- 10 -

4. ADJUSTMENT

4-2 Introduction of E-Linear Compressor

E-Linear compressor is run by mechanical part design

through automatically varying the cooling power. The

main parts consist of compressor and Sub PCB which

controls the compressor. PCB authorizes constant

voltage and constant frequency to the compressor and

protects it.

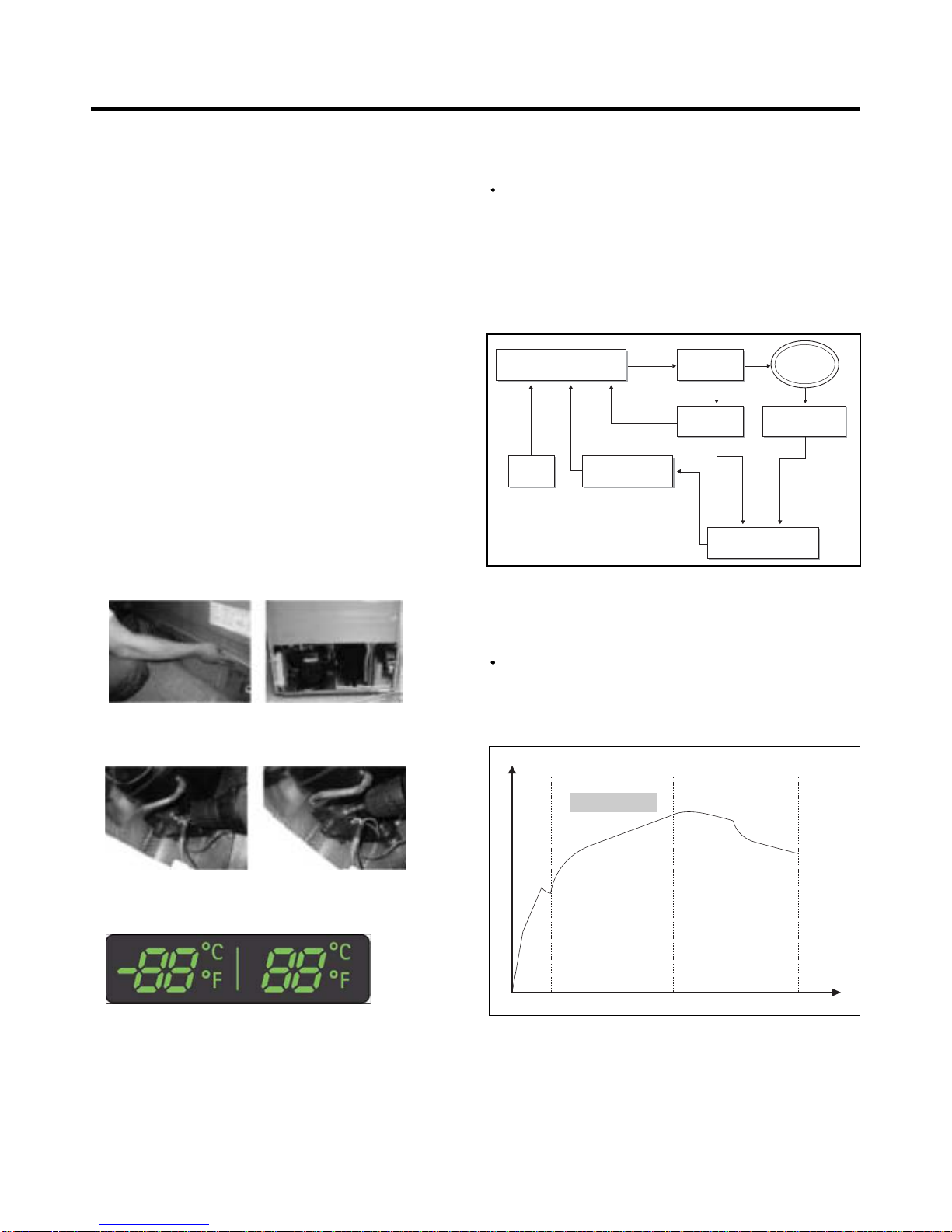

Drive half stroke after turning on initial power for 30

seconds. Then, slowly increase stroke and reach target

input. Once reaching the target input, input naturally

changes according to refrigerator load without any special

control.

