—3—

LP 12 0 C E M 1

12 34 5 6 7 8 9

Digits 1,2 - LG Packaged Terminal Air Conditioner Digit 6 - Product Type

Digits 3,4 - Unit Cooling Capacity C = Air Conditoner

07 = 7,000 Btu/h H = Heat Pump

09 = 9,000 Btu/h Digit 7- Electric Heat

12 = 12,000 Btu/h E = Electric Heater

15 = 15,000 Btu/h Digit 8 - D = Digital

M = Mechanical

Digit 9 - Electric Voltage

1 = 265V, 60Hz

None = 230V, 60Hz

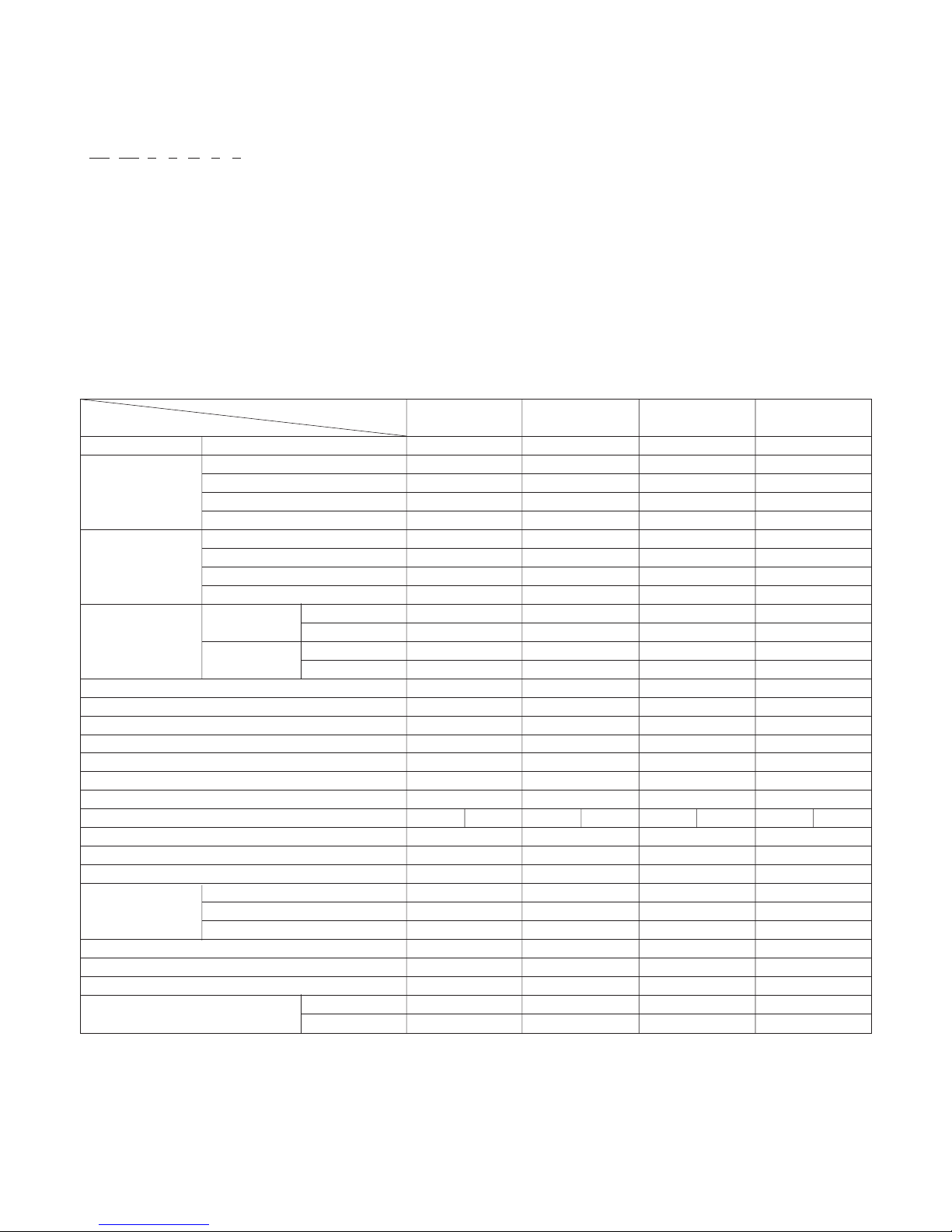

1.1 SPECIFICATIONS

MODELS

ITEMS

POWER SUPPLY

COOLING CAPACITY (Bru/h)

