3

CONTENTS

1. SPECIFICATIONS ............................................................................................................... 4

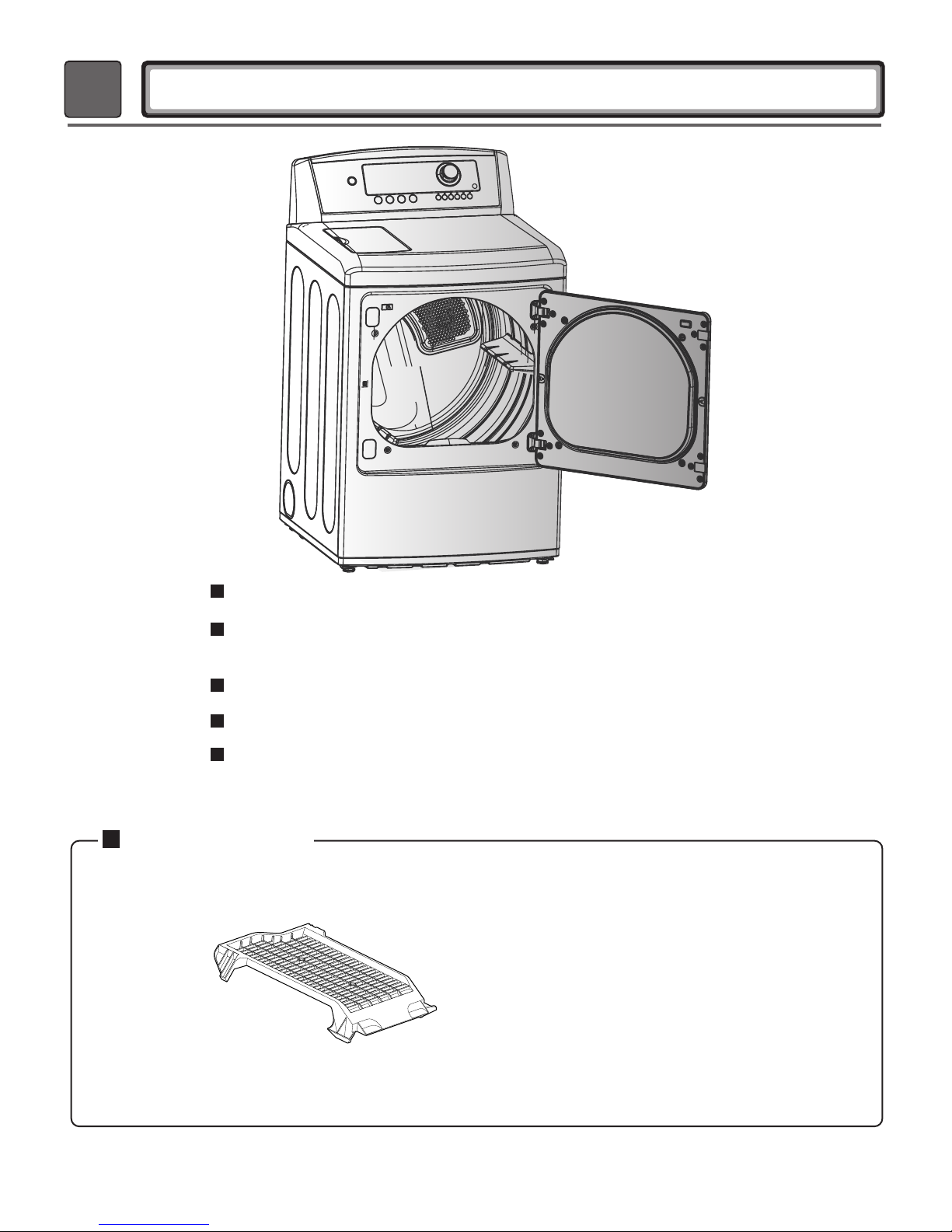

2. FEATURES AND BENEFITS ............................................................................................... 6