Interval 1) Half stroke interval - after initial running, stay at

the initial value for 30 seconds

Interval 2) Running interval - Increase at every 0.8 till it

reaches the target input; it takes about 3’ 45”

Interval 3) CVCF interval - Run by target voltage and main

operating frequency and the input naturally

changes according to refrigerator load

4-1-1 Role

4-1 COMPRESSOR

The compressor intakes low temperature and low pressure

gas from the evaporator of the refrigerator and compresses

this gas to high-temperature and high-pressure gas. It then

delivers the gas to the condenser.

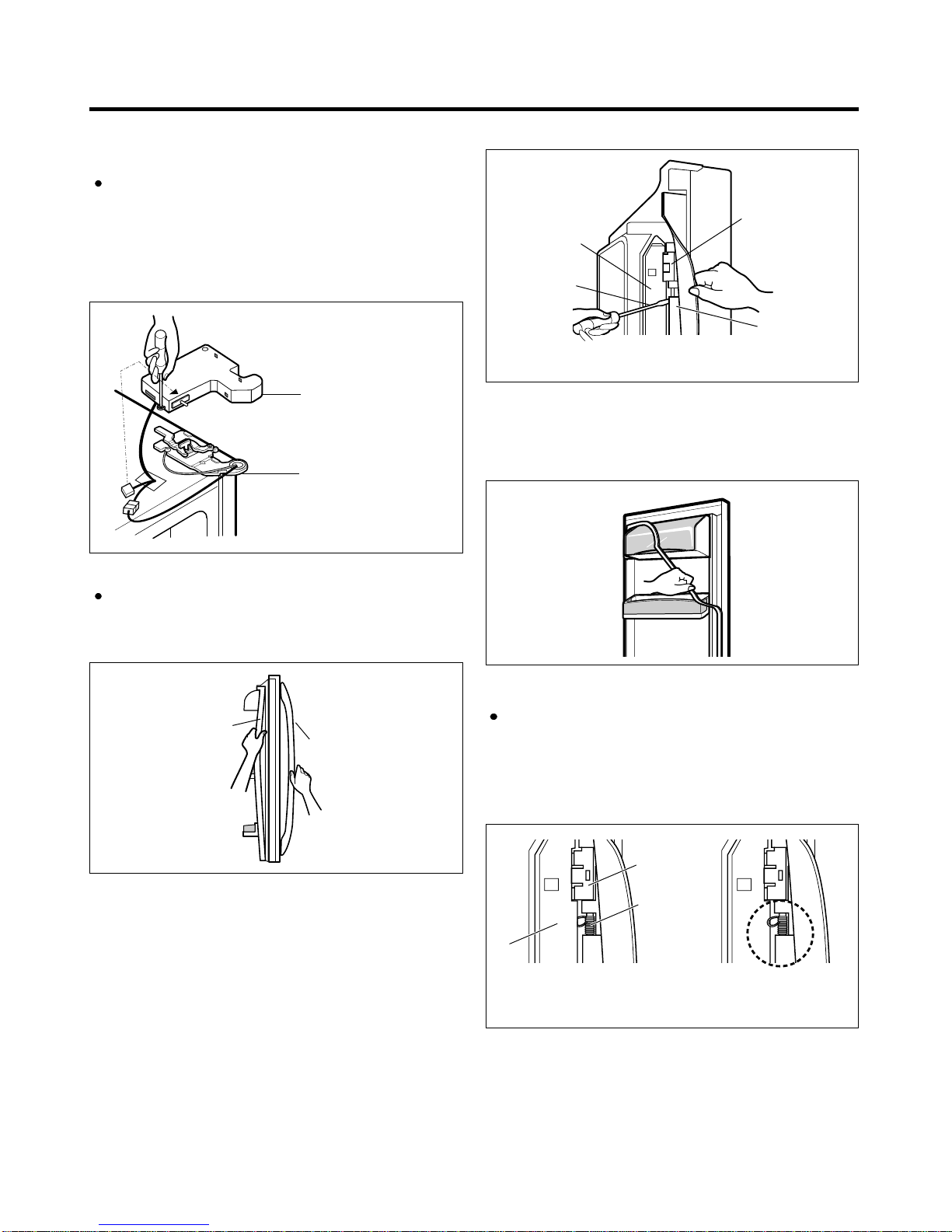

4-1-2 Note for Usage

(1) Be careful not to allow over-voltage and over-current.

