CONTENTS

SAFETY PRECAUTIONS

Please read the following instructions before

servicing your refrigerator.

1. Check the refrigerator for current leakage.

2. To prevent electric shock, unplug before

servicing.

3. Always check line voltage and amperage.

4. Use standard electrical components.

5. Don't touch metal products in the freezer with

wet hands. This may cause frost bite.

6. Prevent water from spiling on to electric

elements or the machine parts.

7. Before tilting the refrigerator, remove all

materials from on or in the refrigerator.

8. When servicing the evaporator, wear gloves to

prevent injuries from the sharp evaporator fins.

9. Service on the refrigerator should be performed

by a qualified technician. Sealed system repair

must be performed by a CFC certified technician.

WARNINGS AND SAFETY PRECAUTIONS …………………………………………….........… 2

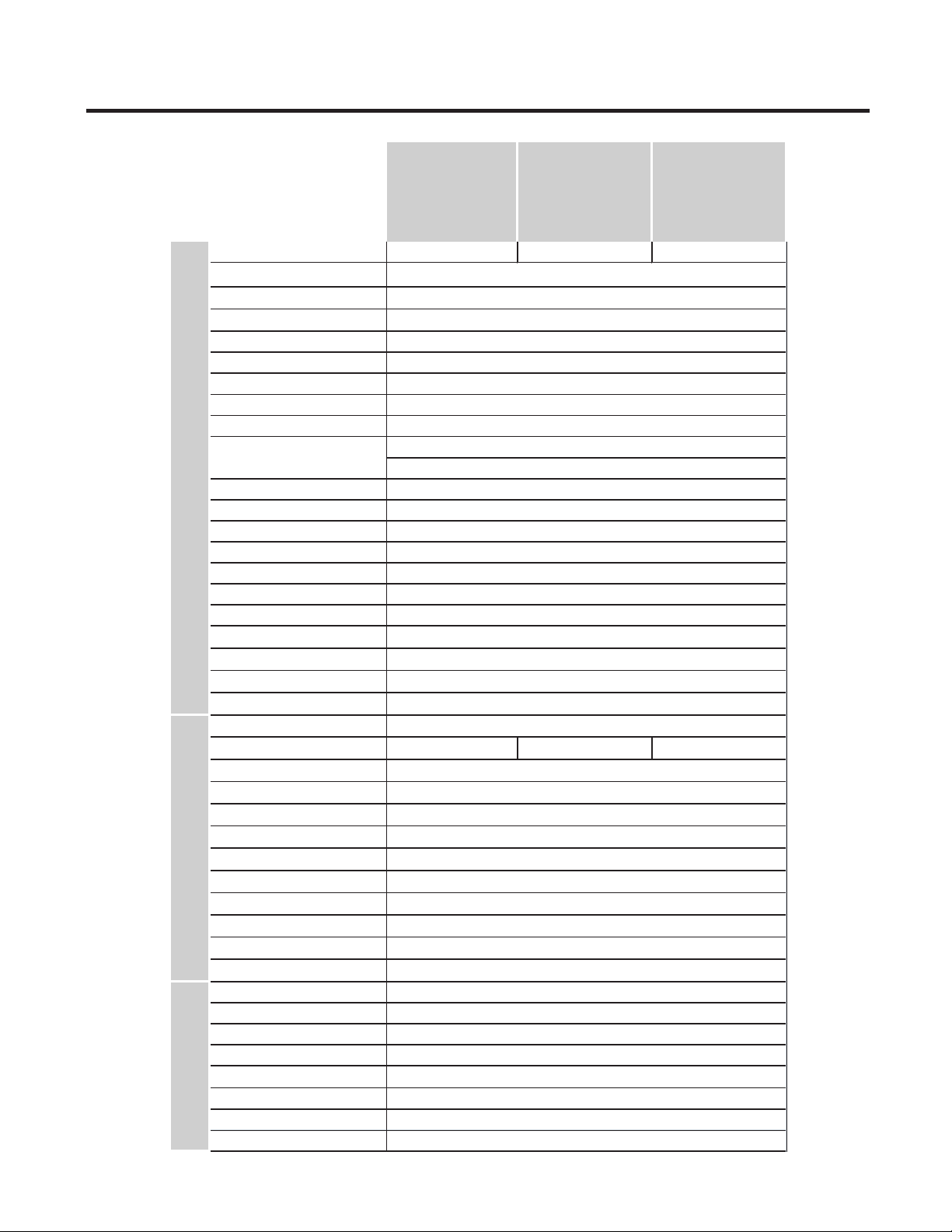

1. SPECIFICATIONS ………………………………………………………………………..…...…. 3

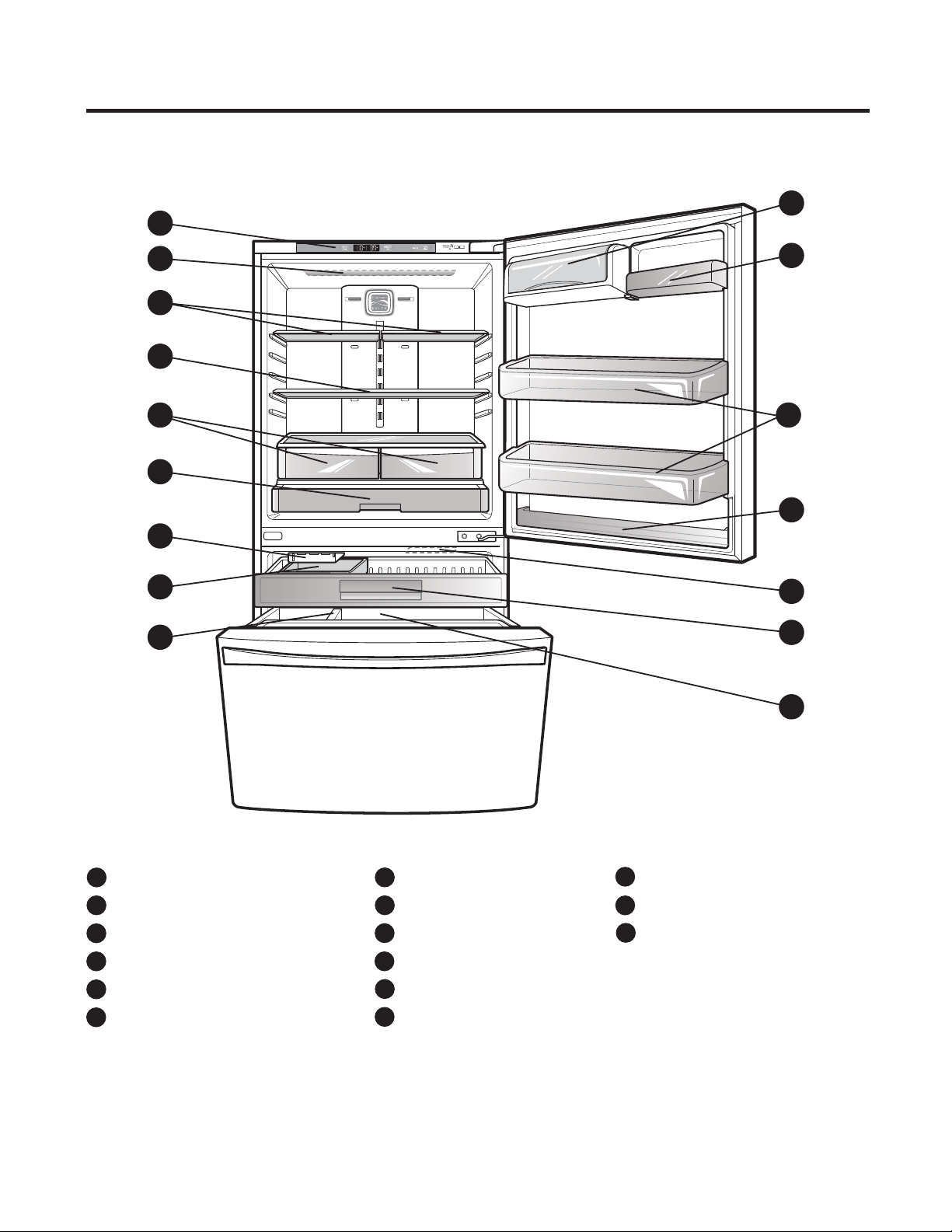

2. PARTS IDENTIFICATION …………………………………………………………………......... 4

3. DISASSEMBLY ………………………………………………………………………………….... 5

4. COMPRESSOR ELECTRICAL …………………………………………………………….…… 10

5. CIRCUIT DIAGRAM ……………………………………………………………………………… 13

6. PCB PICTURE ……………………………………………………………………………………. 14

7. TROUBLESHOOTING WITH ERROR DISPLAY …………………………………………...... 15

8. TROUBLESHOOTING WITHOUT ERROR DISPLAY ……………………………………….. 23

9. REFERENCE …………………………………………………………………………………....... 28

