- 6 - LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Only or training and service purposes

ADJUSTMENT INSTRUCTION

1. Application Obj ct

These instructions are applied all o the 50” PLASMA TV,

PE81A Chassis.

2. Not

(1) Because this is not a hot chassis, it is not necessary to use

an isolation trans ormer. However, the use o isolation

trans ormer will help protect test instrument.

(2) Adjustment must be done in the correct order.

(3) The adjustment must be per ormed in the circumstance o

25±5°C o temperature and 65±10% o relative humidity i

there is no speci ic designation.

(4) The input voltage o the receiver must keep 100-240V~,

50/60Hz.

(5) The receiver must be operated or about 5 minutes prior to

the adjustment.

OA ter RGB Full white HEAT-RUN Mode, the receiver must

be operated prior to adjustment.

OEnter into HEAT-RUN MODE

1) Press the POWER ON KEY on R/C or adjustment.

2) OSD display and screen display PATTERN MODE.

* Set is activated HEAT-RUN without signal generator in

this mode.

* Single color pattern(RED/BLUE/GREEN) o HEAT-RUN

mode uses to check PANEL.

3.

ADC Calibration

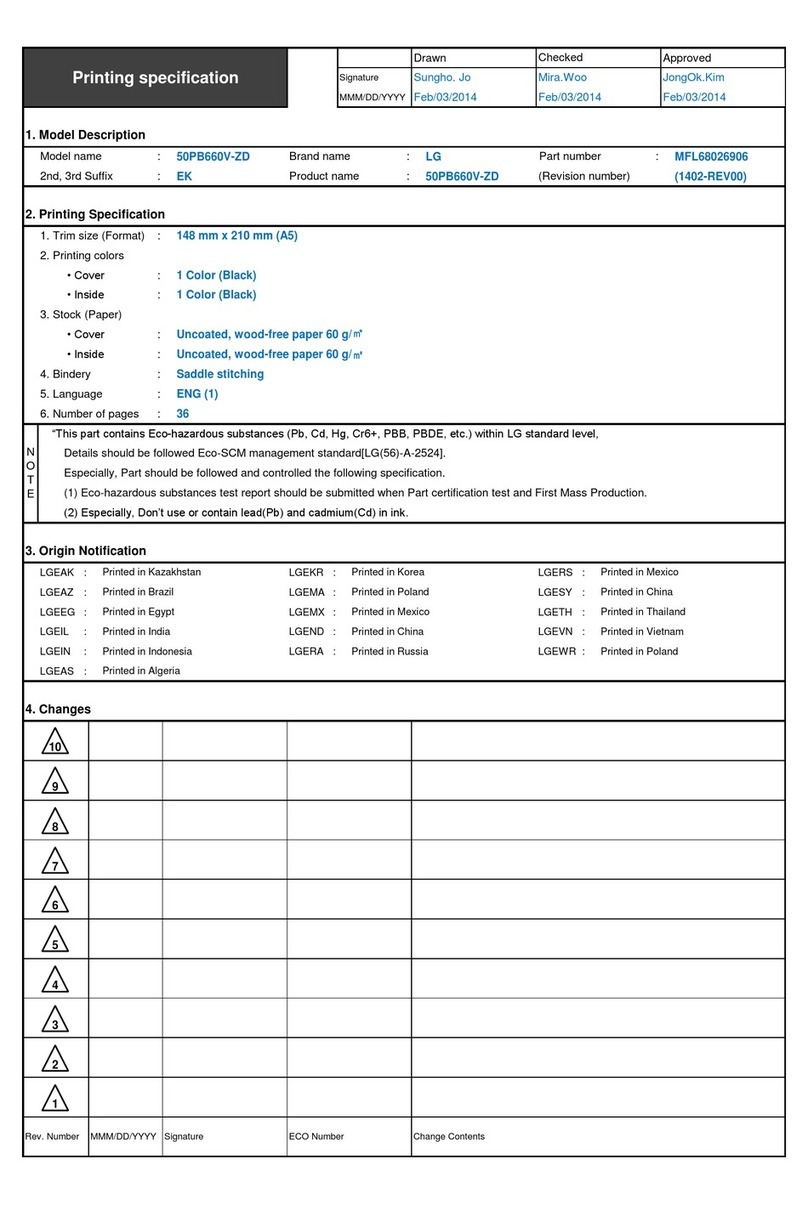

V Auto adjustment Map(RS-232C)

- Baud : 115200bps, RS232 Host : PC, Echo : none.

4. Adjustm nt of AV(CVBS)

4-1.

Standard Equipm nt

: 802F Pattern Generatorr. Master Pattern Generator(MSPG-

925, etc) or same product.

4-2. R quir d Equipm nt

O Remote controller or adjustment.

O MSPG-925FS Pattern Generator. (Which has Video Signal:

7 Color Bar Pattern shown in Fig.1)

-> Model: 202 / Pattern: 65 EC and FC model use PAL-

BGDHI(composite signal)

(1) Input the Video Signal: 7 Color Bar signal into AV3.

(2) Set the PSM to Dynamic mode in the Picture menu.

(3) Press IN-START key on R/C or adjustment.

(4) Press the G(Vol. +) key to operate the set, then it becomes

automatically.

5. Adjustm nt of Compon nt

5-1.

Standard Equipm nt

: 802F Pattern Generatorr. Master Pattern Generator(MSPG-

925, etc) or same product.

5-2. R quir d Equipm nt

O Remote controller or adjustment.

O MSPG-925FS Pattern Generator. (Which has Video Signal:

7 Color Bar Pattern shown in Fig.2)

-> Model: 215 / Pattern: 65 EC and FC model use PAL-

BGDHI(composite signal)

(1) Input the Component 720p/50Hz 7 color Bar Pattern(MSPG-

925FS model : 215, Pattern : 65) signal into Component.

(2) Set the PSM to Dynamic mode in the Picture menu.

(3) Press IN-START key on R/C or adjustment.

(4) Press the G(Vol. +) key to operate the set, then it becomes

automatically.

(5) Auto-RGB OK means the adjustment is completed.

* Using ‘power on’ button o the control R/C, power on TV.

I you turn on a still screen more than 20 minutes, (Especially

digital pattern, cross hatch pattern) a ter image may be occur in

the black level part o the screen.

ADC adjust

Data Read

De ault Write

Enter

Adjust Mode

ADC adjust

ADC Parameter

Digital Data

ADC Parameter

(Average)

Adjustment

Con irmation

Adjust Mode In

Adjust Mode O

NO Item Remark

CMD1 CMD2

Data 0

A

A

A

A

A

A

A

D

D

D

D

D

D

D

0

0

0

0

9

0

0

1

2

3

4

9

0

9

Trans er 18Byte

(Input resolution Data)

To check ADC Adjusment

on Assembly line

When transger the ‘Mode

In’, Carry the command.

MSPG925FS

Component RGB-PCAVADC

Model : 3

(1024*768 60Hz)

Pattern : 65

7 Color Bar

Model:215(720P)

Pattern : 65

* 720P/50Hz

7 Color Bar

PAL

INPUT SELECT AV3

Model : 202

(PAL-BGDHI)

Pattern : 65

* PAL 7 Color Bar

(Fig.1) 7 color Bar signal

(Fig.2) 7 color Bar signal