(2) Do not drop or handle carelessly.

(3) Keep away from any liquid.

If liquid such as oil or water enters the Cover PTC

Compressor may fail due to breakdown of their

insulating capabilities.

(4) Always use the Parts designed for the compressor and

make sure it is properly attached to the compressor.

Parts may appear physically identical but could have

different electrical ratings. Replace parts by part number

and model number. Use only approved substitute parts.

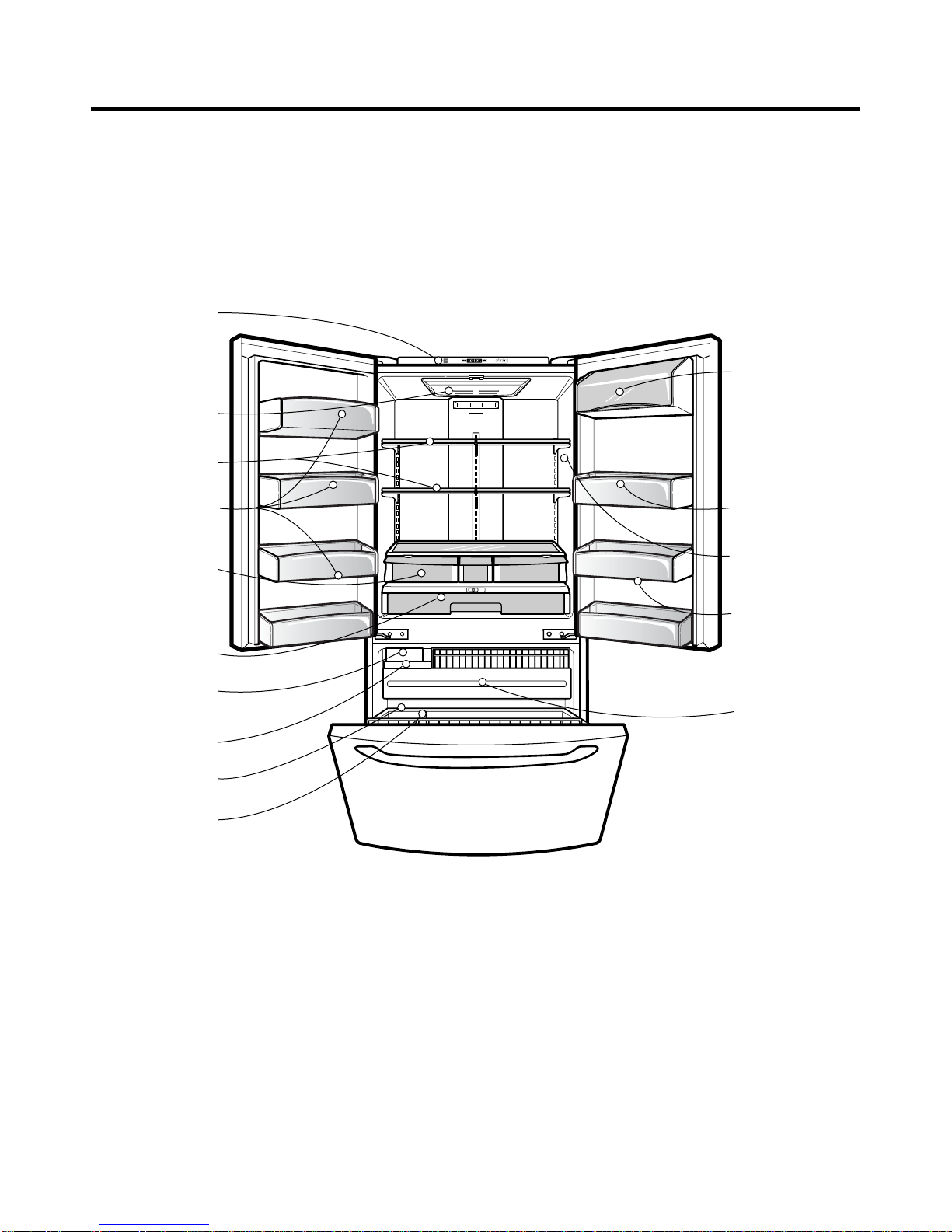

4-1-3 REMOVE THE COVER PTC

