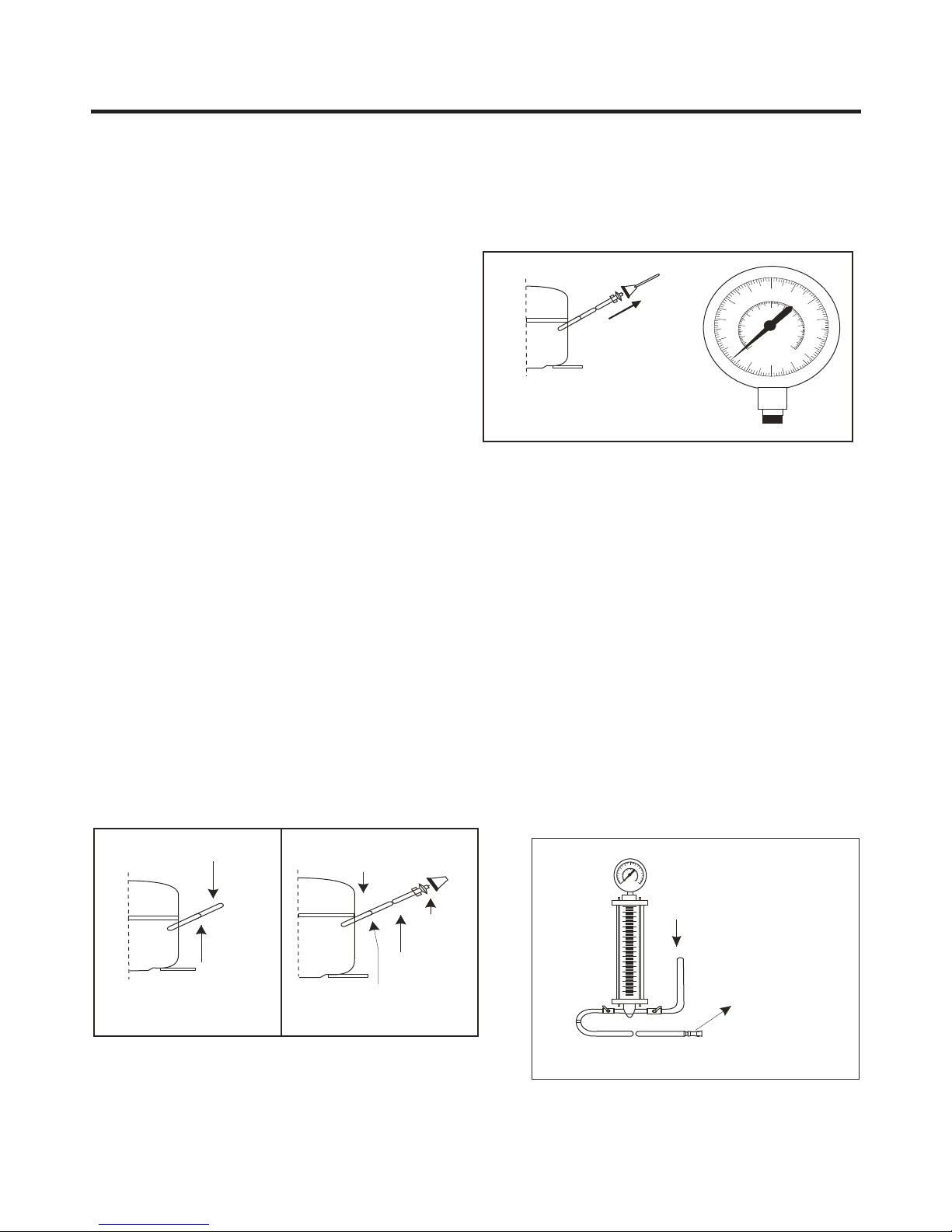

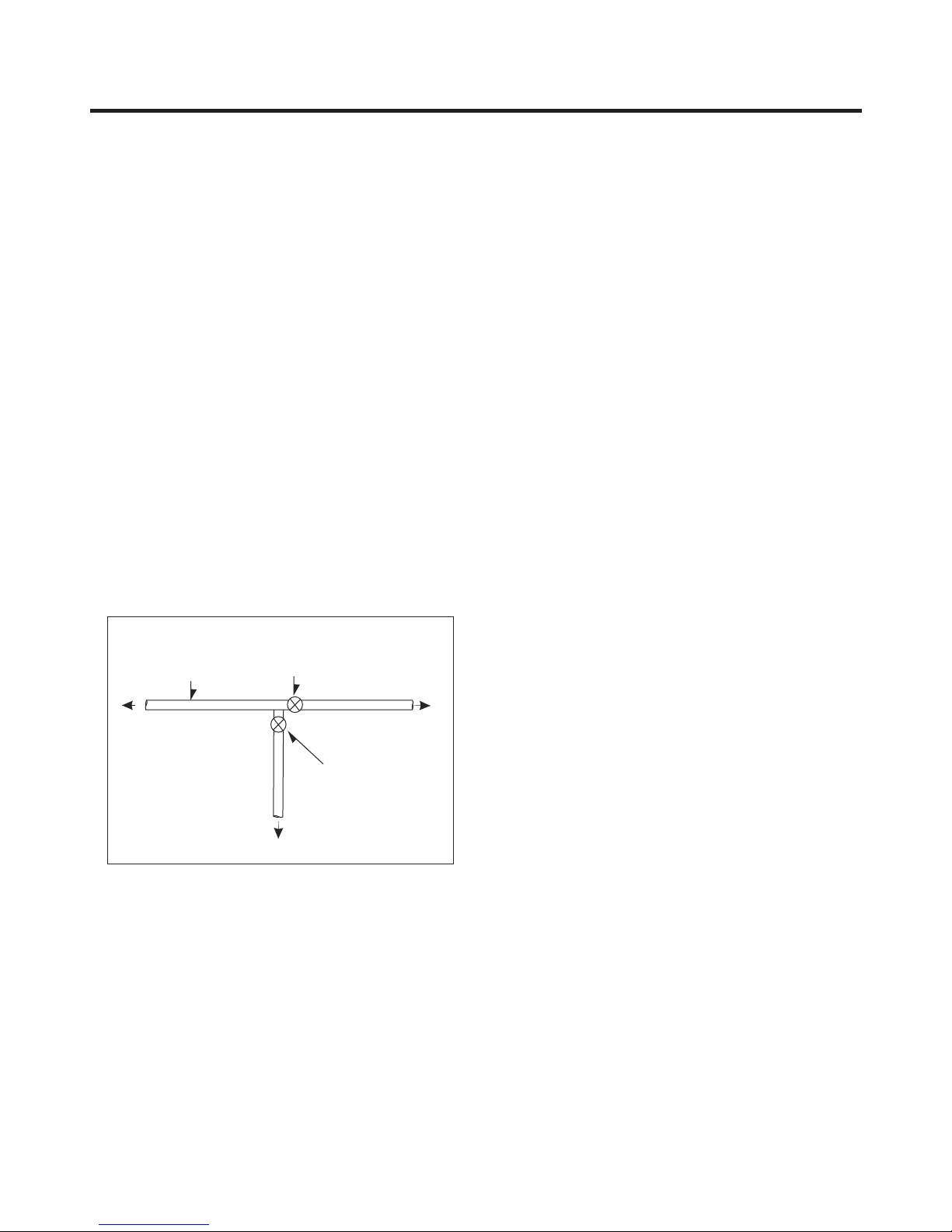

PTC

36

S

5

M

SM

TERMINAL

HERMETIC

OLP (OVERLOADED PROTECTOR)

