The door must be made of connuous corrugated sheet construcon and spring

balanced

Door Axle diameter must not exceed 35mm

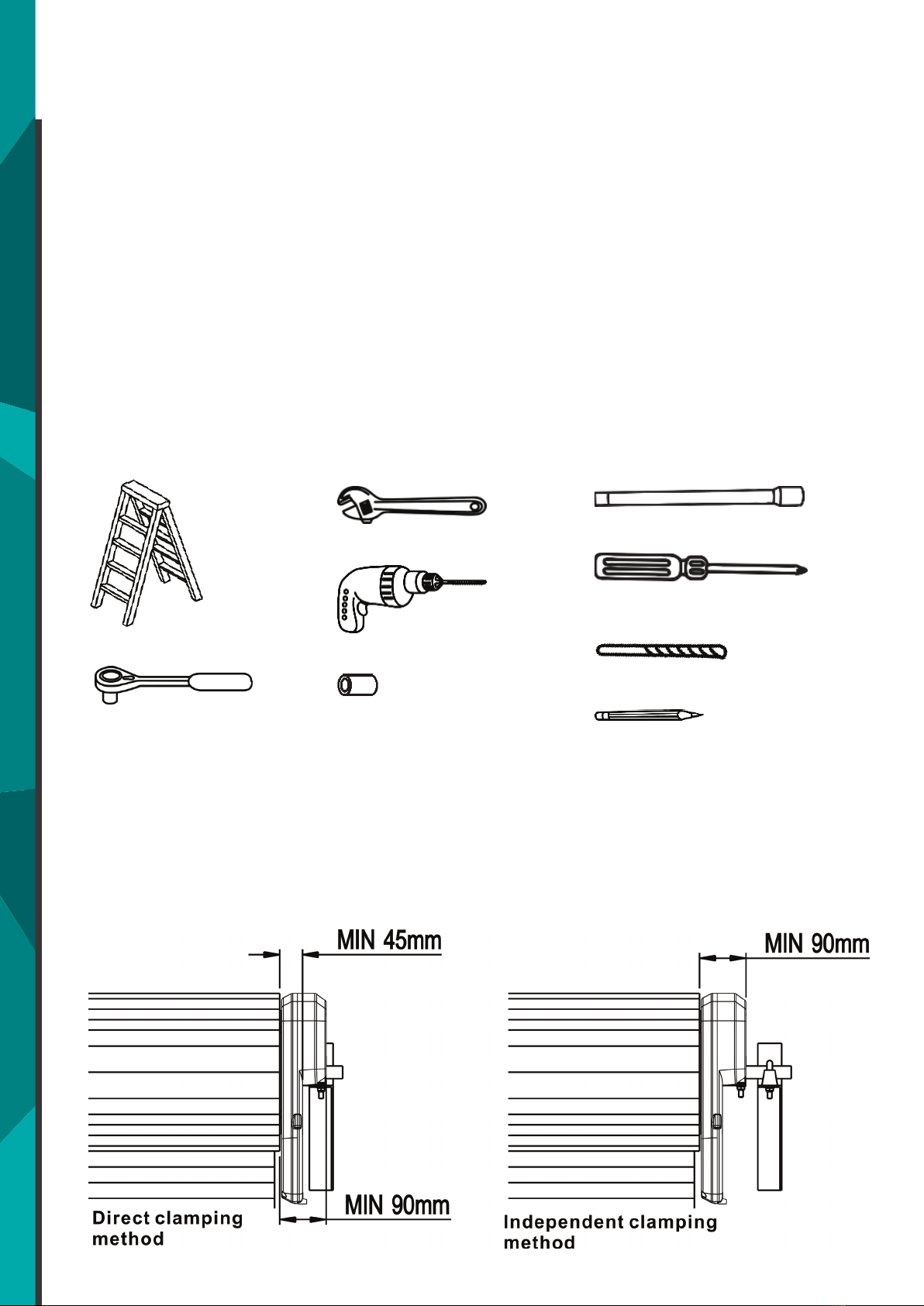

Ensure that there is at least 45mm from the edge of the curtain to the edge of

the bracket.

Ensure there is a power point near the opener. Portable Power Generators are

not recommended.

If the roller door drum is on the edge of the curtain or is a smaller diameter,

addional clearance may be required.

If the drum is more than 60mm from the curtain edge or of a smaller diameter,

an extension pole kit may be required (secon 5.7)

5. DOOR PREPARATION

Complete the following test to ensure

that your door is well balanced, and not

scking or binding.

• Disable all locks and remove any

ropes connected to the garage door.

• Li the door to about halfway and

then release it. The door should

remain spring balanced.

• Raise and lower the door to

determine if there are any scking

or binding points (20kgf is the

absolute maximum allowable to

raise or lower the door in any

posion).

