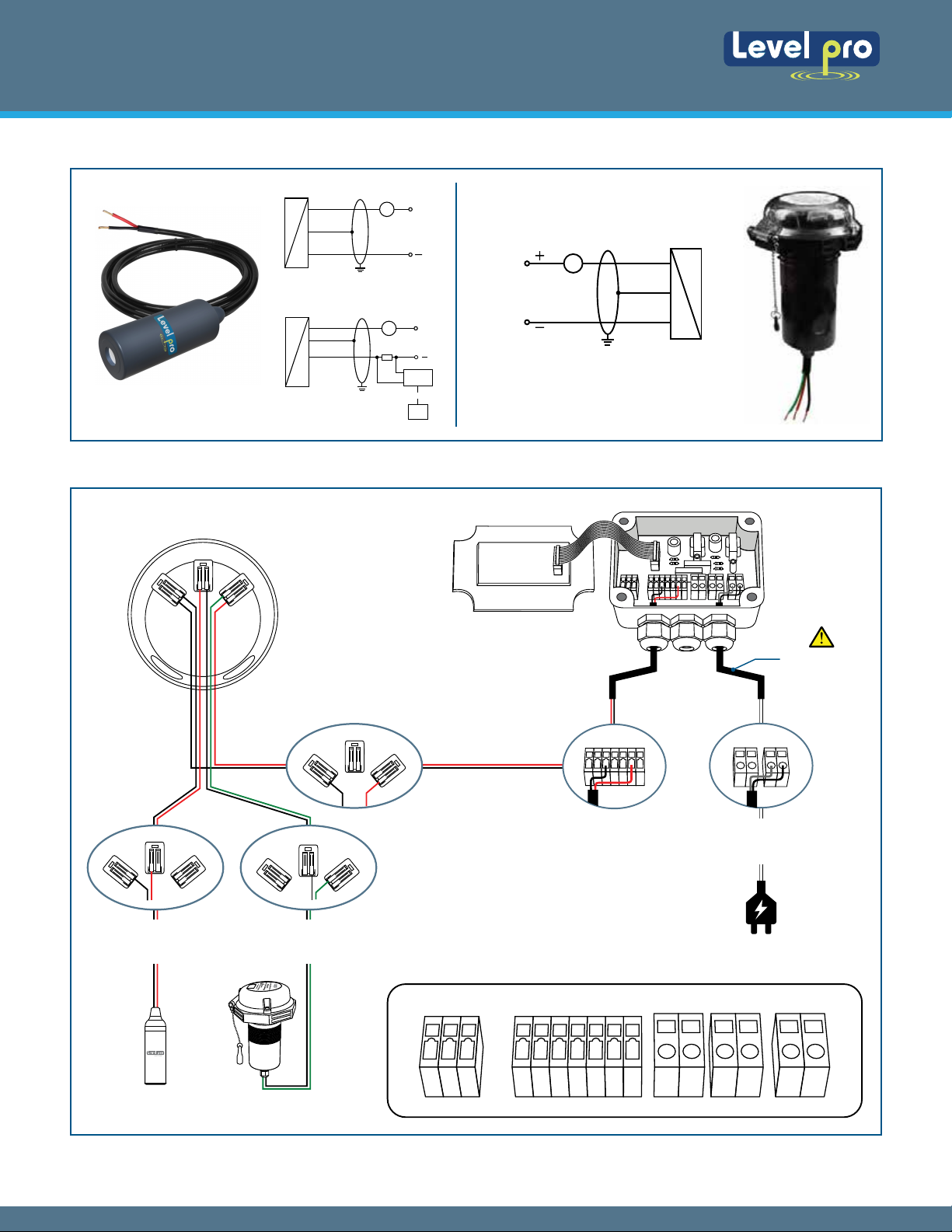

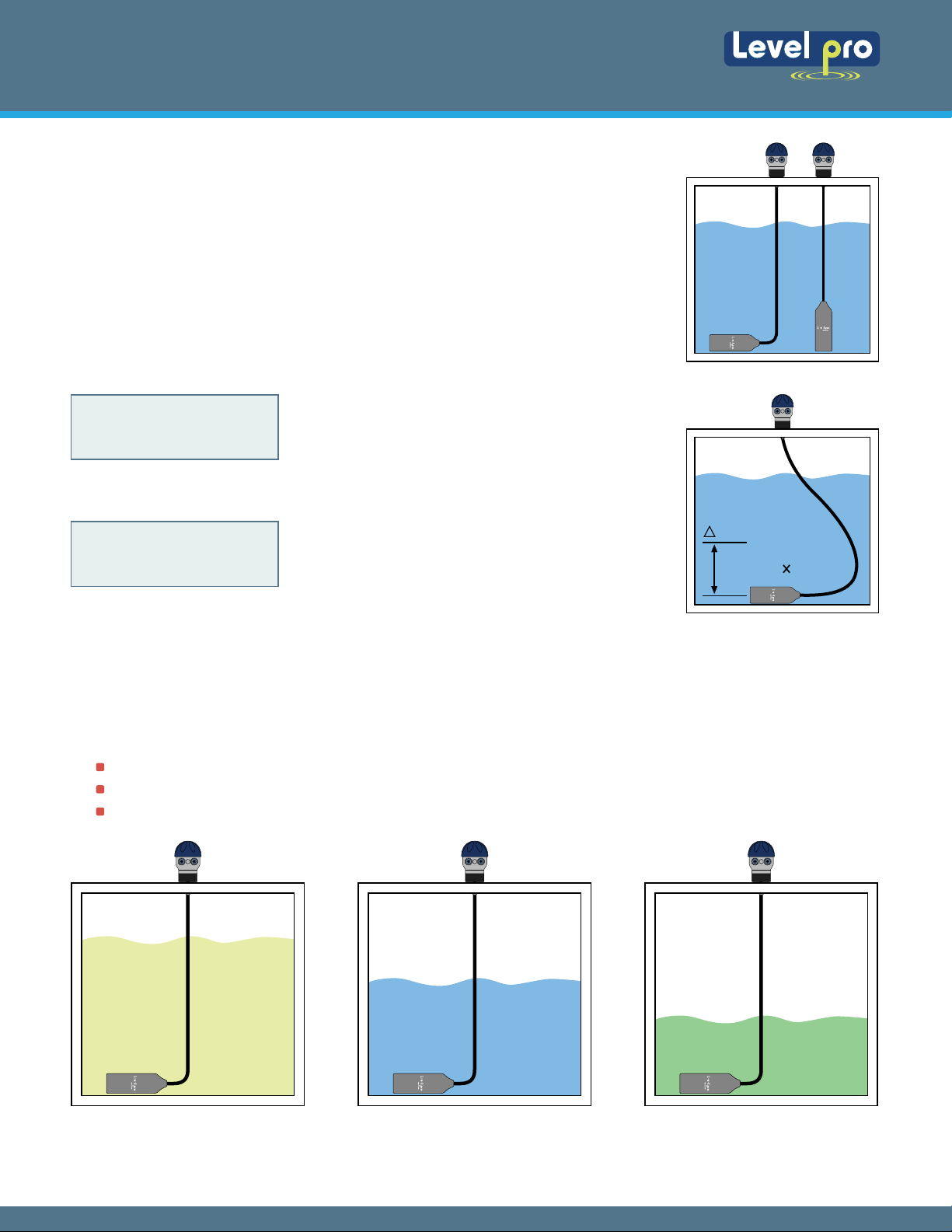

The Levelpro pressure transmitter is placed near or on the bottom of the tank. A ceramic pressure diaphragm within the pressure

transmitter is exposed on one side to the application liquid. The other side is exposed to the reference pressure via a small ventilation

tube located inside of the cable. The difference in pressure between liquid and reference pressures will slightly deflect the diaphragm.

The deflection of the diaphragm is measure by a built-in microprocessor located inside the ceramic diaphragm.which is converted into a

4-20mA two wire current signal proportional the height of the liquid. Make sure that Levelpro Transmitter is compatible with the

application liquid media.

TECHNOLOGY

SAFETY PRECAUTIONS

About this Manual : PLEASE READ THE ENTIRE MANUAL PRIOR TO INSTALLING OR USING THIS PRODUCT. This

manual includes information on all versions of the Levelpro Pressure Level Transmitters Please refer to the part number

located on the transmitter label to verify the exact model which you have purchased.

User's Responsibility for Safety : Levelpro offers a wide range of liquid level sensors and technologies. While each of

these technologies are designed to operate in a wide variety of applications, it is the user's responsibility to select a

technology that is appropriate for the application, install it properly, perform tests of the installed system, and maintain all

components. The failure to do so could result in property damage or serious injury.

