—4 —

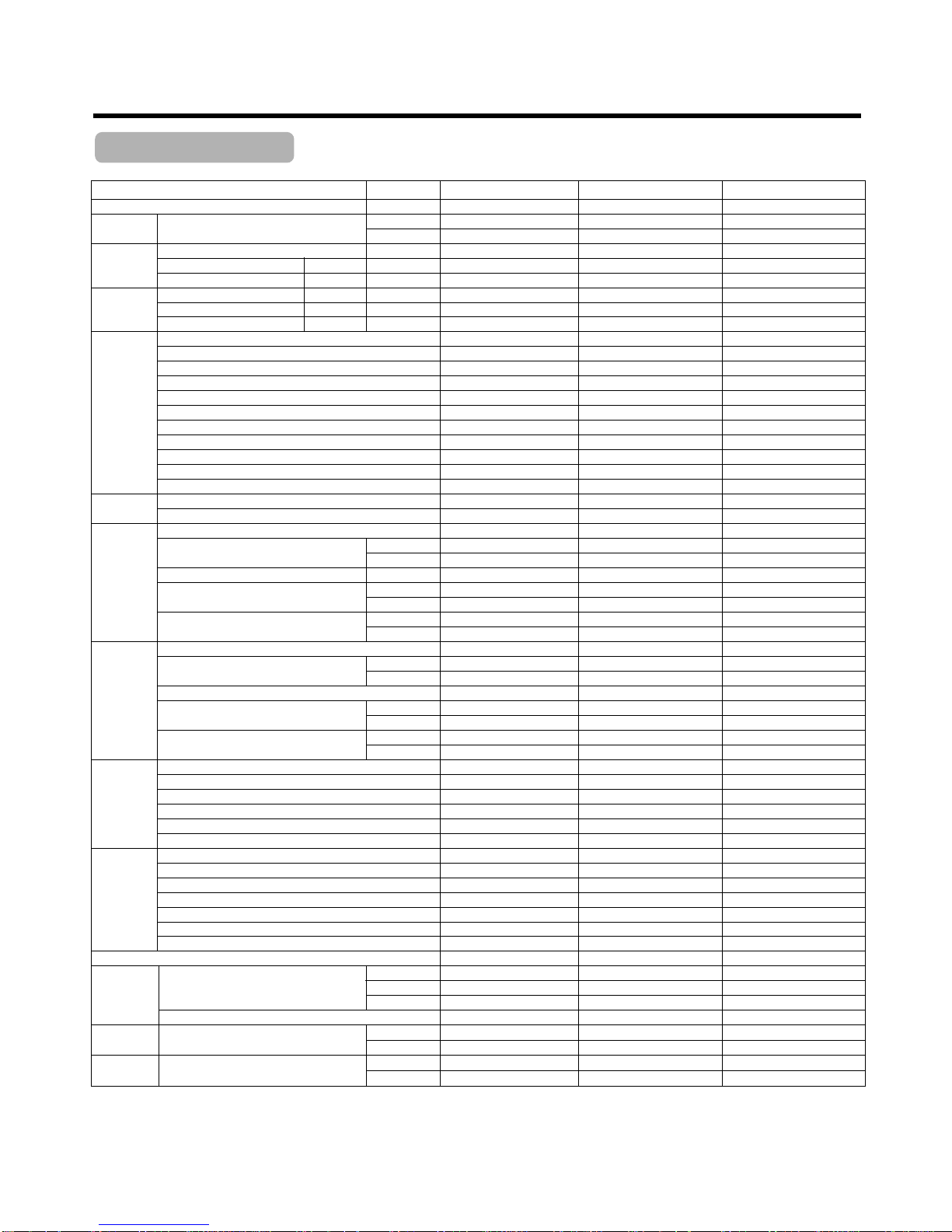

General Data

Table-1

Nominal ton (Ton) 3 4 5

Models LK-0329CH/AH LK-0429CH/AH LK-0529CH/AH

Capacity ARI Net Cooling Capacity (BTU/hr) 35,000 47,000 57,000

(Kcal/h) 8,821 11,845 14,364

Electrical Data

Voltage (V,PH) 208~230V,1PH 208~230V,1PH 208~230V,1PH

M.C.A(with standard motor)

Cooling (Amps) 29 31 48

Power Input Cooling (Watt) 3,740 4,350 6,000

Performance

Air Circulation

Nominal

CFM

CFM 1,050 1,590 1,750

SEER Cooling (BTU/hr.W) 10.0 11.0 10.0

Sound Rating Cooling dB(A) 8 8.4 8.4

Features LG Electronic Thermostat Option Option Option

Time Delay Safety Function

¥¥¥

Cooling Operation Mode

¥¥¥

Heating Operation Mode(with E/Heater)

¥¥¥

Soft Dry Operation - - -

Timer Setting (24-Hour on/off) - - -

Auto restart mode - - -

Humidifier function - - -

Test function - - -

Self-Diagnosis Function - - -

Filter type - - -

Compressor

Type

Scroll Scroll Scroll

Quantity 1 1 1

Outdoor Coil

Type

High efficiency High efficiency High efficiency

Tube size(O.D) (inch) 9/32 9/32 9/32

(mm) 7.00 7.00 7.00

Row/FPI 1R/18FPI 2R/18FPI 2R/18FPI

Lengh (inch) 55 1/8 55 1/8 55 1/8

(mm) 1,400 1,400 1,400

Face area (sq.ft) 10.72 10.72 10.72

(m2) 1.00 1.00 1.00

Indoor Coil

Type

High efficiency High efficiency High efficiency

Tube size(O.D) (inch) 3/8 3/8 3/8

(mm) 9.52 9.52 9.52

Row/FPI 2R/18FPI 3R/18FPI 3R/18FPI

Lengh (inch) 21 5/8 21 5/8 21 5/8

(mm) 550 550 550

Face area (sq.ft) 4.51 4.51 4.51

(m2) 0.42 0.42 0.42

Outdoor Fan

Type Propeller Propeller Propeller

No. Used/Diameter(in.) 1EA/22" 1EA/22" 1EA/22"

