10

5. OPERATION

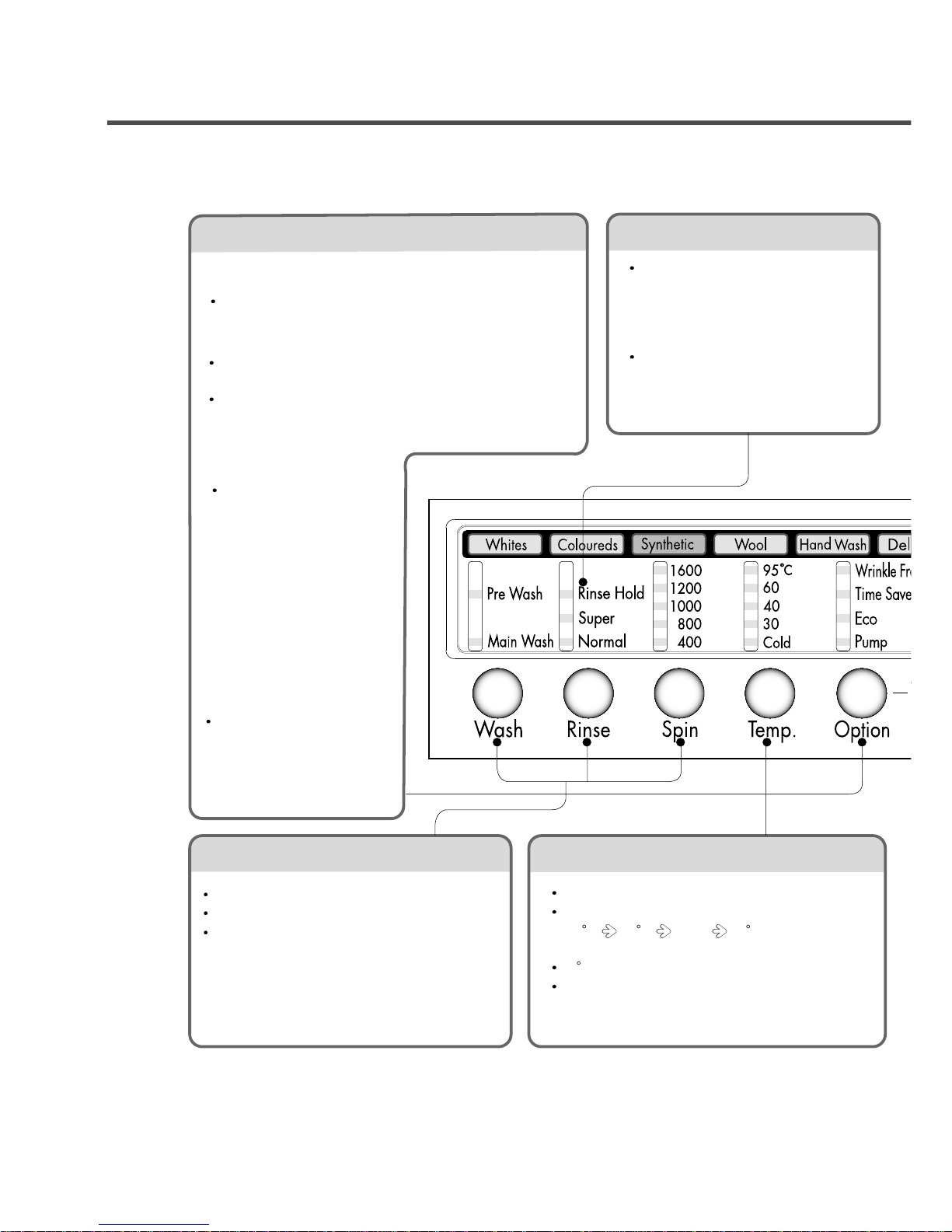

Water temperature selector

Press the button to select water temperature.

The water temperature

[40 C 60 C Cold 30 C] can be selected

in Coloureds or Synthetic.

95 C is selected for Whites only.

By pressing the button while operating the washer,

the present temperature is displayed.

For manual wash, rinse and spin speed

Use these buttons to change wash/rinse/spin.

When lamp is off, no selection has been made.

Prewash is available for coloureds, whites,

white-eco, and synthetic.

Time Save

If is possible in Whites, Coloureds, Synthetic, Wool, Hand

Wash, Delicate programs.

By selecting the Time Save option, the wash time may be

reduced, depending on the program selected.

Rinse hold

If you desire to leave fabrics in the

machine without spinning after rinse

to prevent wrinkling, you may select

rinse Hold by pressing the Rinse

button.

To drain and spin, press the Rinse

button or Start/Pause button to turn

off the Rinse Hold lamp.

Pump

If you want to drain only,

select this function and

press the Start/Pause

button.

Eco

By selecting Eco, the

water temperature is

reduced and washing time

is lengthened. So you can

economize in your

consumption of energy.

[You can select Eco when

temperature is higher than

60˚C in Whites, Coloureds

and Synthetic.]

Wrinkle Free

If you want to prevent wrinkle, select this option with spin.

[WD(M)-14110(5)FD(F/N) / 16110(5)FD(F/N)]

Option