4 | Sump Pump Control System

Important Safety Information

SAVE THESE INSTRUCTIONS

Carefully read this manual before installing or using this product. Failure to understand and follow this

manual may result in personal injury, electrical shock, and/or fire.

SAFETY SYMBOLS & SIGNAL WORDS

Read and Understand these types of Warnings:

DANGER: means that someone will be injured or killed if the safety information is not followed.

WARNING: means that someone could be injured or killed if the safety information is not followed.

NOTICE: means that property or equipment damage may result if instructions are not followed.

Personal Safety

DANGER: This installation involves use of high-voltage electricity in a wet environment, so please use

common sense and caution.

You can safely install the LevelGuard™Sump Pump Control ONLY IF YOU:

• Contact a qualified electrician immediately if sump area is wet or flooded. Do not walk on or touch

wet areas until all power is disconnected from pump electrical outlet.

• DO NOT touch the sump pump or discharge piping when the pump is connected to electrical

power and water is present in the sump pit. Always disconnect the pump from the power source

before handling.

• Do not install this product while impaired in any way.

• Do not allow by-standers, children, or pets to come near the installation or cause distraction.

• Keep loose clothing and jewelry away from electrical parts. Use non-skid shoes and proper

eye protection.

• Do not operate this electrical device in an explosive atmosphere, such as in the presence of

flammable liquids, gases, or dust. The LevelGuard Sump Pump Control is sealed and solid-state, but

the pump motor can create sparks that may ignite dust or fumes.

