LG LM-3061H2L/M User manual

Other LG Air Conditioner manuals

LG

LG LSU181HSV User manual

LG

LG LP-E5020CL User manual

LG

LG AS-H306DGM0(S30AHP-ND6/UD6) User manual

LG

LG LS120HEV1 User manual

LG

LG LV-B1864CL Operation manual

LG

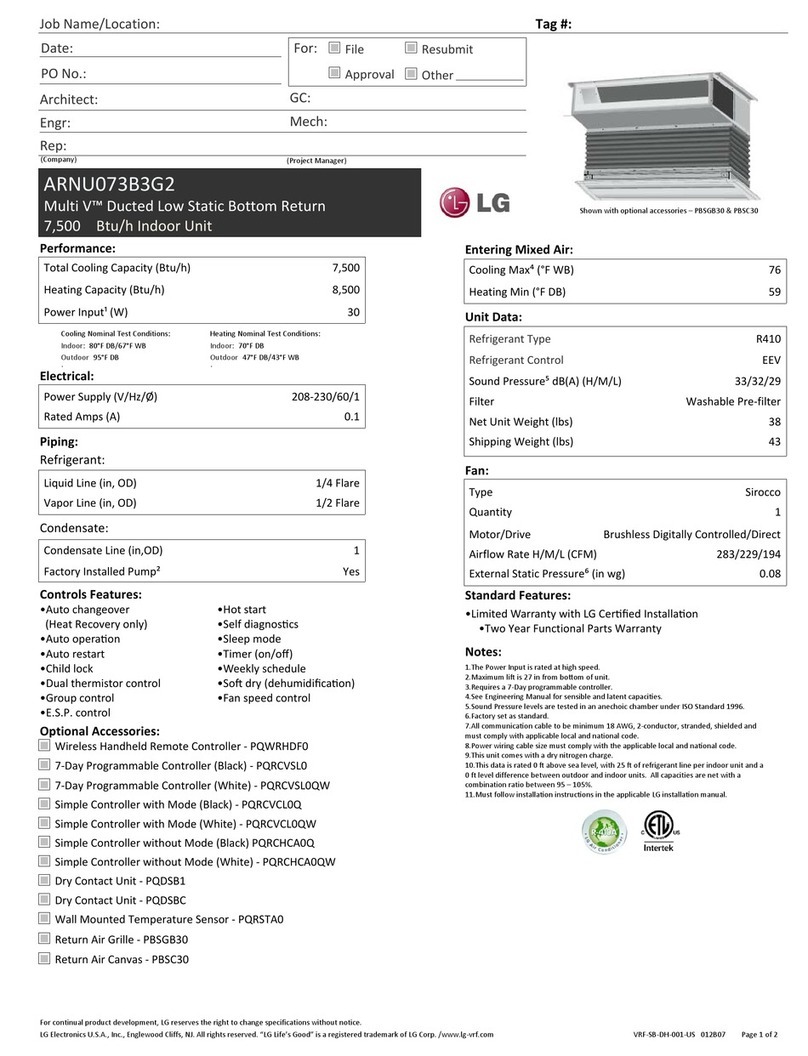

LG Multi V ARNU073B3G2 User manual

LG

LG Multi-Inverter Type User manual

LG

LG MULTI V VJ Series User manual

LG

LG MFL50024826 User manual

LG

LG LS-L1261CL User manual

Popular Air Conditioner manuals by other brands

CIAT

CIAT Magister 2 Series Installation, Operation, Commissioning, Maintenance

Bestron

Bestron AAC6000 instruction manual

Frigidaire

Frigidaire FFRE0533S1E0 Use & care guide

Samsung

Samsung AS09HM3N user manual

Frigidaire

Frigidaire CRA073PU11 use & care

Soleus Air

Soleus Air GB-PAC-08E4 operating instructions