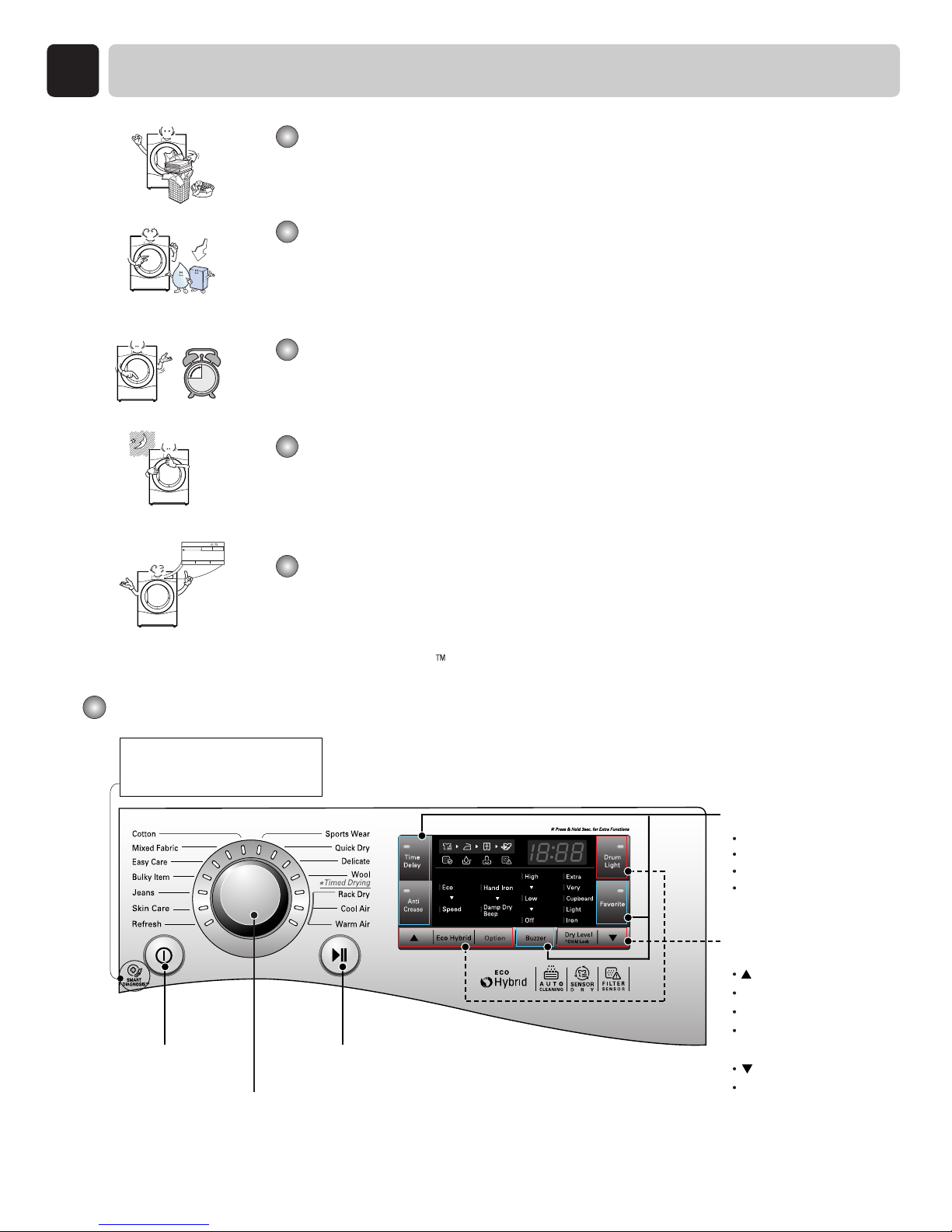

PROGRAM CYCLE

4

8

Cycle Selection Table

CAUTION

If the load is less than 1kg, please use the “Warm Air” Cycle in Timed Drying Cycle.

Wool items should be dried using the “Wool” Cycle and heat-sensitive fabrics including silk, underwear and

lingerie should be dried using the “Delicate” Cycle. Please comply with the recommended laundry load when

you select your desired Cycle- found on page 19. Otherwise, your clothes may be damaged.

Sensor Dry Cycle

Cycle Laundry Type Detail

Drying Level

Timed Drying Cycle

Extra

Very

Cupboard

Light

Iron

Iron

Iron

-

-

-

-

-

-

-

-

-

-

-

Cupboard

Cupboard

Very

Towels, dressing gowns and bed

linen

For thick and quilted fabrics

Terry towels, tea towels, towels

and bed linen

For thick and quilted fabrics that do not need to be

ironed

Bath towels, tea towels,

underwear and cotton socks

For fabrics that do not need to be ironed

Sheets, pillowcase and towels

For fabrics that do not need to be ironed

Bed linen, table linen, towels,

T-shirts, polo shirts and work

clothes

For fabrics that do need to be ironed

Mixed Fabric

Bed linen, table linen, tracksuits,

anoraks and blankets

For thick and quilted fabrics that do not need to be

ironed

Shirts and blouses

For fabrics that do not need to be ironed

Trousers, dressers, skirts and

blouses

For fabrics that do need to be ironed

Tumbles without heat

All fabrics that need refreshing

Cool Air

T-shirts, pillowcase, and towels

Skin Care

Shirts and blouses

Refresh

(Refer to the Note)

For cotton fabrics which do not need to be ironed

Odor removal of fabric

(For fabrics in need of odor removal)

Bath towels, bath robes,

dishcloth and quilted fabrics

made of acrylic

Warm Air Small Items & damp clothing

Everyday items suitable for heat drying

Silk, wool, delicate lingerie

Rack Dry Refresh clothes without tumble drying

Shirts, T-shirts, trousers,

under-wear and socks

For polyamide, acrylic, and polyester that do not

need to be ironed

Easy care

Shirts, T-shirts, under-wear,

anoraks and socks

For polyamide, acrylic, polyester that do need to be

ironed

Soccer kit and training wear

Sports Wear For polyester material

Jeans and colour fading

garments.

Jeans For jeans which do not need to be ironed

Silk, fine fabrics and lingerie

Delicate For fabrics that are heat-sensitive like synthetic

fabrics

Wool

Wool For wool fabrics

Bed clothes, sheets

Bulky Item For bulky items

Linen and towels, excluding

fabrics applied to delicate, sports

wear, bulky Item cycle.

For small loads of suitable fabrics with short drying

times

Quick Dry

Cotton

Note

When using the “Refresh” course, please spray cold or warm water on the fabric for a fresher

outcome. (The recommend amount is 20cc of water per shirt.)