3. INSTALLATION INSTRUCTIONS ........................................................................................ 6

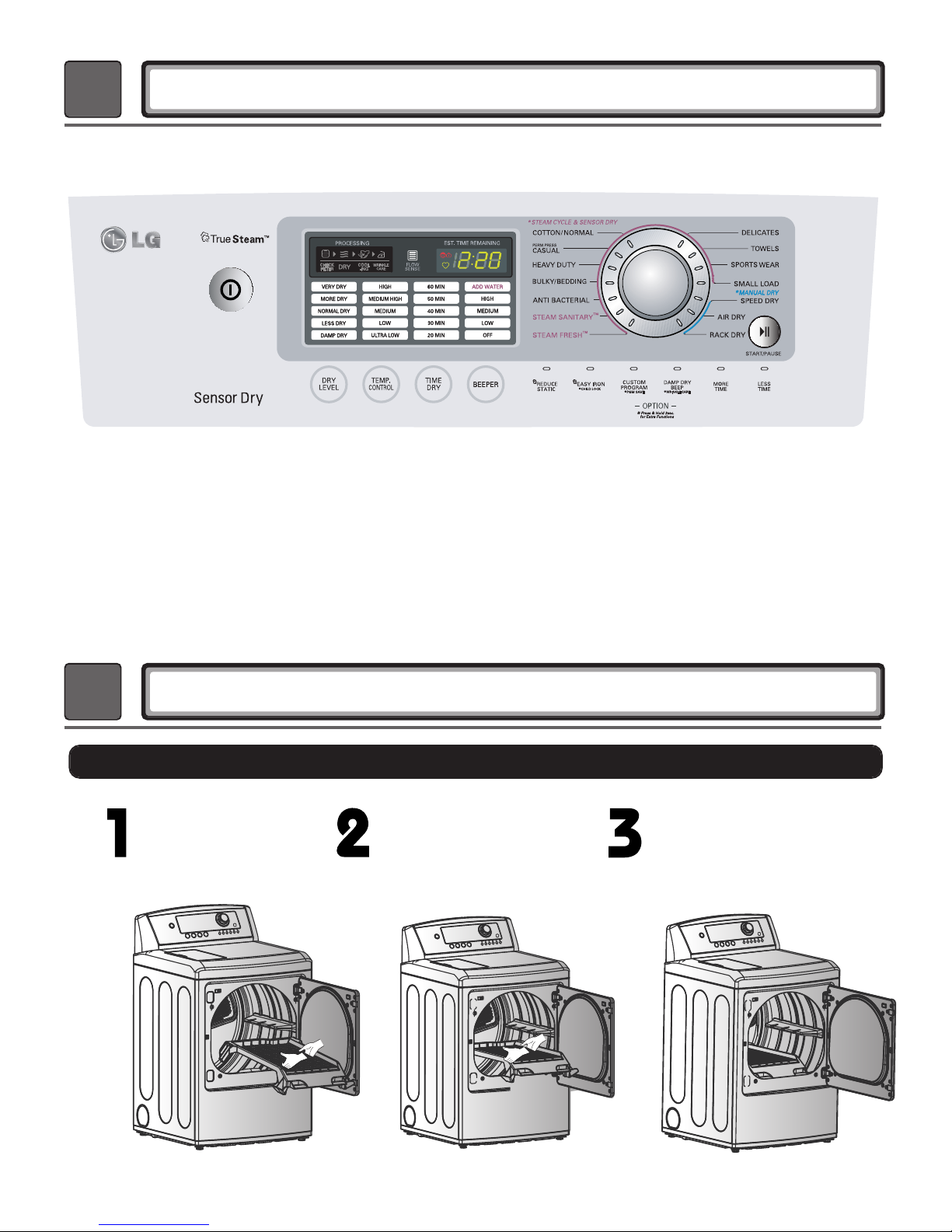

4. DRYER CYCLE PROCESS ................................................................................................ 10

5. COMPONENT TESTING INFORMATION ......................................................................... 11

6. MOTOR DIAGRAM AND SCHEMATIC ............................................................................. 14

7. WIRING DIAGRAM ............................................................................................................ 15

8. STEAM FUNCTION ............................................................................................................ 16