PTC STARTER

RSIR

COMPRESSOR

Figure 20

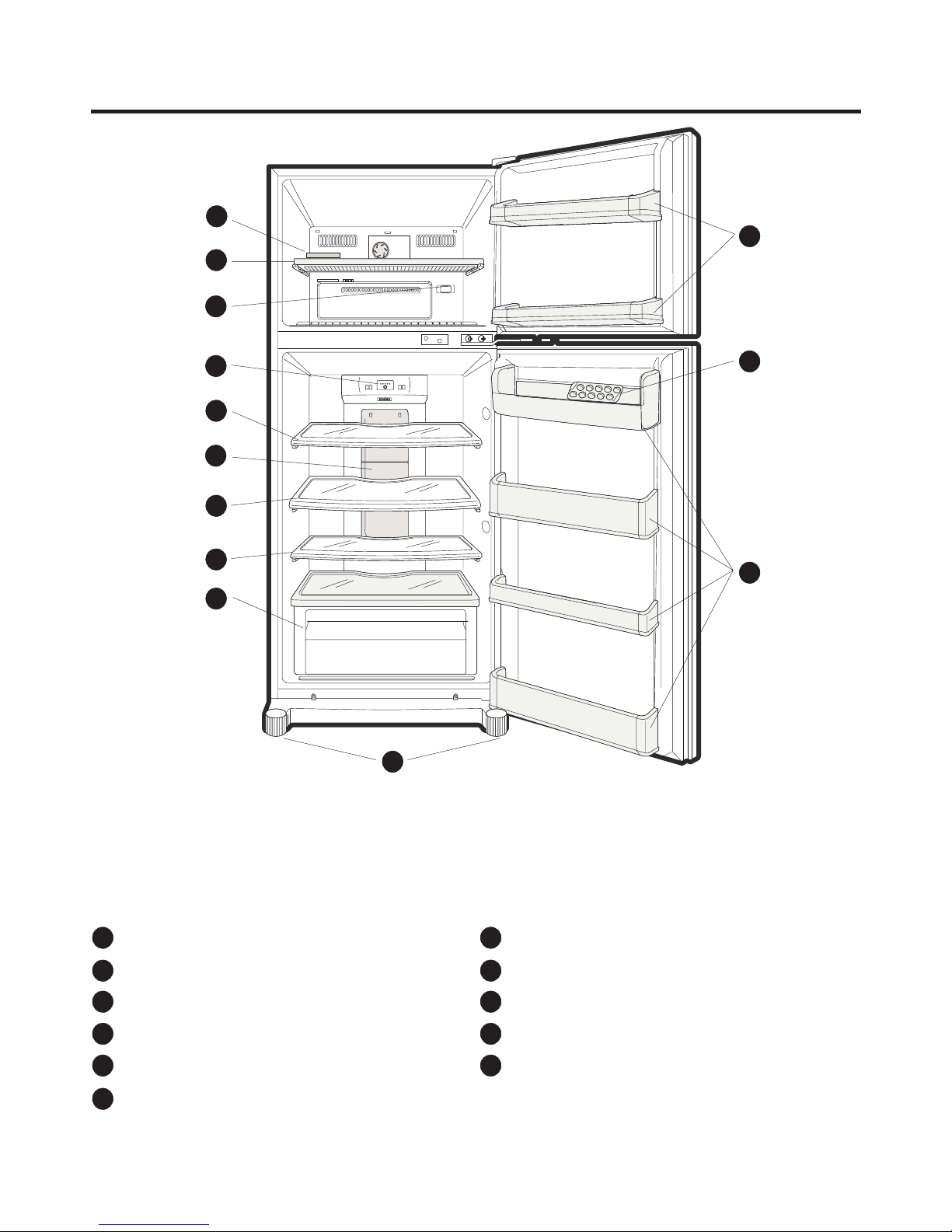

4-1 COMPRESSOR

4-1-1 Function.

4-2-3 PTC- Circuit Diagram Applied.