Drive Type Direct Direct Direct

CFM 3,500 3,500 3,500

No. Motor/Motor output(Hp) 1/0.33 1/0.33 1/0.33

Motor RPM 1,060 1,060 1,060

Indoor Fan

Type Centrifugal Blower Fan Centrifugal Blower Fan Centrifugal Blower Fan

No. Used 1EA 1EA 1EA

Diameter/Width(in.) 11"/11" 11"/11" 11"/11"

Drive Type/Motor Step Direct/3 Direct/3 Direct/3

No.motors 1EA 1EA 1EA

Motor output(standard/oversized) 0.5Hp/N.A 0.75Hp/N.A 0.75Hp/N.A

Motor rpm(Standard/oversized) 840N.A 1,020/N.A 1,090/N.A

Drain Connection Size(in.)

3/4" 3/4" 3/4"

Refrigerant

(kg) 1.7 2.2 2.3

Refrigerant Charge (lbs) 3.75 4.85 5.07

Type R-22 R-22 R-22

Refrigerant Control Capillary Tube Capillary Tube Capillary Tube

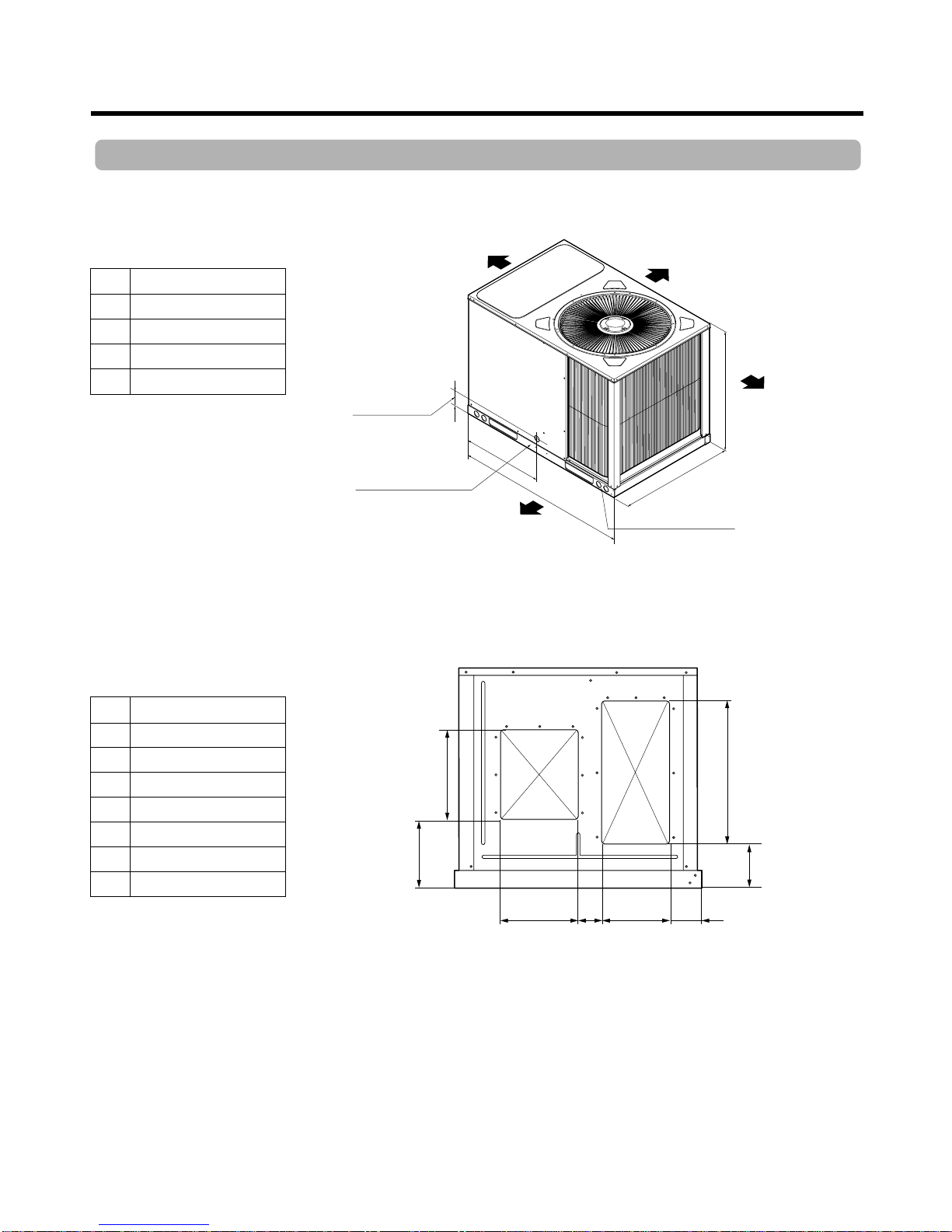

Dimensions

Indoor unit (WxHxD) (inch) 43 3/8*28 9/16*32 11/16 43 3/8*28 9/16*32 11/16 43 3/8*28 9/16*32 11/16

(mm) 1102*725*830 1102*725*830 1102*725*830

Weight Net (kg) 110 120 140

(lbs) 242.5 264.6 308.6