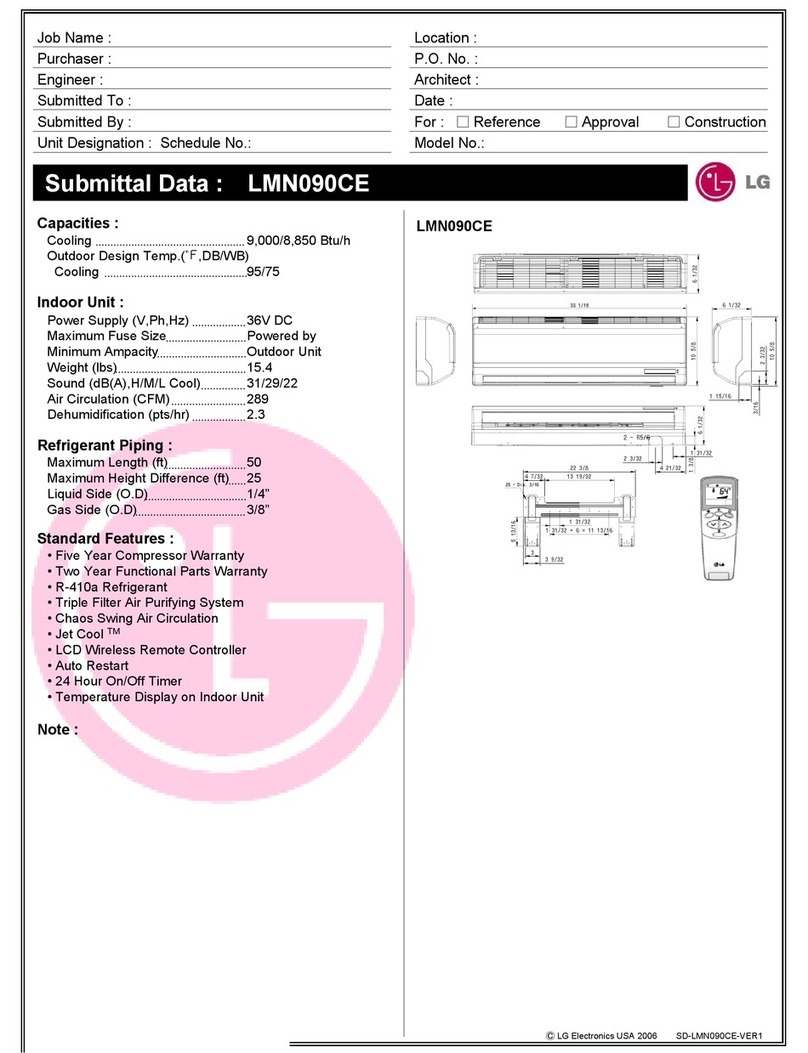

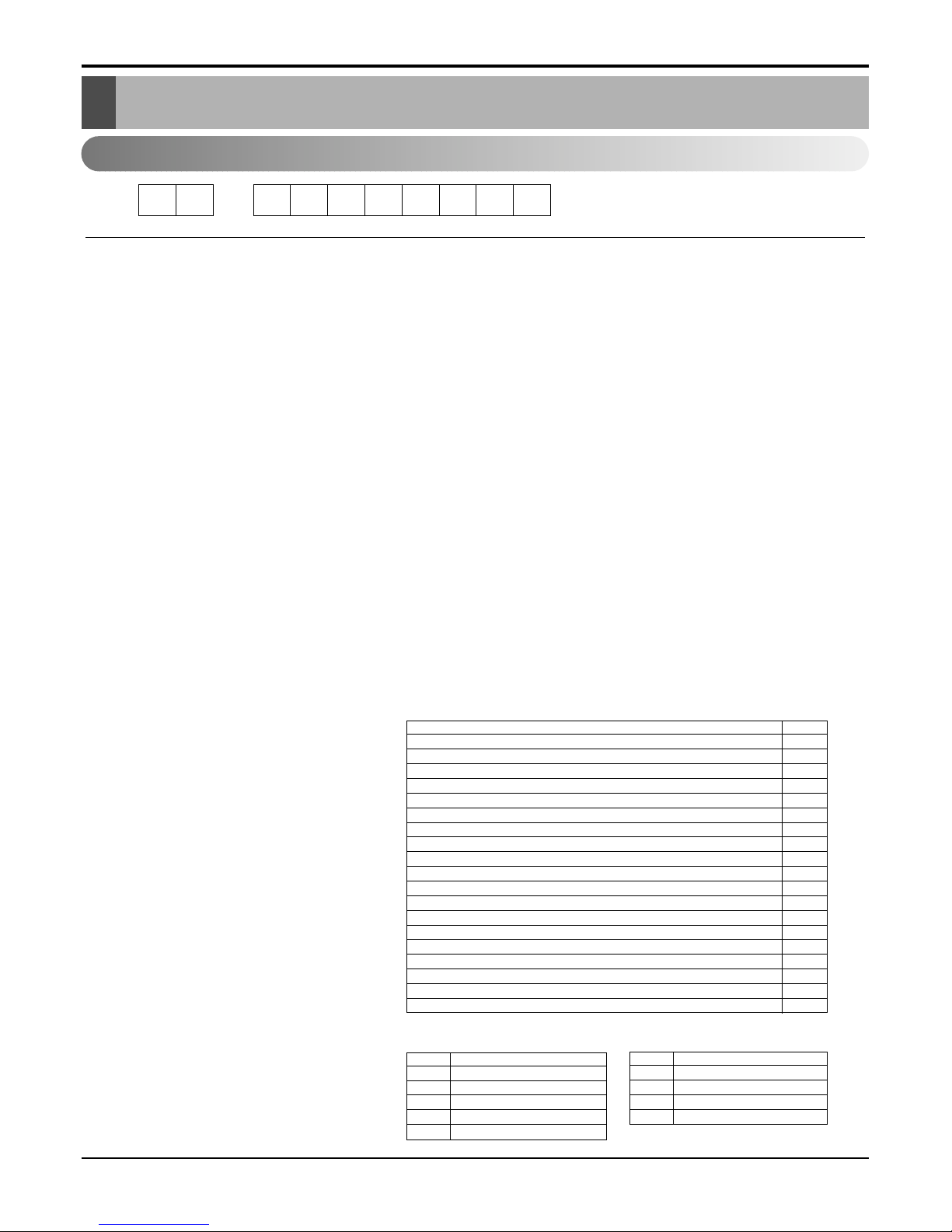

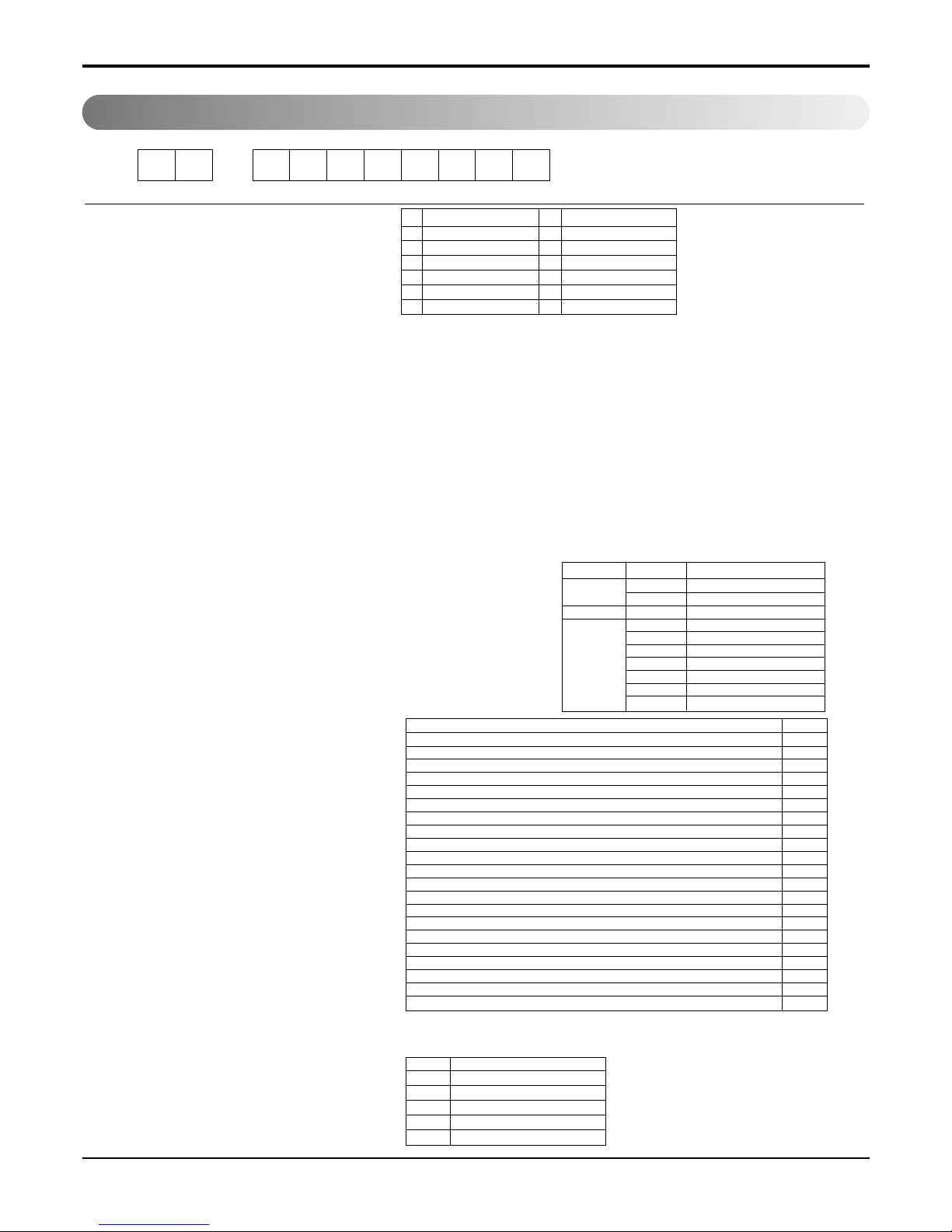

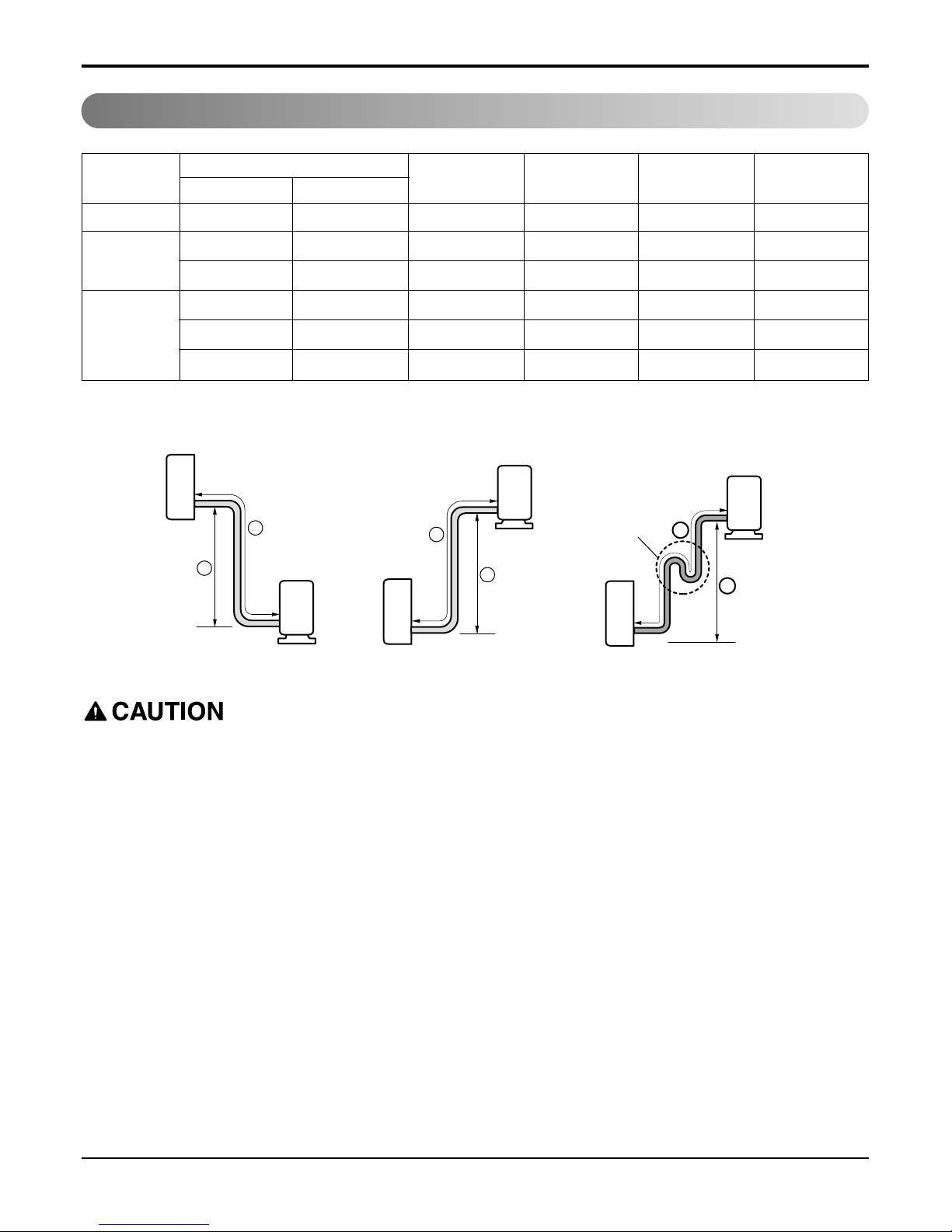

12 -345678910

Code Type Code of Model Meaning

1 Producing Center, A~Z L: Chang-won R22 N: India

Refrigerant A: Chang-won R410A Z: Brazil

C: Chang-won R407C D: Indonesia

T: China M: Mexico

K: Turkey R22 V: Vietnam

E: Turkey R410A S: Out Sourcing

H: Thailand

2 Product Type A~Z S: Split Type Air Conditioner