Equipment and Electrical Safety

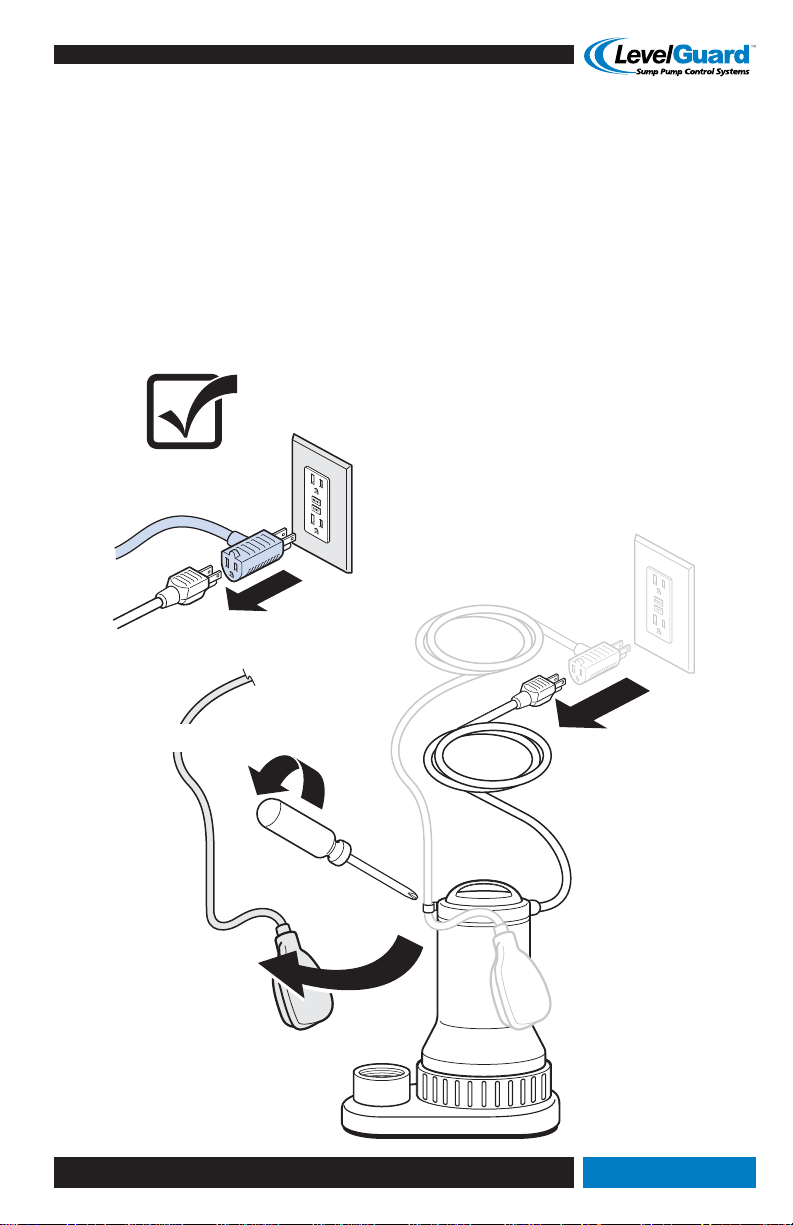

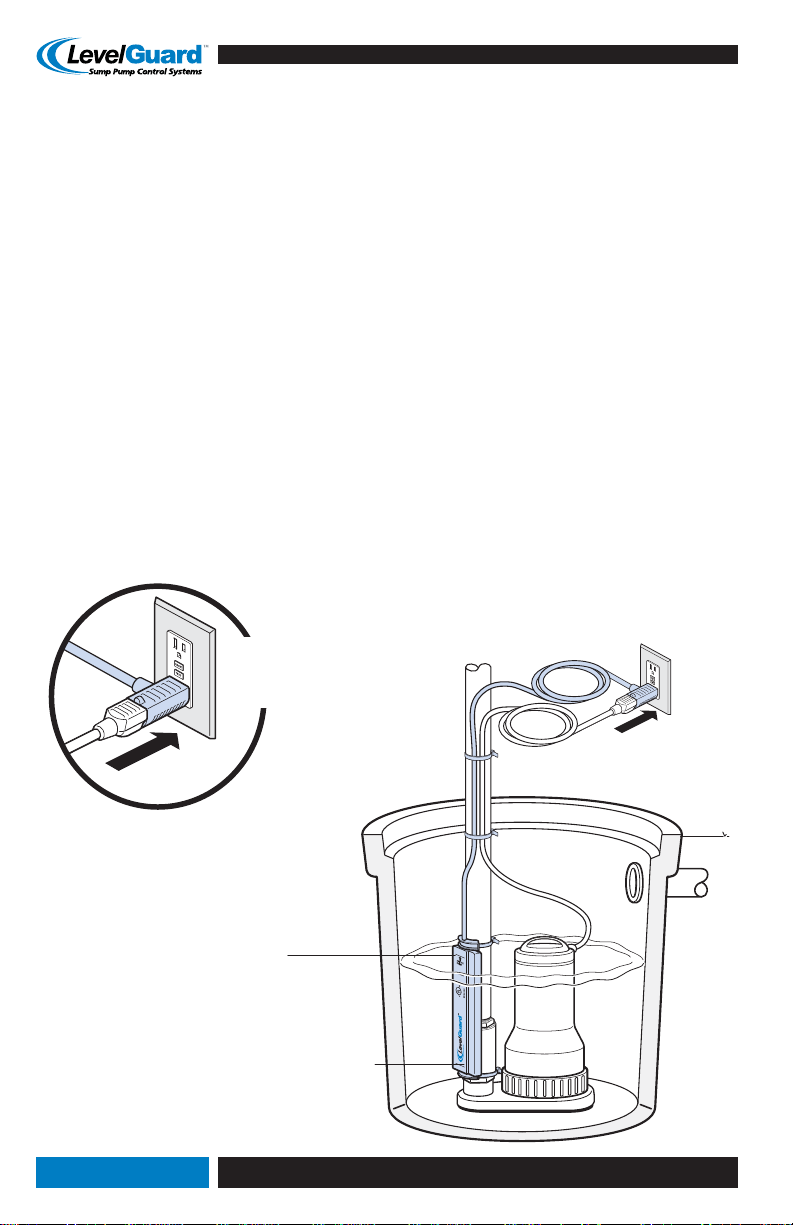

• Plug the LevelGuard Sump Pump Control ONLY into a properly grounded, Ground Fault Circuit

Interrupt (GFCI) receptacle.

NOTICE: These instructions assume that local code enforcement requires the use of a GFCI receptacle.

(Codes may vary by geographical jurisdiction.)

• GFCI receptacle must be installed by qualified electrician in accordance with all applicable codes

and ordinances.

• Before LevelGuard Sump Pump Control installation, a qualified person must test the GFCI to assure

that it is operating properly.

• Never remove the grounding prong; never modify the plug or GFCI in any way; do not use any

adapter plugs.

• Keep cord away from sharp edges, heat, oil, or moving parts. Discontinue use immediately if cord

is damaged.