5-7

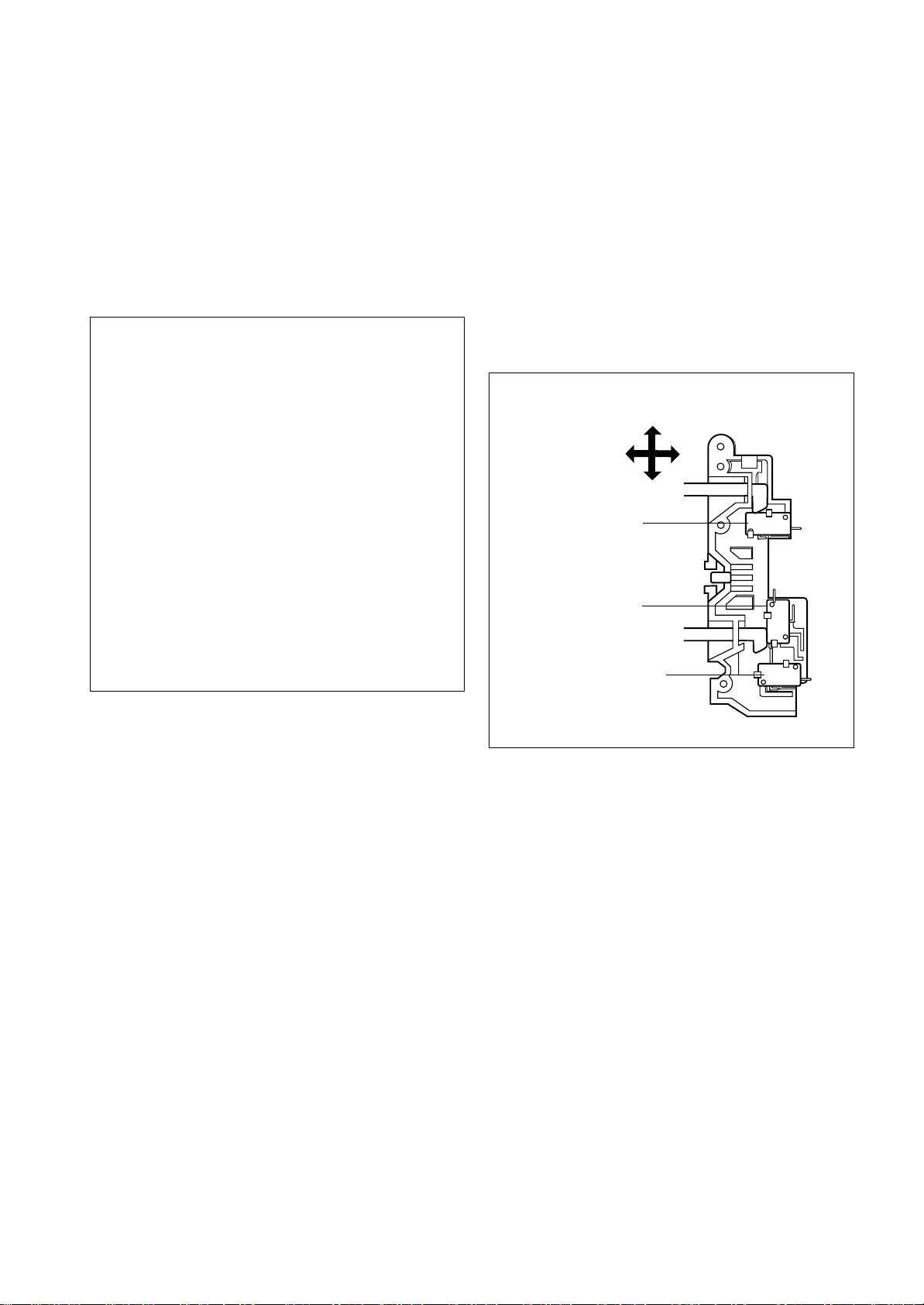

A. PRIMARY INTERLOCK SWITCH TEST

When the door button is slowly depressed with the

door closed, an audible "click" should be heard at the

same time or successively at intervals. When the but-

ton is slowly released, the latches should activate the

switches with an audible "click".

If the latches do not activate the switches when the

door is closed, the switches should be a adjusted in

accordance with adjustment procedure.

Disconnect the wire lead from the primary switch.

Connect the ohmmeter leads to the common (COM)

and normally open (NO) terminal of the switch. The

meter should indicate an open circuit in the door

open condition.

When the door is closed, the meter should indicate a

closed circuit.

When the primary switch operation is abnormal,

make the necessary adjustment or replace the switch

only with the same type of switch.

B. SECONDARY INTERLOCK SWITCH

TEST

Disconnect the wire lead from the secondary switch.

Connect the ohmmeter leads to the common (COM)

and normally open(NO) terminals of the switch. The

meter should indicate an open circuit in the door

open condition. When the door is closed, meter

should indicate a closed circuit. When the secondary

switch operation is abnormal, make the necessary

adjustment or replace the switch only with the same

type of switch.

C. MONITOR SWITCH TEST

Disconnect the wire lead from the monitor switch.

