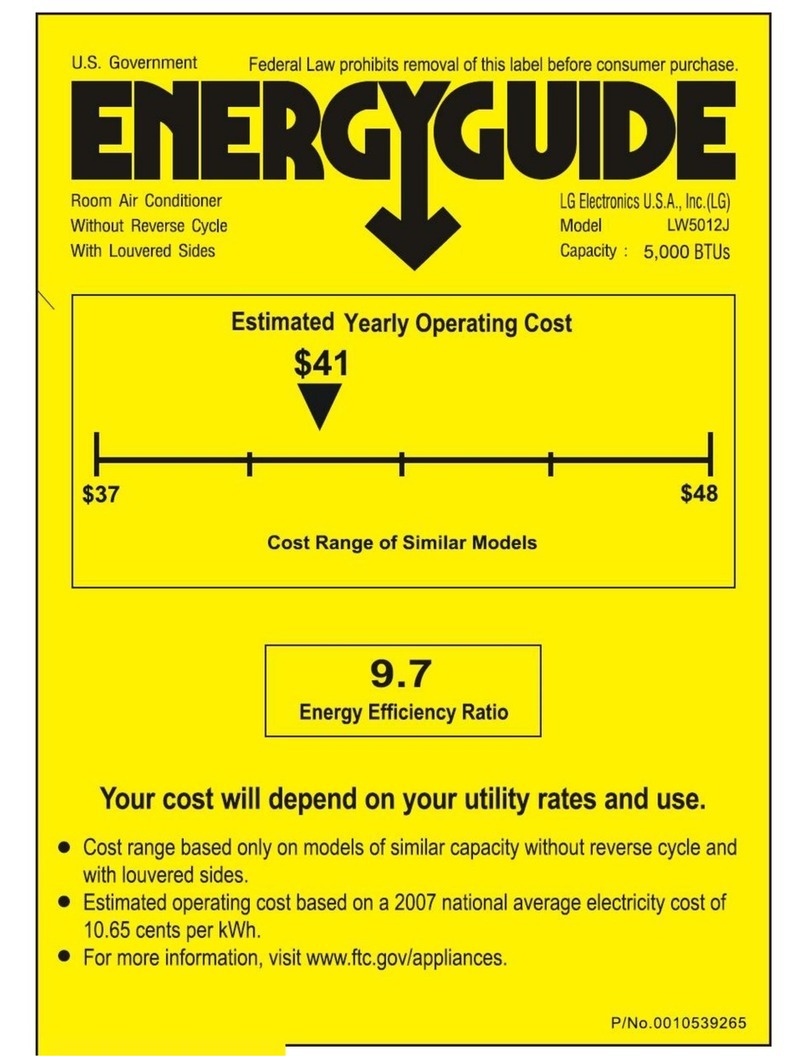

Installation check listConguration

System Design ApplicationsIntroduction

• System diagram

IDU

Purpose: Ams to provide generic oor heating/cooling operations.

Capable of setting up coil-based radiant heating and cooling system thanks to its simplied

installation structure - also enables heating and cooling by installing radiator/fan coil.

• Necessary conguration and feature

Dip s/w N/A

Keep default See if 2 and 3 are off

Remote controller Use the default one attached to indoor

unit

No installation required

Additional provision not available

Leaving water temperature

Set up by the remote controller Single temperature

control Control of leaving water temperature

• Dip s/w Setting

OFF

ON

1 23 45678

• System diagram

IDU

Remote room sensor

Purpose: Conguration for generic oor heating and cooling by utilizing indoor air temperature sensor.

Can be set up generally with radiator and oor heating coils, and product is operated based on

indoor air temperature setup.

• Necessary conguration and feature

Dip s/w N/A

Keep default Check if 2 and 3 are off

Remote controller Use the default one attached to indoor

unit No installation required

Leaving water temperature Set up by remote controller Single temperature

control Control of indoor air temperature

Air temperature sensor

Installation

Air temperature sensor is an option and needs

to be purchased and installed separately.

P/n : PQRSTA0

Installer setting

Remote controller needs to be set up separately.

• Dip s/w Setting

OFF

ON

1 23 45678

014 015

_

COMPREHENSIVE APPLICATION AND INSTALLATION MANUAL

LG Electronics

1. System 1 2. System 2