CONTENTS

SAFETY PRECAUTIONS ........................................................................................................

1. SPECIFICATIONS ...............................................................................................................

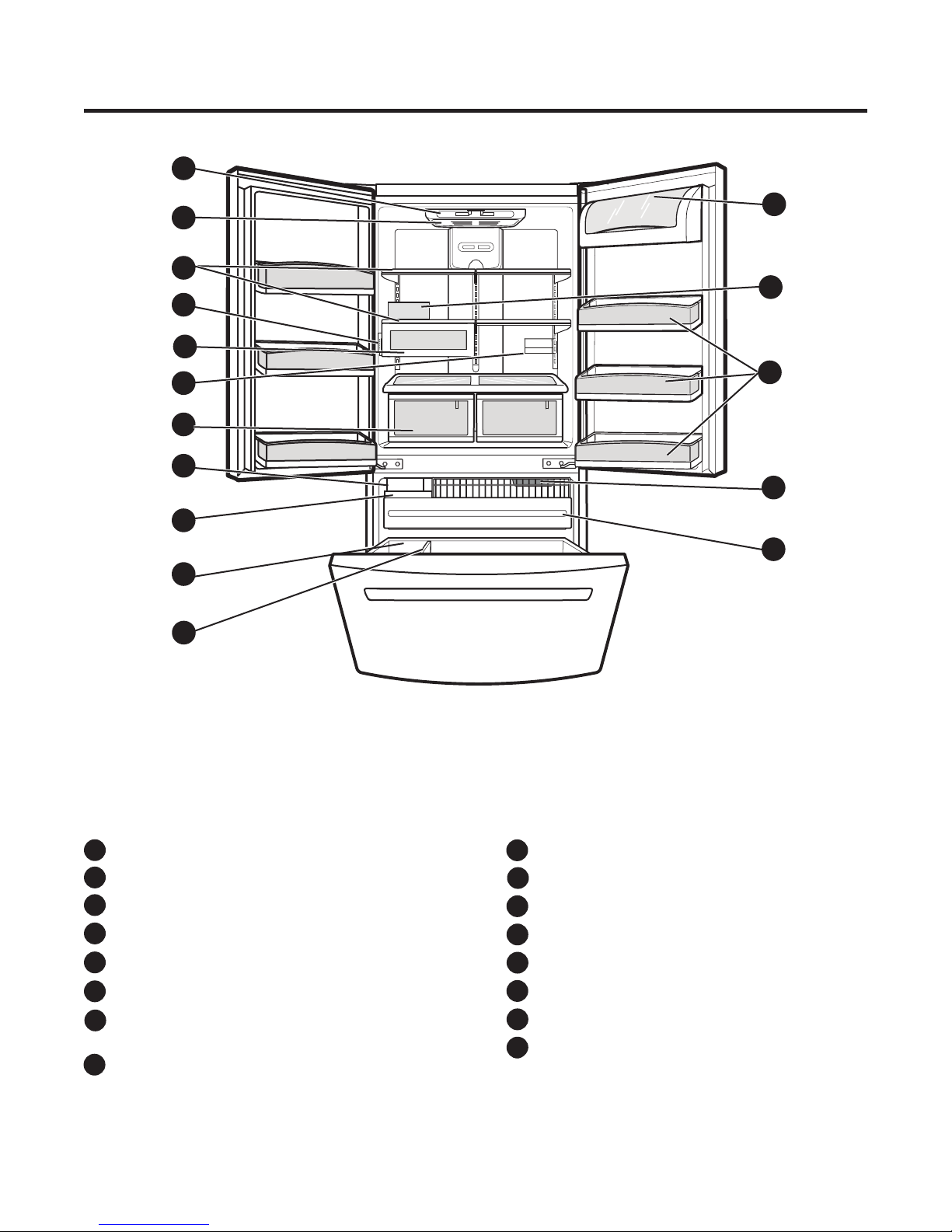

2. PARTS IDENTIFICATION ....................................................................................................

3. DISASSEMBLY ...................................................................................................................