Proper Installation and Handling : Only properly-trained staff should install and/or repair this product.

Wiring and Electrical : CAUTION - Do not exceed specified supply voltage rating of 30 VDC. Permanent damage not

covered by warranty will result. This device is not designed for 120 or 240 volt AC operation. Use only the specified

voltage found in the specification sections.

Temperature and Pressure : TheLevelpro series are designed for use in the specified application temperatures referred

to in the specification section.

Material Compatibility : Make sure that the model which you have selected is chemically compatible with the application

liquids.

Make a Fail-Safe System : Design a fail-safe system that accommodates the possibility of transmitter failure or battery

power loss. In critical applications, Levelprorecommends the use of redundant backup systems and alarms in addition to

the primary system.

If the device came in contact with hazardous substances, certain precautions have to be complied with for purification!

The device must be disposed according to the European Directives 2002/96/EG and 2003/108/EG (on waste electrical and

electronic equipment) Waste of electrical and electronic equipment may not be disposed by domestic refuse!

6. DISPOSAL

WARNING!Depending on the measuring medium, deposit on the device may cause danger for the user and

the environment. Comply with adequate precau-tions for purification and dispose of it properly.

ContinuousSubmersibleLevel Transmitter

Levelpro-Sensors Manual

06

© Icon Process Controls Ltd. All Rights Reserved