INPUT (W)

RUNNING CURRENT (A)

E.E.R. (Btu/h.W)

HEATING CAPACITY (Bru/h)

INPUT (W)

RUNNING CURRENT (A)

COP(W/W)

OPERATING COOLING INDOOR (°C)

TEMPERATURE OUTDOOR (°C)

HEATING INDOOR (°C)

OUTDOOR (°C)

REFRIGEANT(R-22) CHARGE(g)

EVAPORATOR

CONDENSER

FAN, INDOOR

FAN, OUTDOOR

FAN SPEEDS (FAN/COOLING/HEATING)

FAN MOTOR

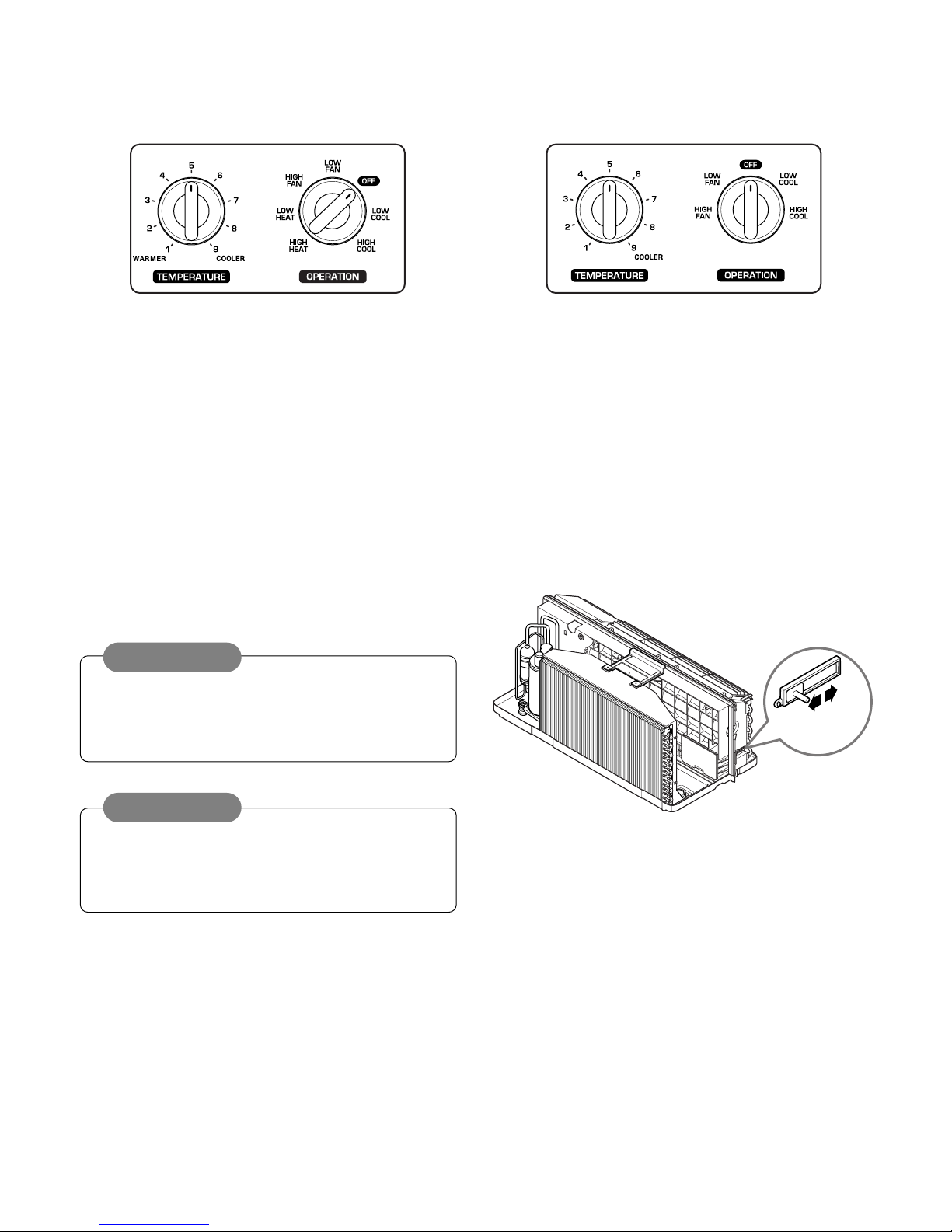

OPERATION CONTROL

ROOM TEMP. CONTROL

CONSTRUCTION

ELECTRIC HEATER

PROTECTOR COMPRESSOR

FAN MOTOR

ELECTRIC HEATER

POWER CORD

DRAIN SYSTEM

NETWEIGHT(lbs/Kg)