10. COMPONENT TESTING INFORMATION ………………………………………………........ 32

11. COMPRESSOR TROUBLESHOOTING …………………………………………………….... 37

12. ICE MAKER AND DISPENSER ……………………………………………………………...... 49

13. DESCRIPTION OF FUNCTION & CIRCUIT OF MICOM ………………………………….... 53

14. EXPLODED VIEW ……………………………………………………………………………..... 58

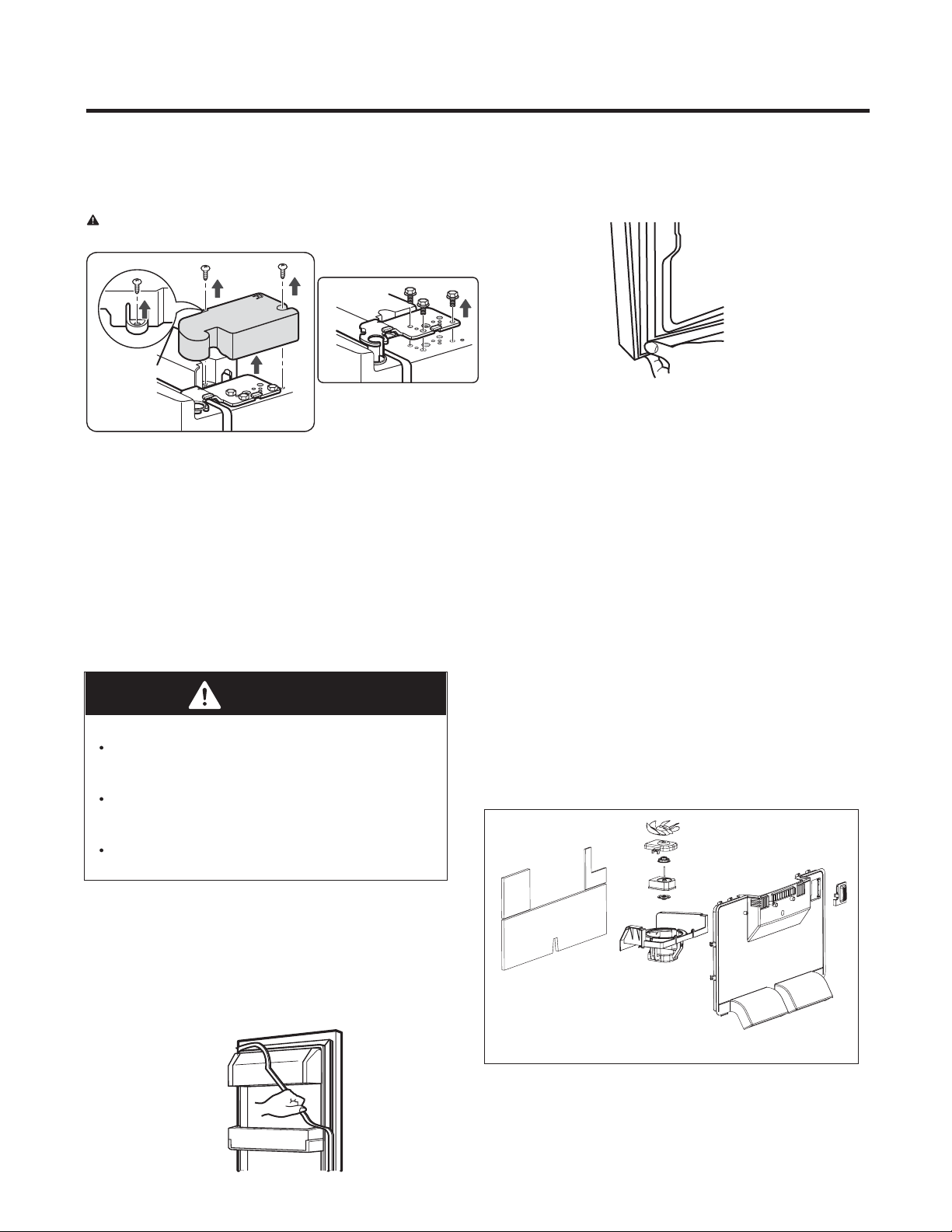

3-1 Removing and replacing refrigerator door …………………………………............... 5

3-2 Door ………………………………………………………………………………………. 5

3-3 Door Alignment ………………………………………………………………………….. 5

3-4 Fan and fan motor (Evaporator) ……………………………………………………..... 5

3-5 Defrost Control Assembly ………………………………………………………….....… 6

3-6 Lamp ……………………………………………………………………………………… 6

3-7 MultiDuct …………………………………………………………………………………. 6