Connect the ohmmeter leads to the common (COM)

and normally close(NC) terminals of the switch. The

meter should indicate closed circuit in the door open

condition. When the door is closed, meter should

indicate an open circuit.

When the monitor switch operation is abnormal,

replace the same type of switch.

NOTE: After reparing the door or the interlock

system, it is necessary to do this continuity test

before operating the oven.

Interlock Continuity Test

WARNING: FOR CONTINUED PROTECTION AGAINST EXCESSIVE RADIATION

EMISSION, REPLACE ONLY WITH IDENTICAL REPLACEMENT PARTS.

TYPE NO. SZM-V16-FA-63 OR VP-533A- OF FOR PRIMARY SWITCH

TYPE NO. SZM-V16-FA-62 OR VP-532A- OF FOR MONITOR SWITCH

TYPE NO. SZM-V01-FA-33 OR VP-133A- OF FOR SECONDARY SWITCH

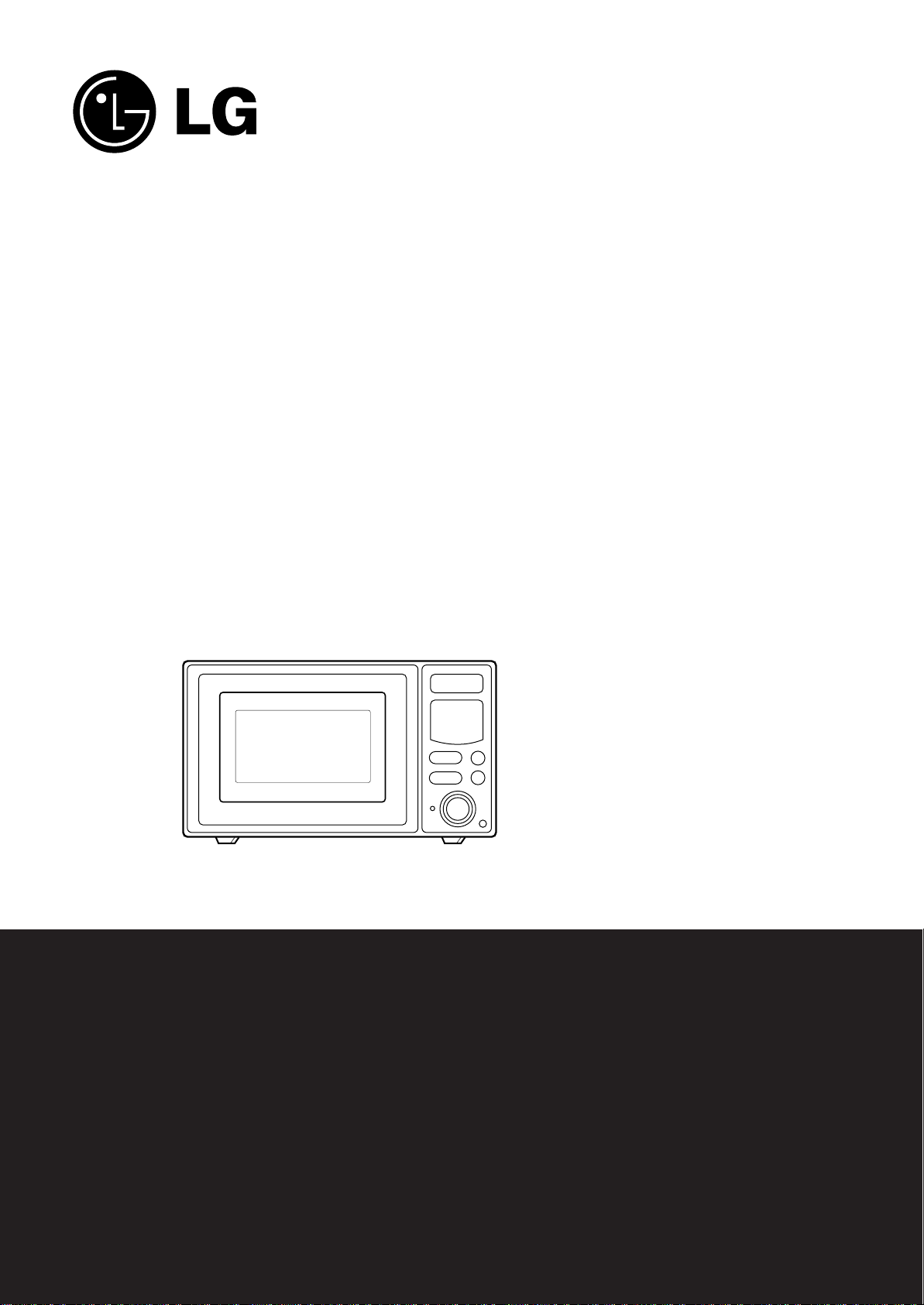

COMPONENTS TEST PROCEDURE RESULTS

SWITCHES

(Wire leads removed.)

Check for continuity of the switch

with an Multi-meter

NOTE: After checking for the continuity of switches, make sure that they

are correctly connected.

Primary

Switch

Monitor

Switch

Secondary

Switch

Door Door

open close