• Clean the Guides of any oil or wax built up

• Install locking bar covers if there are locking bar holes in the guides. This

ensures fingers cannot be placed in the holes while the door operates

• Place included warning label so they are visible on the inside of the door

If your door does not hold in place or the door binds or sticks, have your roller door

attended to by a qualified technician before installing the Roller door opener.

5.1 Testing the door

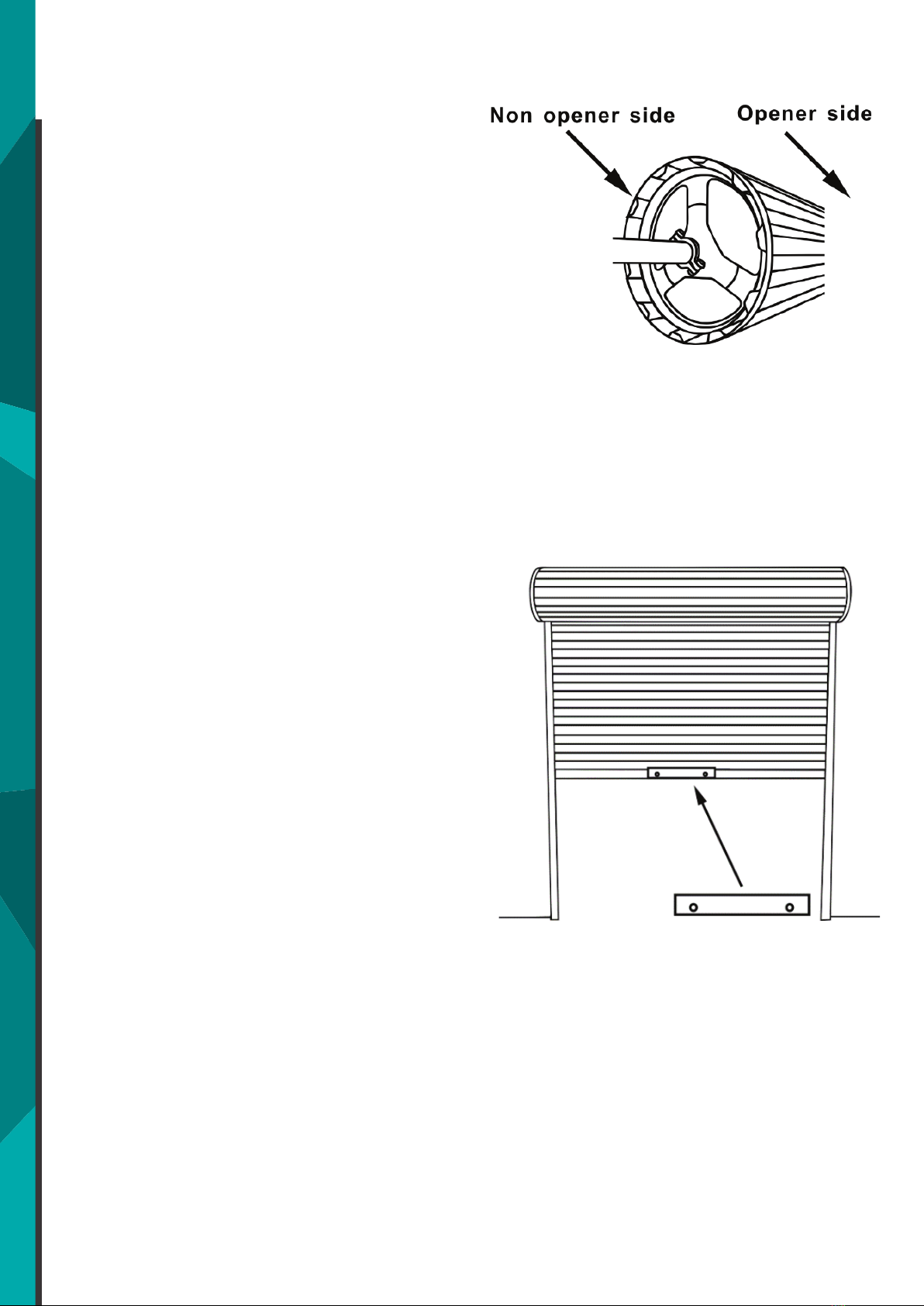

• Install the stop collar on the

opposite end to where the opener is

going to be installed.

ie – Right hand installation – Stop Collar

will be on the Left Hand side.

• Fit the stop collar hard against the

boss of the door drum.

• Ensure the U-Bolt holding the door

sha to the door bracket is ghtly

secured.

5.3 Installing the Weight Bar

If your roller door has a handle, a weight

bar is required to be installed prior to

installing the motor.

