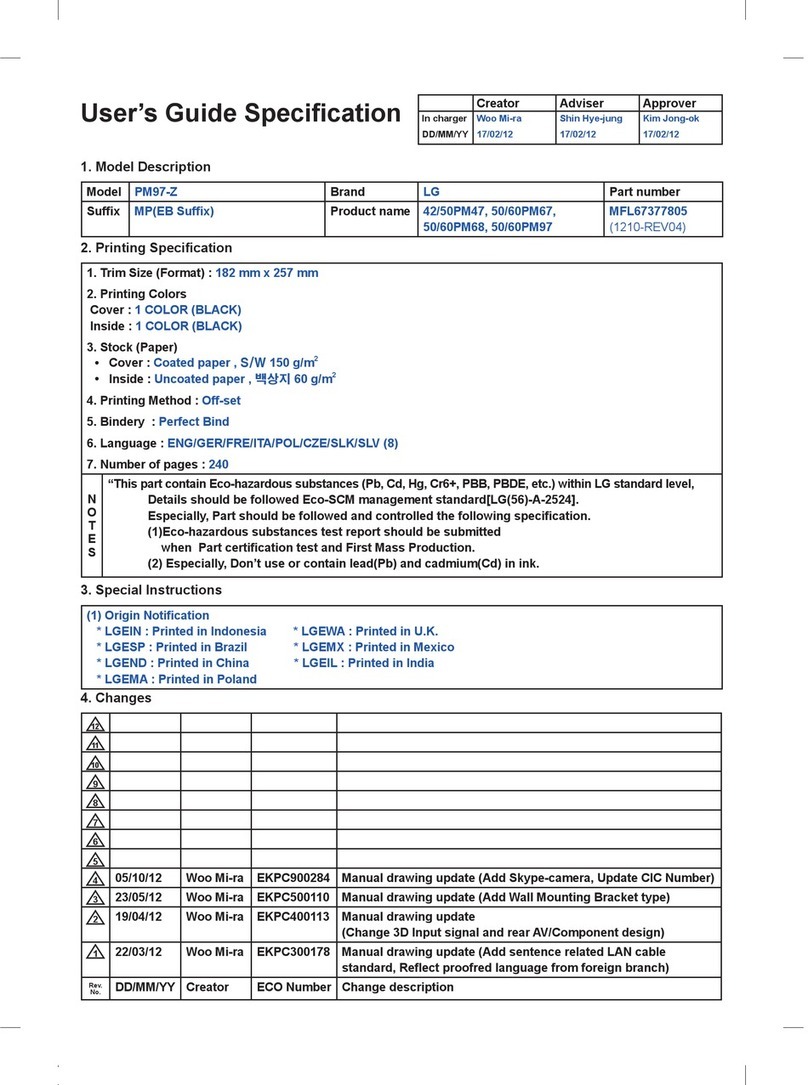

7

Plasma Display Panel Troubleshooting - 2007

Switch Mode Power Supply (SMPS) Voltages

•VS196v used to drive the Horizontal Grid Voltage, Y SUS, and Z SUS. Measured from pins 8, 9,

and 10 of connector P805 to chassis ground. Adjusted at VR951

•VA

60v used to drive the Vertical Grid Voltage, X Boards and in the IPM Circuits to develop Y and Z

Drive waveforms. Measured from pins 1 and 2 of connector P805 to chassis ground. Adjusted at

VR901

•5v.DC

Used to develop bias voltages for the circuits on the Y SUS, Z SUS, X, and Control Boards.

Measured from pins 1 and 2 of connector P804 to chassis ground.

•3.3v

. Standby voltage applied to the Analog, and Digital Boards to Bias the Signal and Control

circuits. Measured at connector P803 at pins 1 and 2. to chassis ground. Adjusted at VR221.

•19v

Applied to the Analog Board and used for the Audio Output Supply, present in standby.

Measured at P802 pins 1 and 2 to chassis ground.

•12v

Used for supplying low voltage regulators on the Digital and Analog Boards, present in standby.

Measured at P803 pins 9 and 10 to chassis ground.

•6v

Applied to the Digital Board used for the signal processing circuits present in standby. Measured

at P803 pins 5 and 6 to chassis ground.

•S5v

Standby 5 volts at P800 pin 3 applied to the Digital Board.

•VS-ON

Switched 5 volts at P800 pin 5 present after power up to switch on the VA, VS, and 5V on

the Power Board from the Digital Board.

•5v-DSwitched 5v used to bring the Power Supply out of Deep Sleep Mode.

•5V-M

Needed to turn on the 5V-DC Supply.

Troubleshooting