- 9 -

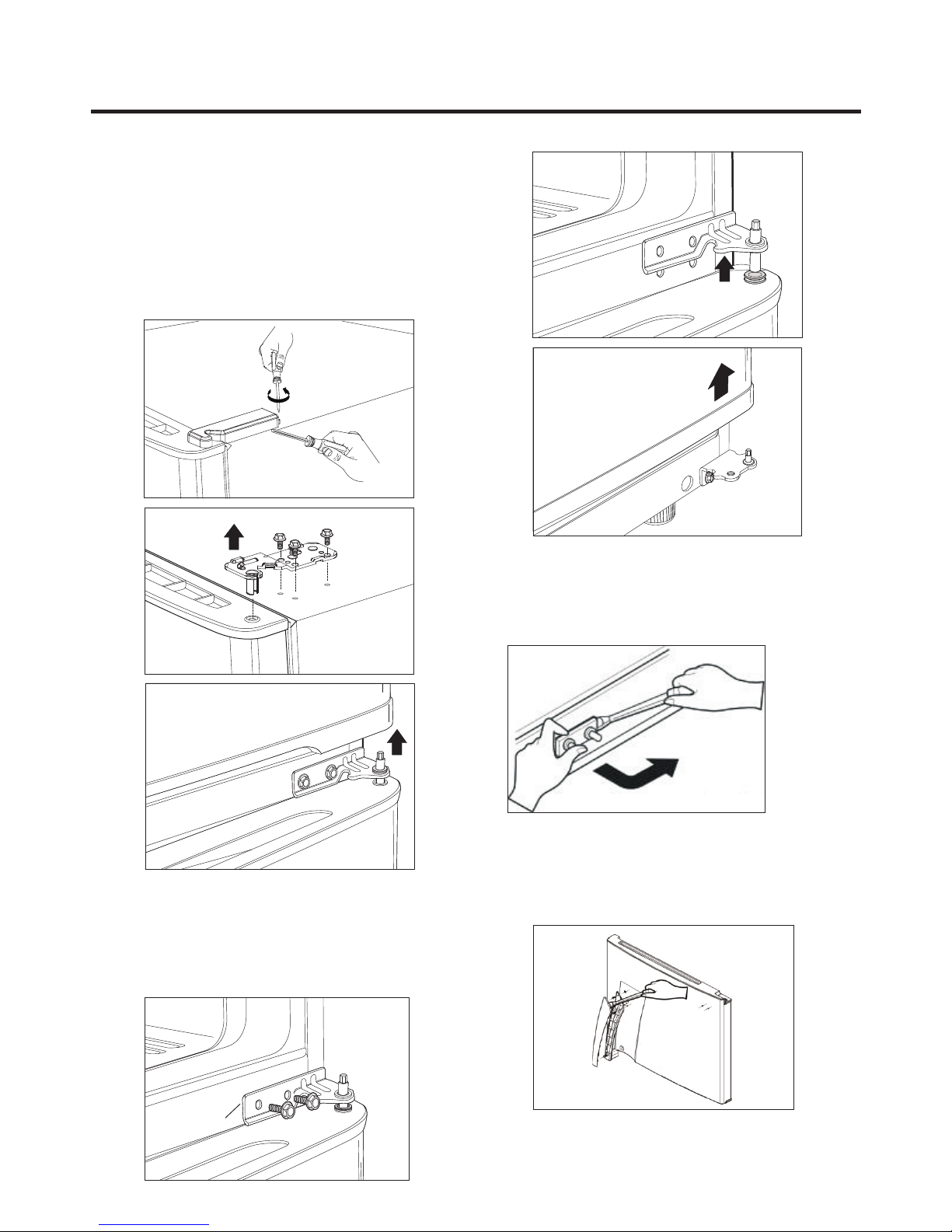

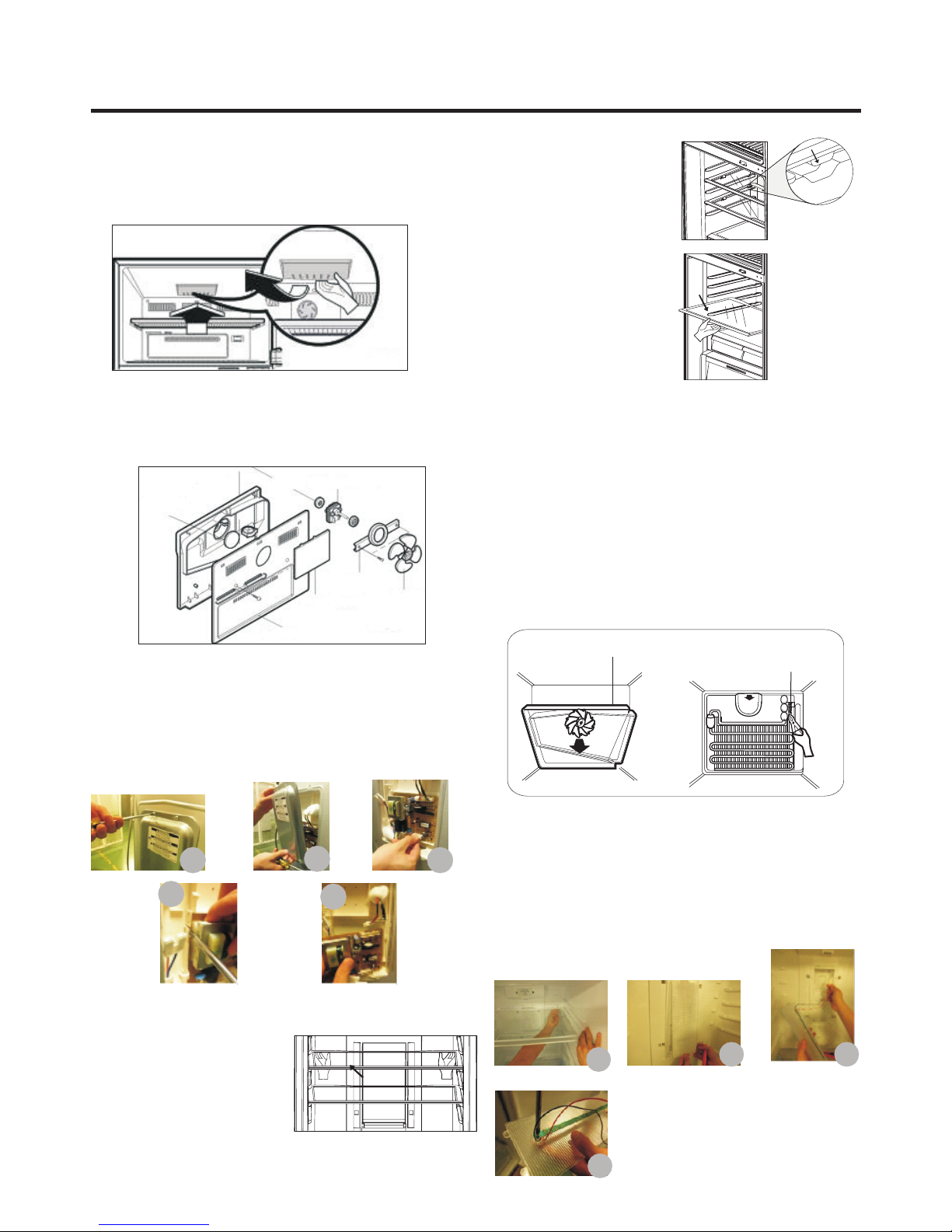

4. ADJUSTMENTS

The compressor sucks evaporated gas in low pressure and

lowers the temperature form the evaporator or fridge and

compress this gas at high temperature and high pressure

and passes it on to the condenser.

• According to starting motor method.

4-1-2 Composition.

Compressor is made up of a system that compresses the

gas, the motor of the compressor and the cover that protects

the device. On the exterior of the compressor is found the

PTC (thermistor) and the OLP (overload protector).

Treat and repair in carefully, because it contains components

of processing accuracy of 1/1000 mm and is sealed dust or

moisture after manufacture.

4-1-3 Notes for use.

(1) Protect your refrigerator of an over voltage or over

current.

(2) Do not hit:

If is forced or hit (dropping or careless treatment), Noise can

originate or have an inefficient operation.

(3) Use appropriate electrical components for the

compressor.

(4) Note for storing the compressor: If the compressor gets

wet during rain and oxidized in the hermetic terminal, may

have a poor operation and cause poor contact.

(5) Ensure that dust, moisture and soldering flux are not

introduced to the compressor during its replacement. Dust,

moisture or flux are introduced to the pipe can cause noise or

clog it.

4-2-1 PTC Composition

(1) The PTC (thermistor) is a semiconductor component that

uses starting ceramic material which is composed of

BaTiO 3.

(2) The higher the temperature, the greater the resistance

value. These characteristics are used for engine starting.

4-2 PTC STARTER

4-2-2 PTC Function

(1) The PTC is attached to the hermetic compressor and is

used for starting the refrigerator compressor.

(2) The compressor of a household refrigerator, uses a motor

of an induction phase, the normal engine operation is started

at the time of starting, the current flows through the auxiliary