Garage door has existing handle:

• Remove the Handle, Nuts and Bolts.

• Place the weight bar over the handle

holes in the centre of the door on

the inside.

• Insert Extended Bolts through the

weight bar

• Fasten handle back in place

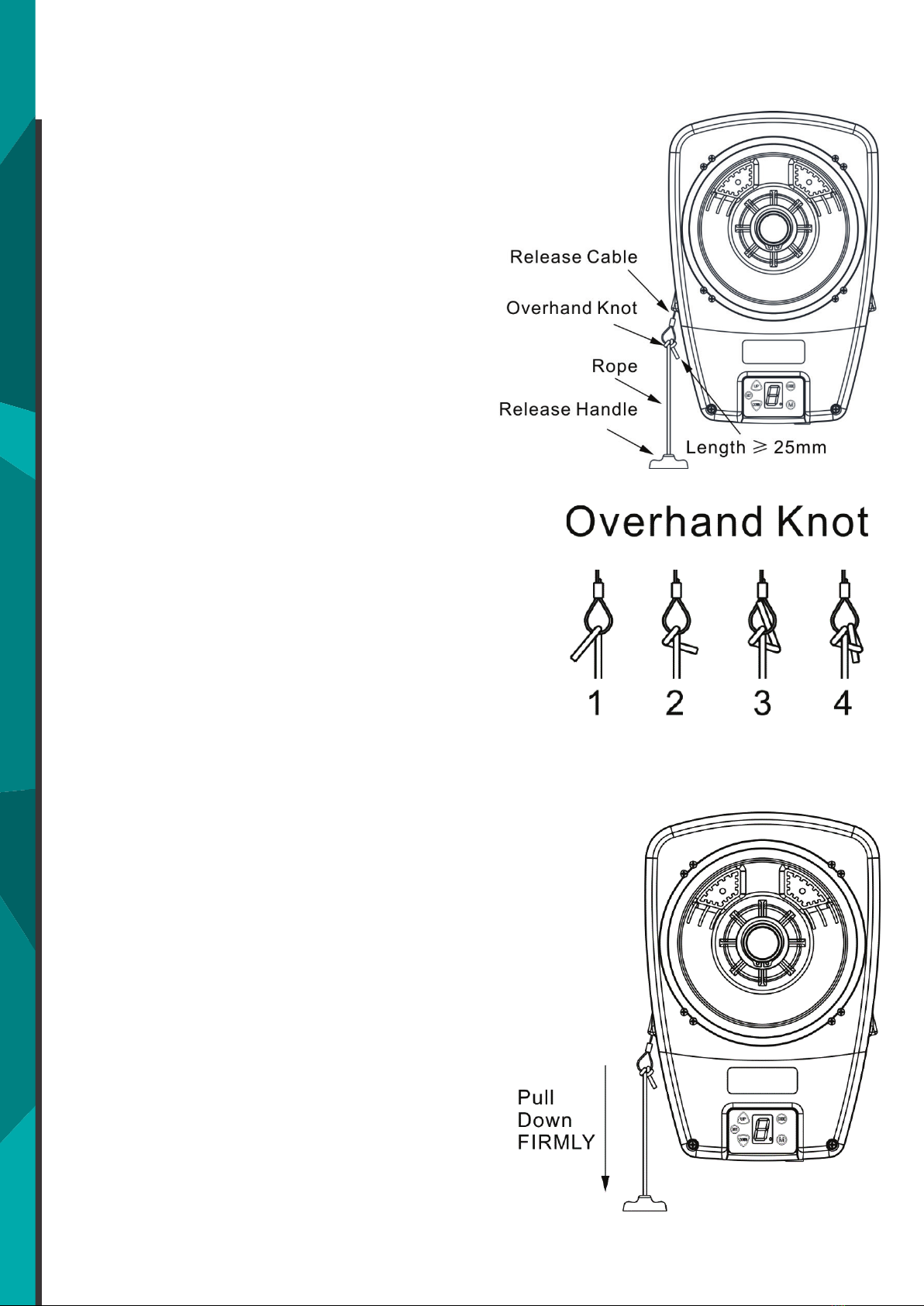

• Thread one end of the rope through

the hole in the top of the red

release handle so that “NOTICE”

reads right side up

• Secure with an overhand knot at

least 25mm from the end of the

rope to prevent slipping.

• Thread the other end of the rope

through the loop of the manual

release cable.

• Adjust rope length so the handle

(when installed) will be no higher

than 1.8m above the floor.

• Secure with an overhand knot.

Final adjustment of handle height

should be completed aer the opener is

installed. If it is necessary to cut the

rope, heat seal the cut end to prevent

unravelling.