3-8 Main PWB …………………………………………………………………………...…... 6

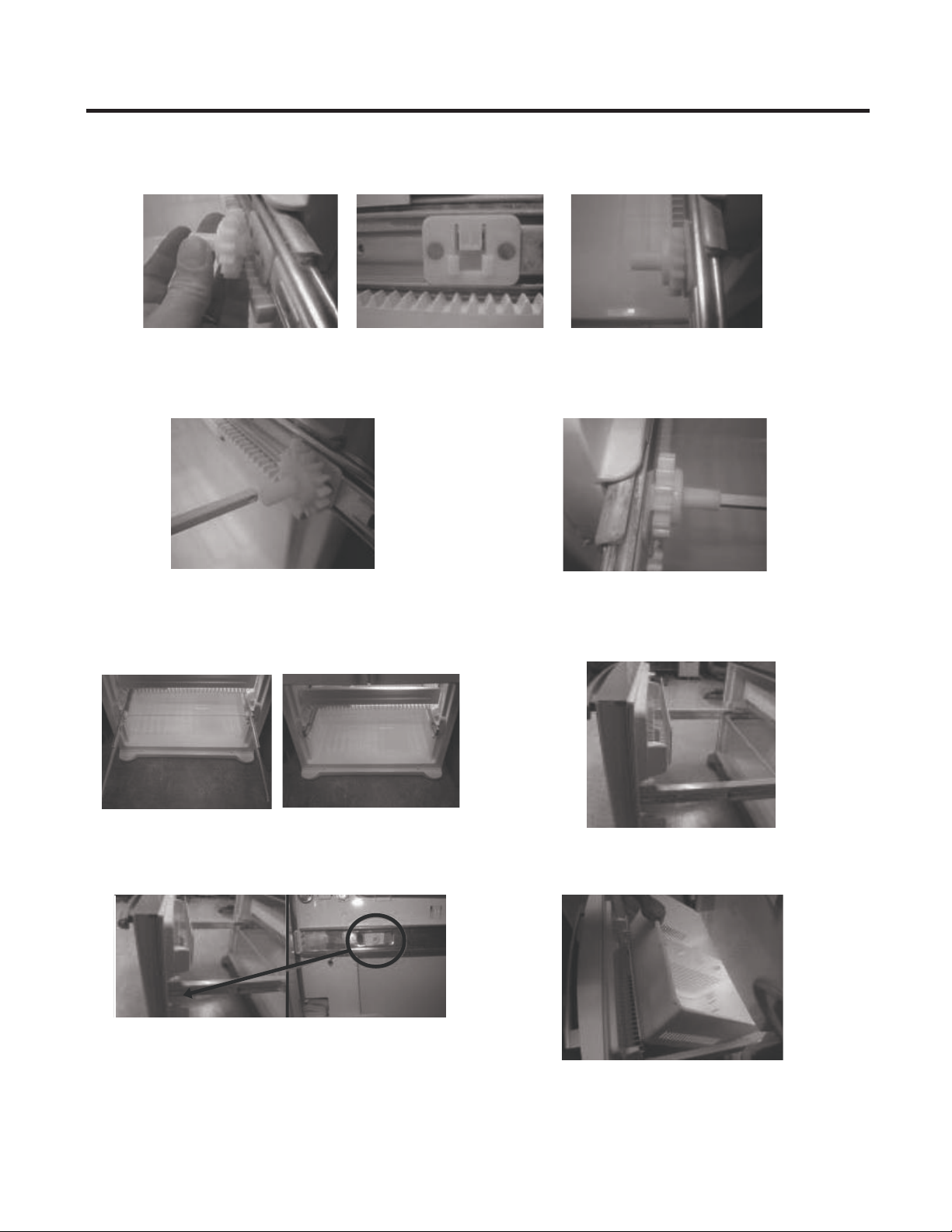

3-9 How to remove and reinstall de pullout drawer ……………………...........…........... 7

3-10 Pullout Drawer …………………………………………………………....................… 9

4-1 Compressor Freezer Drawer model …………………………………………..........… 10

4-2 Compressor Freezer Swing model ………………………………………….......……. 11

4-3 PTC-Starter ………………………………………………………………………....…… 11

4-4 OLP (Overload Protector) …………………………………………………………....… 12

6-1 Main PCB ………………………………………………………………………………… 14

6-2 Display PCB&Sub PCB ……………………………………………………………...…. 14

12-1 Operation principle ………………………………………………………………......... 49

12-2 icemaker functions ……………………………………………………………….......... 50

2