3 Cooling/Heating/Inverter A~Z C: Cooling only

H: Heat pump

X: C/O + E/Heater

Z: H/P + E/Heater

V: AC Inverter C/O

N: AC Inverter H/P

Q: DC Inverter C/O

W: DC Inverter H/P

4, 5 Capacity 0~9 Cooling/Heating Capacity

Ex. "09" →9,000 Btu/h

6 Electric Range 1~9 1: 115V/60Hz, A: 220V, 50Hz, 3Phase

A~Z 2: 220V/60Hz B: 208~230V, 60Hz, 3Phase

3: 208-230V/60Hz C: 575V, 50Hz, 3Phase

5: 200-220V/50Hz D: 440~460, 60Hz, 3Phase

6: 220-240V/50Hz E: 265V, 60Hz

7: 110V, 50/60Hz F: 200V, 50/60Hz

8: 380-415V/50Hz

9: 380-415V/60Hz

7 Chassis A~Z Name of Chassis of Unit

Ex. 4 →S4 Chassis

8 Look A~Z Look,

Color (Artcool Model)

9 Function A~Z

10 Serial No. 0~9 LG Model De

* ARTCOOL COLOR

velopment Serial No.

Basic A

Basic+4Way B

Plasma Filter C

Plasma Filter+4 Way D

Tele+LCD E

Tele+LCD+Nano plasma+4Way F

Nano Plasma F+(A/changeove)+A/clean+Low A G

Nano Plasma F+(A/changeove)+A/clean+4way+Low A H

Tele+LED+4way I

Internet J

Plasma F+4Way+Oxy generator K

Nano Plasma F+(A/changeove)+A/clean L

Nano Plasma F+(A/changeove)+A/clean+4way M

Nano Plasma F+(A/changeove)+A/clean+PTC N

Nano Plasma F+(A/changeove)+Autoclean+4way+PTC P

Nano Plasma F+(A/changeove)+A/clean+4way+Low A+PTC Q

Negative ION+A/Clean R

(Nano)Plasma+Negative ION+A/Clean S

4way+(Nano)Plasma F+Negative ION+Healthy dehumidification+A/Clean

T

Nano Plasma F+4Way+(A/changeove)+A/clean+ U

R Mirror

W White

B Blue

D Wood

M Metal

C Cherry

N Walnut

A Gogh

S Sisley

Q Quran

K Mecca