winding. Once the boot is completed, the current is cut in the

auxiliary winding because the PTC is connected in series

and this increases its resistance. The characteristics of the

PTC have the above functions. Then, the PTC is used as an

engine starting system.

4-2-4 Restarting the engine and cooling of the PTC

(1) For the restart after power failure during normal operation

of the compressor motor, connect the power cord after 5

minutes for the pressure of the refrigeration cycle to stabilize

and cool the PTC.

(2) During normal operation of the compressor motor, the

elements of PTC generate heat continuously. Hence, if the

PTC is not cooled at some time after power failure, the

engine could not operate again.

4-2-5 Relation between the PTC and OLP

(1) If your power goes out during operation of the

compressor and is reestablished before the PTC has cooled,

(off in a span of 2 minutes or reconnect the power cord due

to a bad connection), the PTC cooling is reached and the

resistance value increases. As a result, the current cannot

flow to the auxiliary winding and the motor cannot start,

because the OLP operates on current flow through the main

winding.

(3) While the OLP repeat the operation on and off about 3 to

5 times, the PTC cools the compressor and the engine

operates normally. If the OLP does not operate when the

PTC is hot compressor motor will overheat causing a short

circuit or even fire. Then, use a flawless OLP.

4-2-6 Note for Using the PTC-Starter

(1) Be careful not to allow over-voltage and over-current.

(2) Do not drop or handle carelessly.

(3) Keep away from any liquid. If liquid such as oil or water

enters the PTC, PTC materials may fail due to breakdown of

their insulating capabilities.

(4) Do not change the PTC at your own convenience. Do not

disassemble the PTC or the mold. Damage to the exterior of

the PTC, the resistance value is altered and can cause

failures on the compressor motor. Use a PTC in good

conditions.