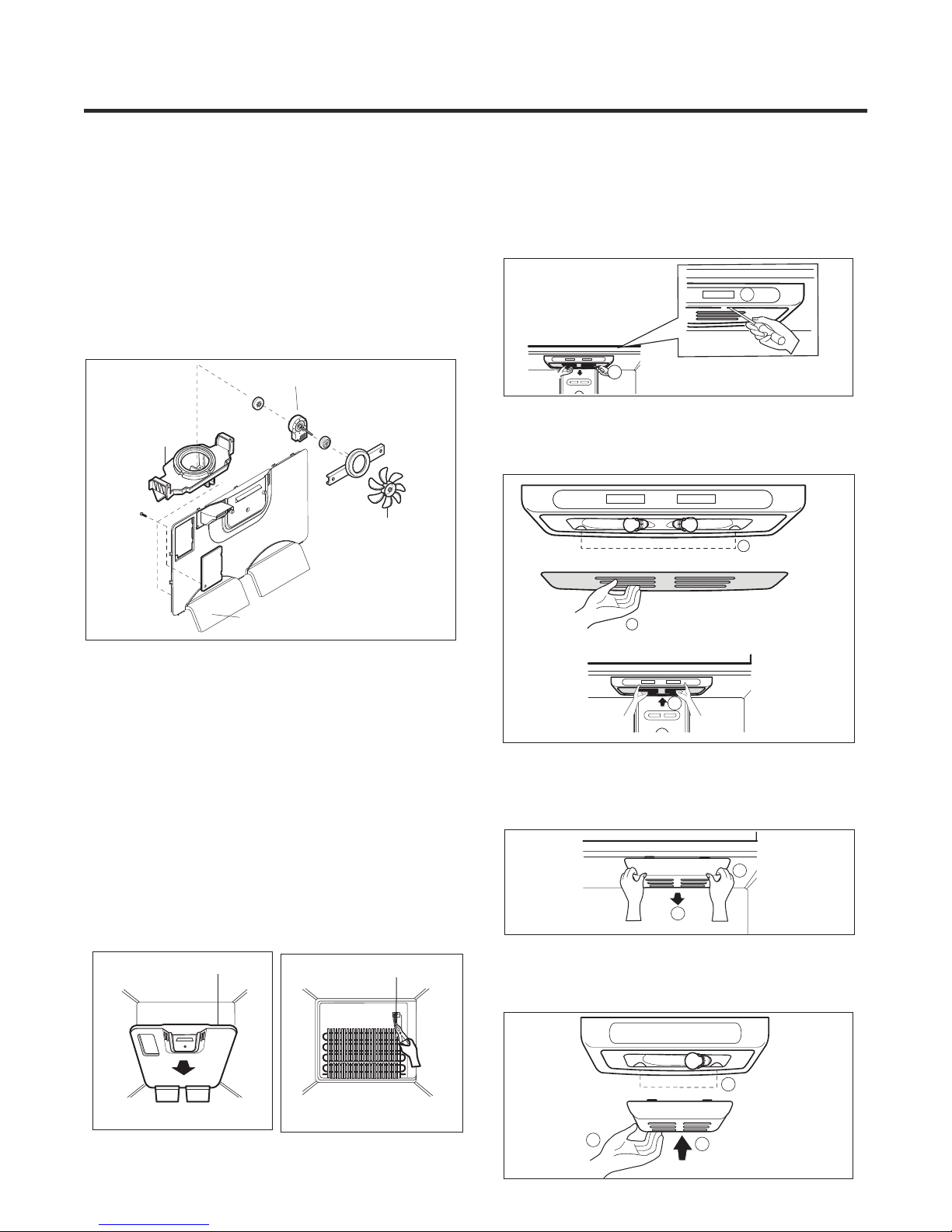

3-1 Fan and Fan Motor..........................................................................................................

3-2 Defrost Control Assembly.................................................................................................

3-3 Lamp................................................................................................................................

3-4 Control Box Refrigerator..................................................................................................

3-5 Multiduct..........................................................................................................................

3-6 Cover Valve......................................................................................................................

3-7 Door Disassembly............................................................................................................

3-8 How to remove the Door Handle.....................................................................................

3-9 How to remove Pull out drawer........................................................................................

3-10 Closing and aligning the doors......................................................................................

4. ADJUSTMENT ....................................................................................................................

4-1 Compressor ...................................................................................................................

4-2 PTC-Starter ....................................................................................................................

4-3 OLP (overload protector) ...............................................................................................

5. CIRCUIT DIAGRAM ............................................................................................................

6. TROUBLESHOOTING ........................................................................................................

6-1 Compressor and electric components ...........................................................................

6-2 PTC and OLP .................................................................................................................

6-3 Other electrical components ..........................................................................................

6-4 Service diagnosis chart ..................................................................................................

6-5 Refrigeration cycle .........................................................................................................

7. OPERATION PRINCIPLE AND REPAIR METHOD OF ICEMAKER ..................................

7.1 Operation principle .........................................................................................................

7.2 Ice maker functions ........................................................................................................

8. CIRCUIT OF MICOM............................................................................................................

8.1 Function .........................................................................................................................

8.2 PCB function ..................................................................................................................

8.3 Resistance specification of sensor .................................................................................

9. EXPLODED VIEW ................... ............................................................................................

3

4

5

6

6

6

6

7

7

9

10

12

14

16

17

17

17

18

19

20

20

21

22

23

24

26

26

27

30

30

34

38

39

- 2 -