8-1. STEAM CYCLE GUIDE ............................................................................................ 16

8-2. TROUBLESHOOTING .............................................................................................. 17

8-3. DISPLAY FAULT/ERROR CODES ............................................................................18

9. FLOW SENSOR FUNCTION ............................................................................................. 19

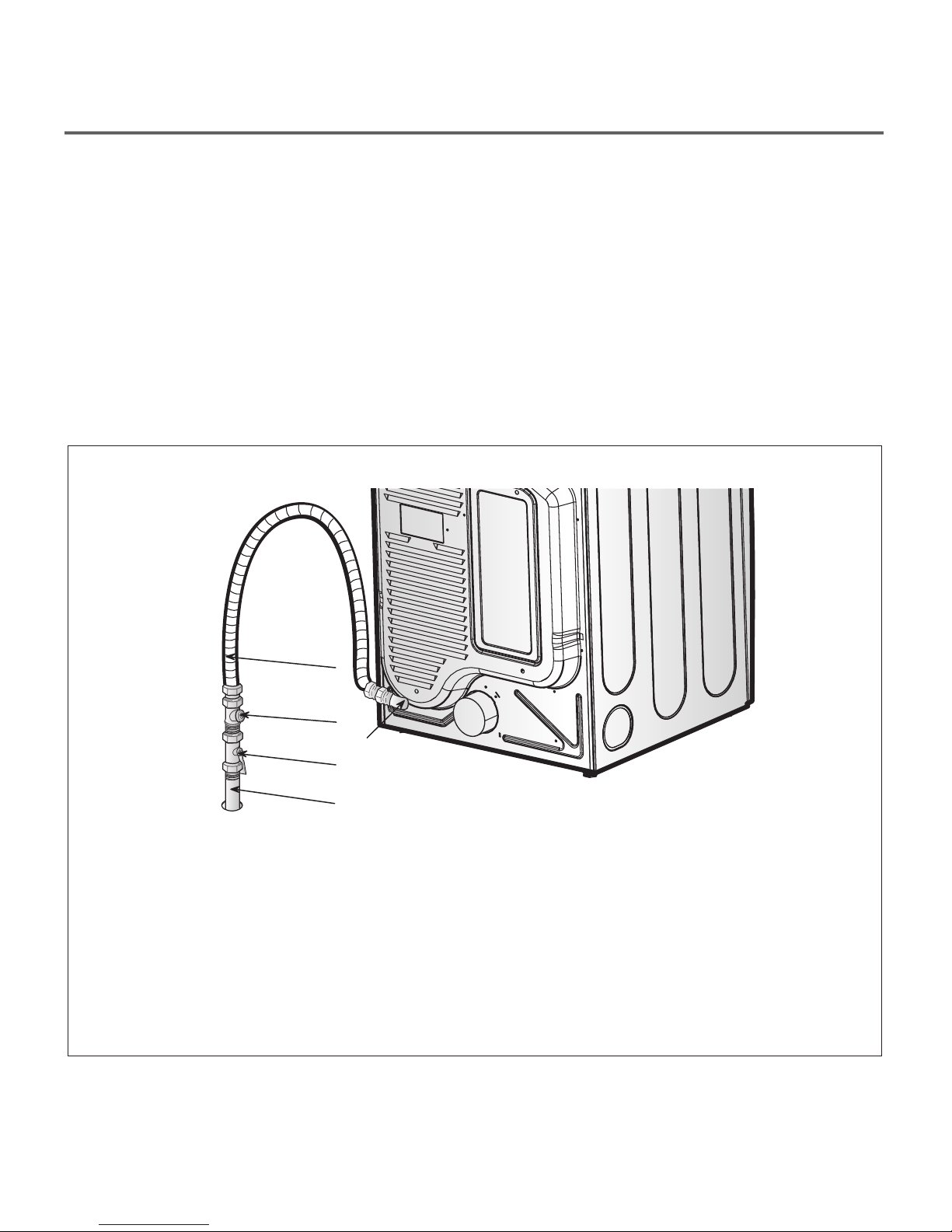

9-1. FLOW SENSOR ....................................................................................................... 19

9-2. INSTALLATION CHECK .......................................................................................... 20

9-3. TROUBLESHOOTING FOR FLOW SENSOR DRYER ............................................ 21

10. DIAGNOSTIC TEST ........................................................................................................ 22

10-1. TEST 1 120 VAC ELECTRICAL SUPPLY ............................................................. 23

10-2. TEST 2 THERMISTOR TEST - MEASURE WITH POWER OFF ......................... 26

10-3. TEST 3 MOTOR TEST ......................................................................................... 27

10-4. TEST 4 MOISTURE SENSOR .............................................................................. 28

10-5. TEST 5 DOOR SWITCH TEST ............................................................................. 29

10-6. TEST 6 HEATER SWITCH TEST - ELECTRIC TYPE .......................................... 30

10-7. TEST 7 GAS VALVE TEST - GAS TYPE .............................................................. 31

10-9. TEST 8 MOTOR ASSEMBLY, DC, PUMP ............................................................ 32

10-10. TEST 9 GENERATOR ASSEMBLY .................................................................... 33

11. CHANGE GAS SETTING (NATURAL GAS, PROPANE GAS) ....................................... 34

12. DISASSEMBLY INSTRUCTIONS .................................................................................... 36

13. EXPLODED VIEW ............................................................................................................ 46

13-1. CONTROL PANEL AND PLATE ASSEMBLY ......................................................... 46

13-2. GUIDE ASSEMBLY ................................................................................................. 47

13-3-1. CABINET AND DOOR ASSEMBLY: ELECTRIC TYPE ....................................... 48

13-3-2. CABINET AND DOOR ASSEMBLY: GAS TYPE ................................................. 49

13-4-1. DRUM AND MOTOR ASSEMBLY: ELECTRIC TYPE ......................................... 50

13-4-2. DRUM AND MOTOR ASSEMBLY: GAS TYPE ................................................... 51