(1) Remove the Cover Back M/C

(2) Loosen two screws on comp base

(3) Use a L-shaped flap tooll to pry off the cover

(4) Assembly in reverse order of disassembly

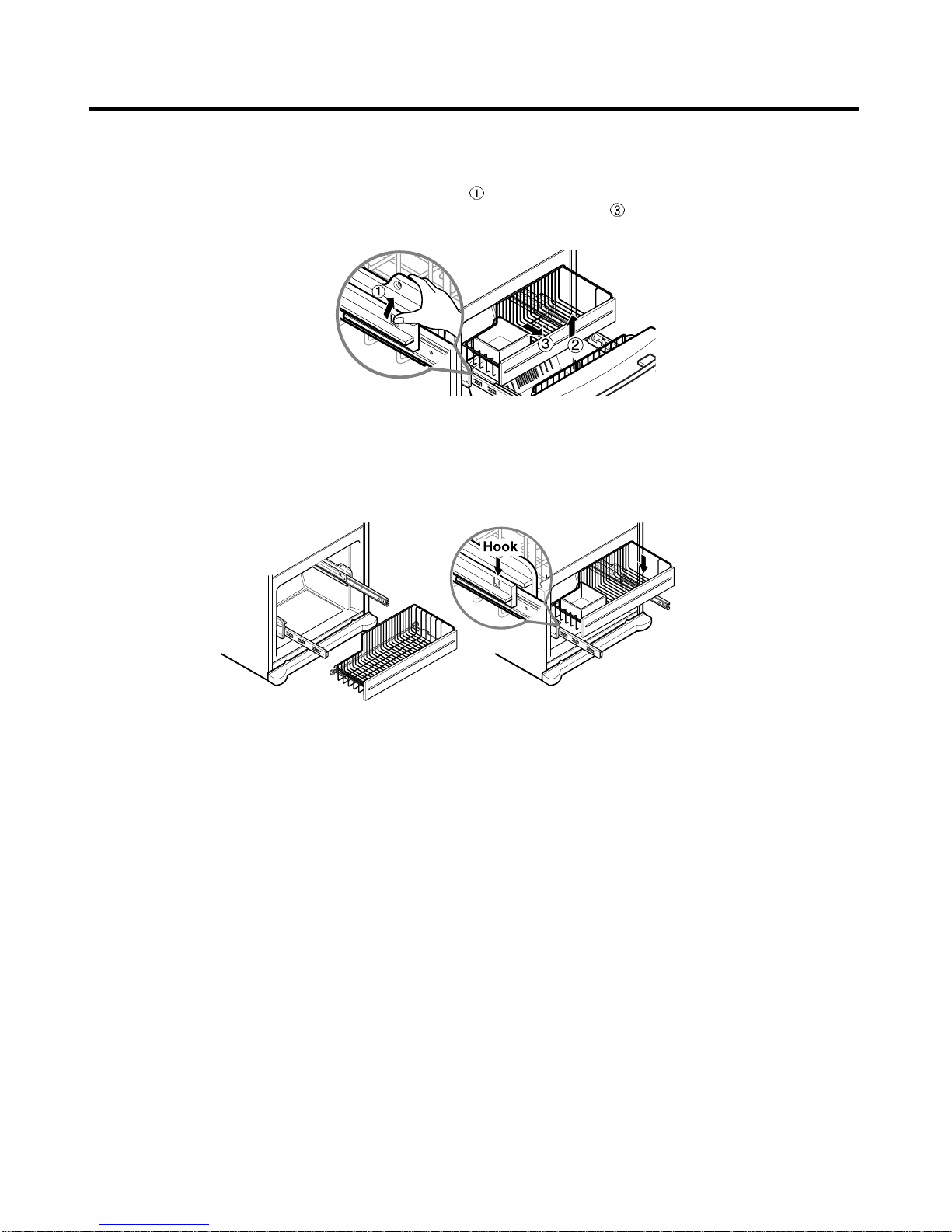

4-2-1 Control of Compressor Block Diagram

4-2-2 Compressor operating pattern

Compressor Controller Inverter

PWM

Signal

Frequ

-ency

Linear

Comp

DC link

Voltage

Main

Micom

Calculate counter

electromotive force

Counter elec-

tromotive force

Vcap Voltage

Control Block Diagram of Compressor

Comp. input