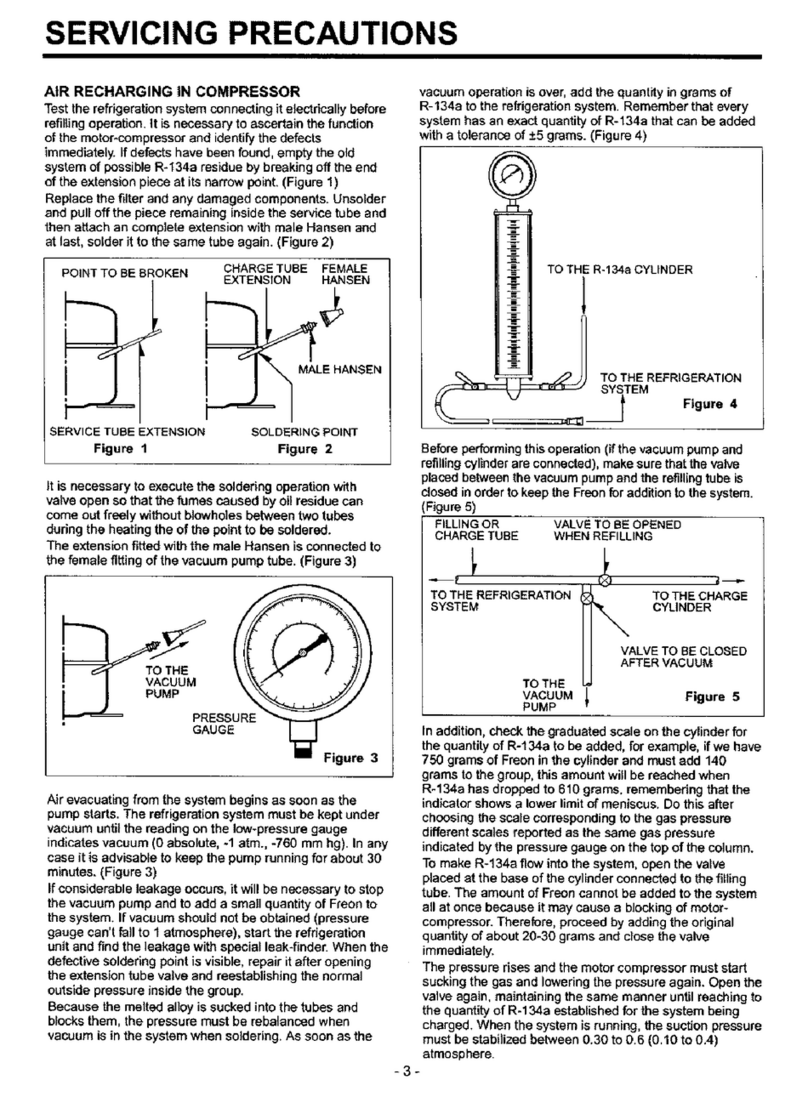

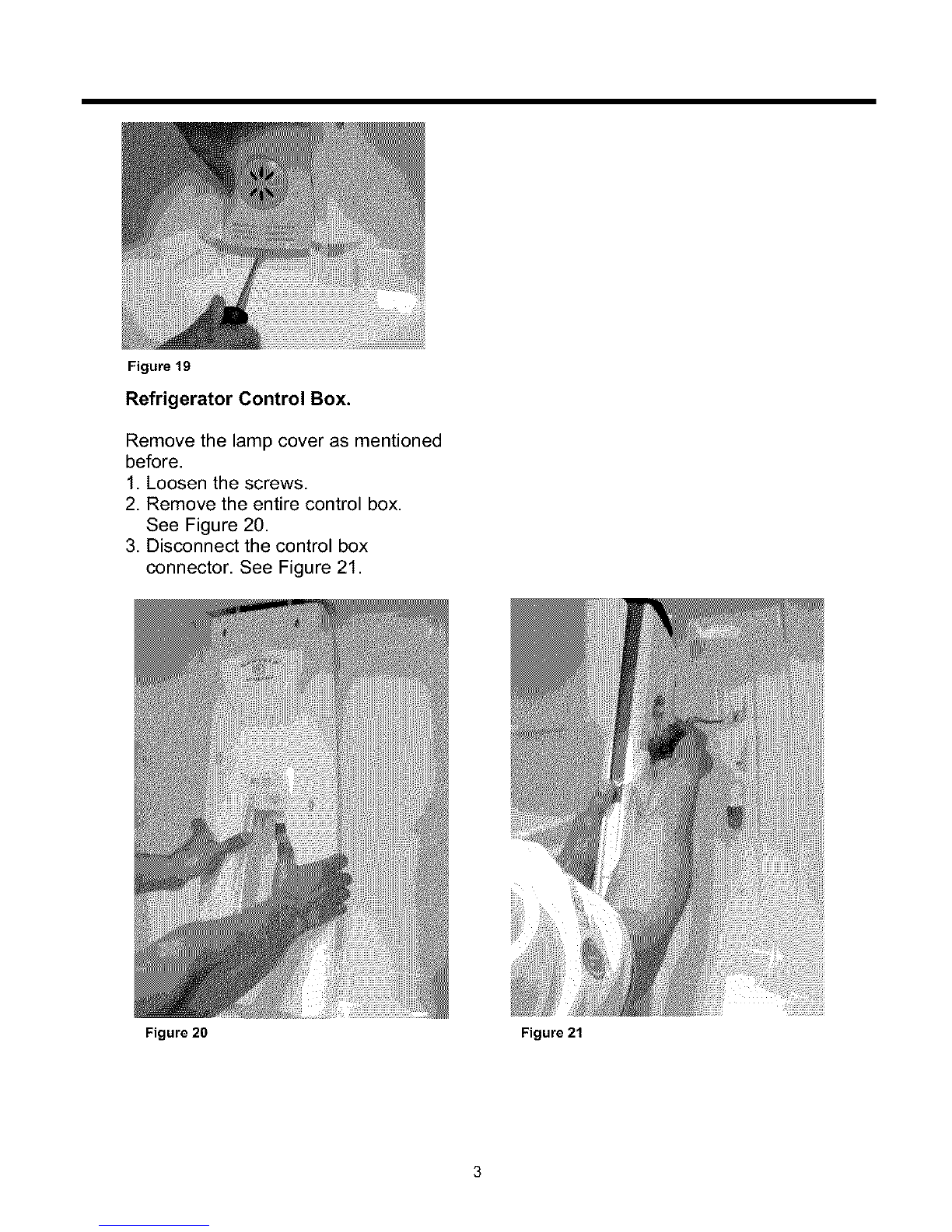

Service Precautions

Refrigerant Recharging

Test the compressor's operation before

recharging the refrigerant; this is very

important to detect failures and to

ensure the proper motor running, and

to identify failures immediately. If

failure has been detected, clean the

system from any other possible

R-134a residues by breaking the final

part of the compressor's service pipe

at it's thinnest part as shown in Fig. #1.

Replace the filter and any other part

that could be deteriorated. Unweld

and pull out the service pipe,

then place a new pipe extension with a

Hansen male connector and solder

the new pipe. See Fig. #2

POINTTO BE

BROKEN CHARGETUBE

EX?ENSiON

MALEHANiSEN

SERVICETUNEEXTENSION SOLDNRFNGPOINT

Figure 1i Fig;ute2

It is necessary to open the valve

when soldering to allow the gases to

escape without forcing the molten

solder out of the joint. The extension

with the male Hansen connector

should be connected to a female type

connector to the vacuum pump's pipe.

See Fig. #3

System air evacuation starts as soon

as the pump begins to run. The

system must be kept under vacuum

until the low pressure gauge shows

0(absolute or -1 atm, -760 mm Hg.) It

is not recommend to run the vacuum

pump for more than 30 minutes. See

Figure 3.

In case there is a large leak and the

vacuum operation must stop,

you must add a small amount of

refrigerant to the system and check

with an electronic leak detector. If a

soldering failure is detected, open the

valve before soldering to equalize the

pressure and keep solder from being

blown out of the joint or sucked into

the piping.

As soon as the repair is completed,

charge the correct amount of

refrigerant into the system.

Remember that each system requires

a specific amount of refrigerant with a

tolerance of +5 grams. See Figure 4.

TO THE b_ 134_ CYLliH_R

_3ySTE_ I_igur_ " 4

Before performing this operation (if

the vacuum pump and charging

cylinder are still attached to the

system) be sure the valve between

the pump and the cylinder is closed to