LG ( 6023C / 8023C / 1023C) SUPER-SLIM WASHING MACHINES

Page 9

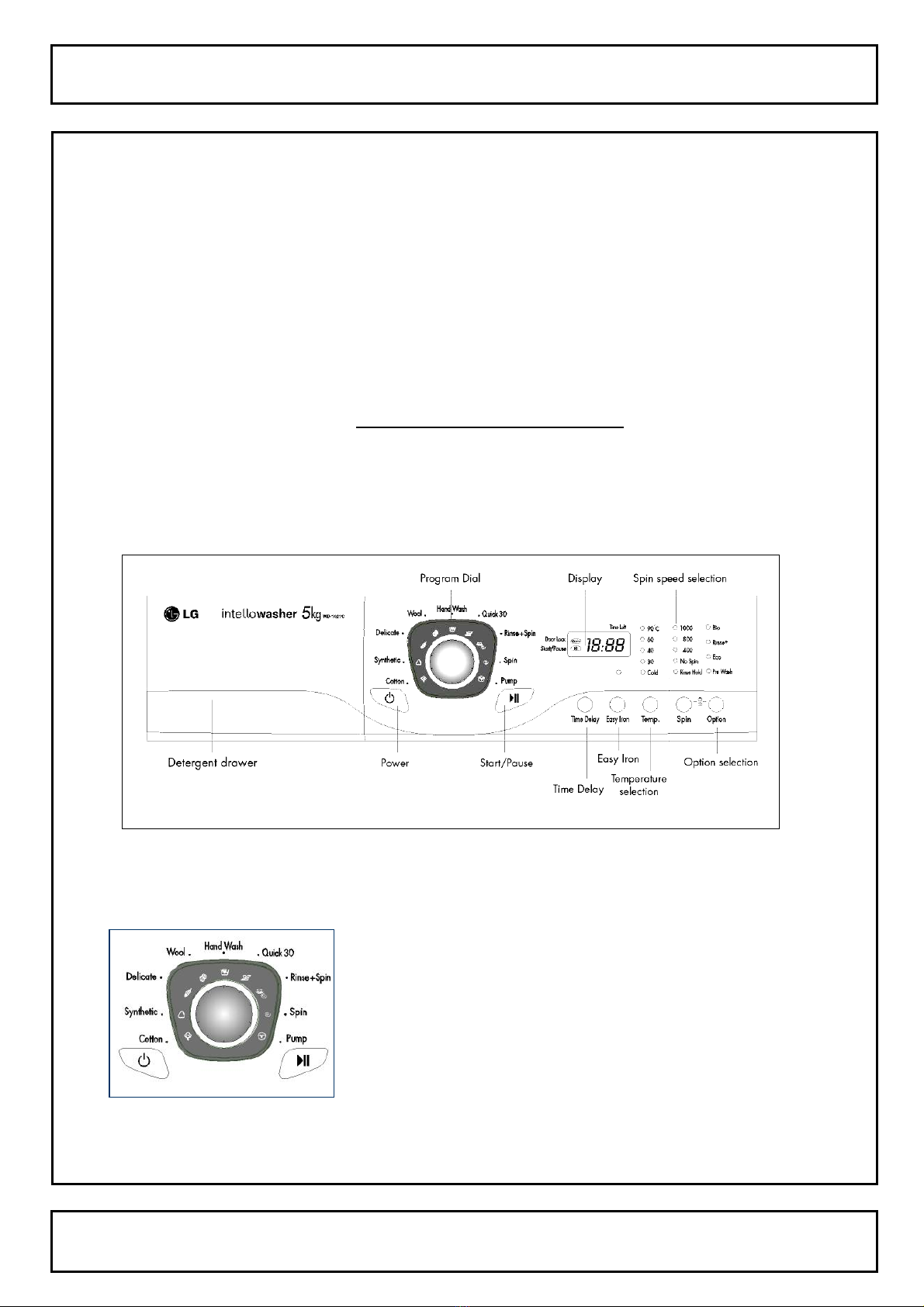

In order to open the front door pulls the holder (Figure-3). To run the machine, front door

should be closed, program and other options should be selected and Start/Pause button

should be pressed.

Figure-3

Due to the quality control process during production, there may be some water left over in

your machine. This does not cause any damage to your product. So the hence operation

for the first time should be empty. One portion powder detergent should be put into the

second compartment of the drawer. Program “Quick30” should be selected and cold

position of the thermostat should be adjusted and the machine should be run as such.

4-Operation / Grouping the cloths and Loading the W/M

Sort the laundry according to the following groups and wash them separately:

• White and resistant colored fabrics,

• Colored fabrics,

• Delicate fabrics (silk, rayon etc.),

• Wool.

Make sure to empty pockets and remove any belts, buttons, pins, etc. from the clothing.

Place the fabrics uniformly inside the machine. Hand knits should be placed inside out in

the machine. Make sure that there is no clothing at the side of the door. Close the door by

pushing lightly. If the door does not close completely, the machine could not be started at

safety measure. Front door is locked until the end of the washing program and it will not be

opened about 2 minutes following the end of the program.