Contents

300692481_002_C0 – 08/2018 – © Leybold 5

Section Page

1

Introduction............................................................................................................ 9

1.1

Scope and definitions............................................................................................................... 9

1.2

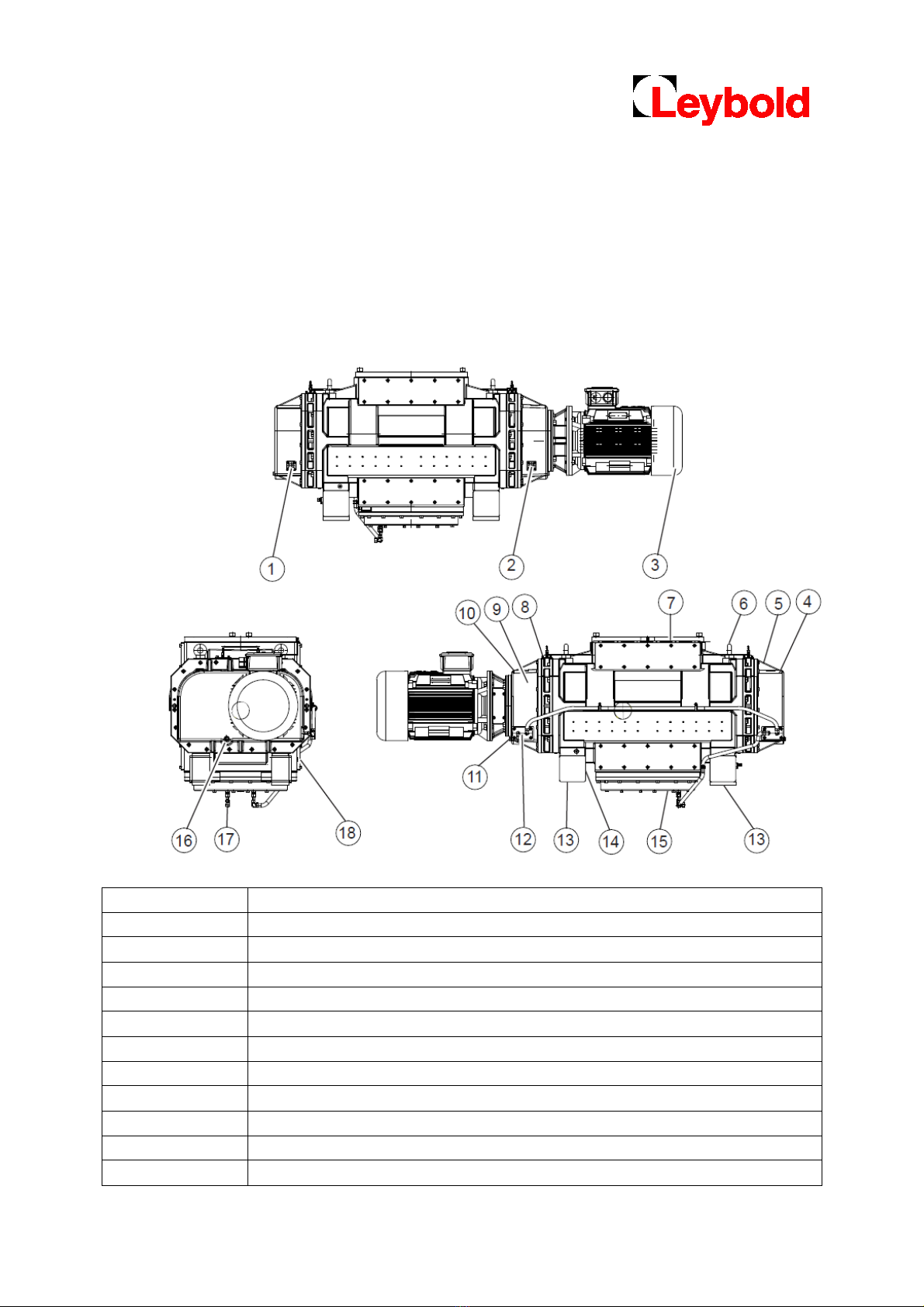

Description ............................................................................................................................. 10

1.3

Application.............................................................................................................................. 11

1.4

Normal operation.................................................................................................................... 11

1.5

Abnormal operation ................................................................................................................ 12

2

Technical data...................................................................................................... 13

2.1

Operating and storageconditions........................................................................................... 13

2.2

Critical backing pressure........................................................................................................ 13

2.3

Performance........................................................................................................................... 14

2.4

Cooling water supply and seal purge gas supply................................................................... 14

2.5

Mechanical data ..................................................................................................................... 15

2.6

Lubrication data...................................................................................................................... 15

2.7

Electrical data......................................................................................................................... 15

2.8

Connections ........................................................................................................................... 15

2.9

Noise and vibration data ........................................................................................................ 16

2.10

Materials of construction ........................................................................................................ 16

3

Installation............................................................................................................ 19

3.1

Installation safety.................................................................................................................... 19

3.2

Unpack and inspect................................................................................................................ 19

3.3

Mechanical installation ........................................................................................................... 20

3.3.1 Locate the pump....................................................................................................................................20

3.3.2 Motor installation for bareshaft variant...................................................................................................20

3.4

Motor electrical connections................................................................................................... 21

3.4.1 Connect the electrical supply .................................................................................................................22

3.4.2 Connect the motor thermistors ..............................................................................................................22

3.4.3 Connect the PT 100...............................................................................................................................22

3.5

Earth (ground) connection...................................................................................................... 23

3.6

Connect the cooling water pipelines ...................................................................................... 23

3.7

Check the direction of rotation ............................................................................................... 24

3.8

Connect the pump inlet and outlet ......................................................................................... 24

3.9

Commission the RUVAC WA 40000 pump............................................................................ 25

4

Operation ............................................................................................................. 26

4.1

Operational safety .................................................................................................................. 26

4.2

Start-up................................................................................................................................... 27

4.2.1 Pre-start checks .....................................................................................................................................27

4.2.2 Start-up..................................................................................................................................................27

4.3

Shutdown ............................................................................................................................... 27

5

Maintenance......................................................................................................... 28

5.1

Safety information .................................................................................................................. 28

5.2

Maintenance plan................................................................................................................... 29

5.3

Inspect the oil level................................................................................................................. 29

5.4

Top up the end cover oil level ................................................................................................ 30

5.5

Inspect the system installation ............................................................................................... 30

5.6

Change the oil ........................................................................................................................ 31

5.6.1 Drive end cover .....................................................................................................................................31

5.6.2 Non-drive end cover ..............................................................................................................................31

5.7

Replace the pump motor........................................................................................................ 32

5.7.1 Remove the pump motor .......................................................................................................................32

5.7.2 Fit the new pump motor.........................................................................................................................33