WARNINGS AND PRECAUTIONS FOR SAFETY ................................................................................................................ 3

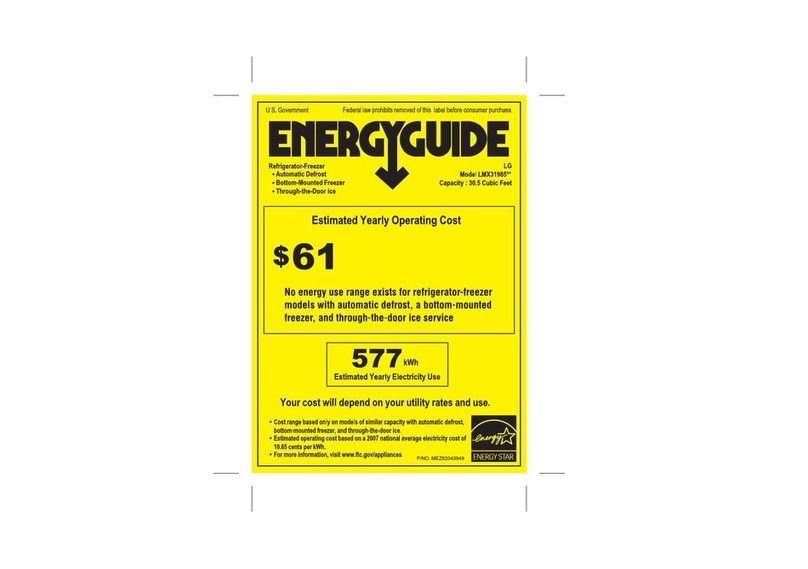

SPECIFICATIONS................................................................................................................................................................... 4

PARTS IDENTIFICATION ....................................................................................................................................................... 8

HOW TO INSTALL THE REFRIGERATOR .......................................................................................................................... 12

HOW TO ADJUST DOOR HEIGHT.................................................................................................................................... 12

FILTER ............................................................................................................................................................................... 13

HOW TO CONTROL THE ICEMAKER WATER SUPPLY.................................................................................................. 14

MICOM FUNCTION .............................................................................................................................................................. 16

EXPLANATION OF MICOM CIRCUIT .................................................................................................................................. 30

EXPLANATION OF PWB CIRCUIT .....................................................................................................................................30

PWB PARTS DIAGRAM AND LIST.....................................................................................................................................49

PWB CIRCUIT DIAGRAM ...................................................................................................................................................61

OPERATION PRINCIPLE AND REPAIR METHOD OF ICEMAKER ................................................................................... 65

OPERATION PRINCIPLE................................................................................................................................................... 65

CONTROL METHOD ACCORDING TO FUNCTIONS....................................................................................................... 66

DEFECT DIAGNOSIS FUNCTION..................................................................................................................................... 68

CIRCUIT................................................................................................................................................................................ 69

TROUBLE DIAGNOSIS........................................................................................................................................................ 72

TROUBLESHOOTING ....................................................................................................................................................... 72

FAULTS .............................................................................................................................................................................. 82

COOLING CYCLE HEAVY REPAIR ................................................................................................................................... 99

HOW TO DEAL WITH CLAIMS........................................................................................................................................ 106

HOW TO DISASSEMBLE AND ASSEMBLE ..................................................................................................................... 111

DOOR ............................................................................................................................................................................... 111

HANDLE ........................................................................................................................................................................... 112

FAN SHROUD GRILLE .................................................................................................................................................... 113

ICEMAKER ASSEMBLY ................................................................................................................................................... 113

DISPENSER ..................................................................................................................................................................... 114

TV-RADIO ............................................................................................................................................................................115

EXPLODED VIEW .............................................................................................................................................................. 121

REPLACEMENT PARTS LIST ........................................................................................................................................... 134

CONTENTS

- 2 -