DIMENSION (W*H*D) (inch)

(mm)

LP090CED LP120CED LP150CED LP070HED

1Ø, 230/208V, 60Hz 1Ø, 230/208V, 60Hz 1Ø, 230/208V, 60Hz 1Ø, 230/208V, 60Hz

9,000/8,800 11,800/11,500 14,300/14,100 7,600/7,300

770/750 1,055/1,025 1,430/1,410 600/575

3.5/3.8 4.8/5.2 6.5/7.1 2.7/2.9

11.7/11.7 11.2/11.2 10.0/10.0 12.7/12.7

- - - 6,400/6,200

---535/520

- - - 2.4/2.6

- - - 3.5/3.5

26.7 (DB) 19.4(WB) 26.7 (DB) 19.4(WB) 26.7 (DB) 19.4(WB) 26.7 (DB) 19.4(WB)

35 (DB) 23.9(WB) 35 (DB) 23.9(WB) 35 (DB) 23.9(WB) 35 (DB) 23.9(WB)

21.1 (DB) 15.6(WB) 21.1 (DB) 15.6(WB) 21.1 (DB) 15.6(WB) 21.1 (DB) 15.6(WB)

8.3 (DB) 6.1(WB) 8.3 (DB) 6.1(WB) 8.3 (DB) 6.1(WB) 8.3 (DB) 6.1(WB)

790(27.9 OZ) 630(22.2 OZ) 735(25.9 OZ) 610(21.5 OZ)

2 ROE 10 STACKS 2 ROE 10 STACKS 2 ROE 10 STACKS 2 ROE 12 STACKS

2 ROE 14 STACKS 2 ROE 17 STACKS 2 ROE 17 STACKS 2 ROE 17 STACKS

Cross Flow Fan Cross Flow Fan Cross Flow Fan Cross Flow Fan

Axial Fan Axial Fan Axial Fan Axial Fan

2/2/2 2/2/2 2/2/2 2/2/2

4POLES 4POLES 4POLES 4POLES

MANUAL TYPE MANUAL TYPE MANUAL TYPE MANUAL TYPE

THERMISTOR THERMISTOR THERMISTOR THERMISTOR

SLID IN-OUT SLID IN-OUT SLID IN-OUT SLID IN-OUT

3.5KW, 230V 3.5KW, 230V 3.5KW, 230V 2.5KW, 230V

EXTERNAL OVERLOAD PROTECTOR EXTERNAL OVERLOAD PROTECTOR EXTERNAL OVERLOAD PROTECTOR EXTERNAL OVERLOAD PROTECTOR

INTERNAL THERMAL PROTECTOR INTERNAL THERMAL PROTECTOR INTERNAL THERMAL PROTECTOR INTERNAL THERMAL PROTECTOR

FUSE LINK, BIMETAL THERMOSTAT FUSE LINK, BIMETAL THERMOSTAT FUSE LINK, BIMETAL THERMOSTAT FUSE LINK, BIMETAL THERMOSTAT

1.6m(3 WIRE WITH GROUDING) 1.6m(3 WIRE WITH GROUDING) 1.6m(3 WIRE WITH GROUDING) 1.6m(3 WIRE WITH GROUDING)

SPLASHED BY FAN SLINGER SPLASHED BY FAN SLINGER SPLASHED BY FAN SLINGER SPLASHED BY FAN SLINGER

92/42.8 96/43.7 101/45.7 90/40.7

41 31/32*15 31/32*19 27/32 41 31/32*15 31/32*19 27/32 41 31/32*15 31/32*19 27/32 41 31/32*15 31/32*19 27/32

1066*406*505 1066*406*505 1066*406*505 1066*406*505