Disengaging the Opener

• Pull the release cord down firmly

Re-engage the opener

• Pull the release cord down firmly

Disable all locks and remove any ropes

connected to the garage door. Take

care when operang the manual release

as an open door may fall rapidly due to

weak or broken springs or being out of

balance.

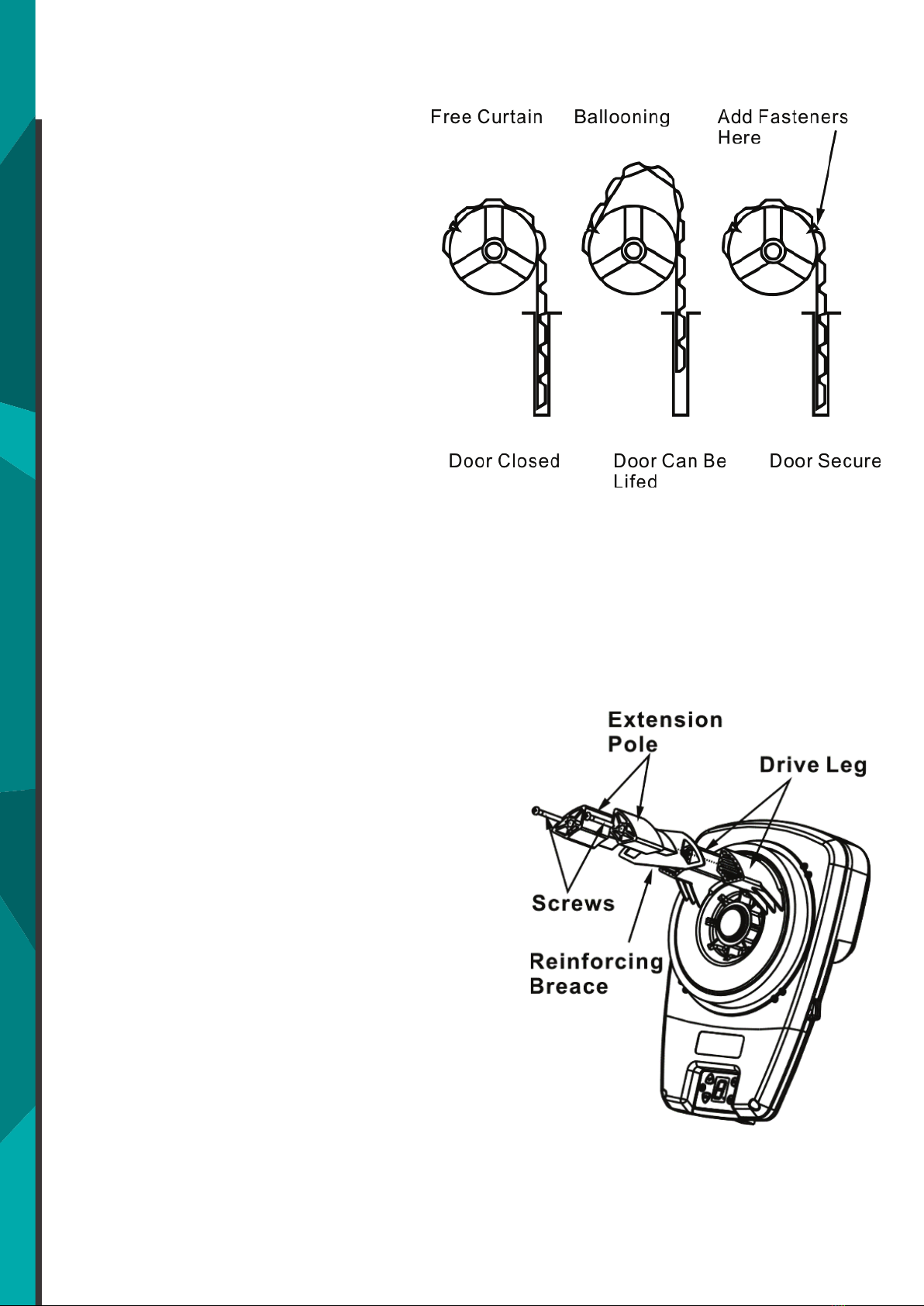

5.6 Pinning the Door

Pinning the rolling garage doors

curtain to the drum maintains

security when the opener is

closed and can affect the safety

reversal response. If the

curtain is not pinned the door

can be parally opened

manually.

• Close roller door fully

• Place self tapping metal

screws or rivets where the

curtain leaves the roll.

• Secure these through the

This accessory in not included in

standard package.

• Align the extension pole holes with

the drive legs.

• Slide the reinforcing brace over the

poles.

• Insert the extension poles into the

drive leg and fix in place using

screws provided.

Reinforcing brace MUST be used.

© LEXO Automaon Pty Ltd 2019 | www.lexo.com.au | Model RD1P1000A | Page 5/22