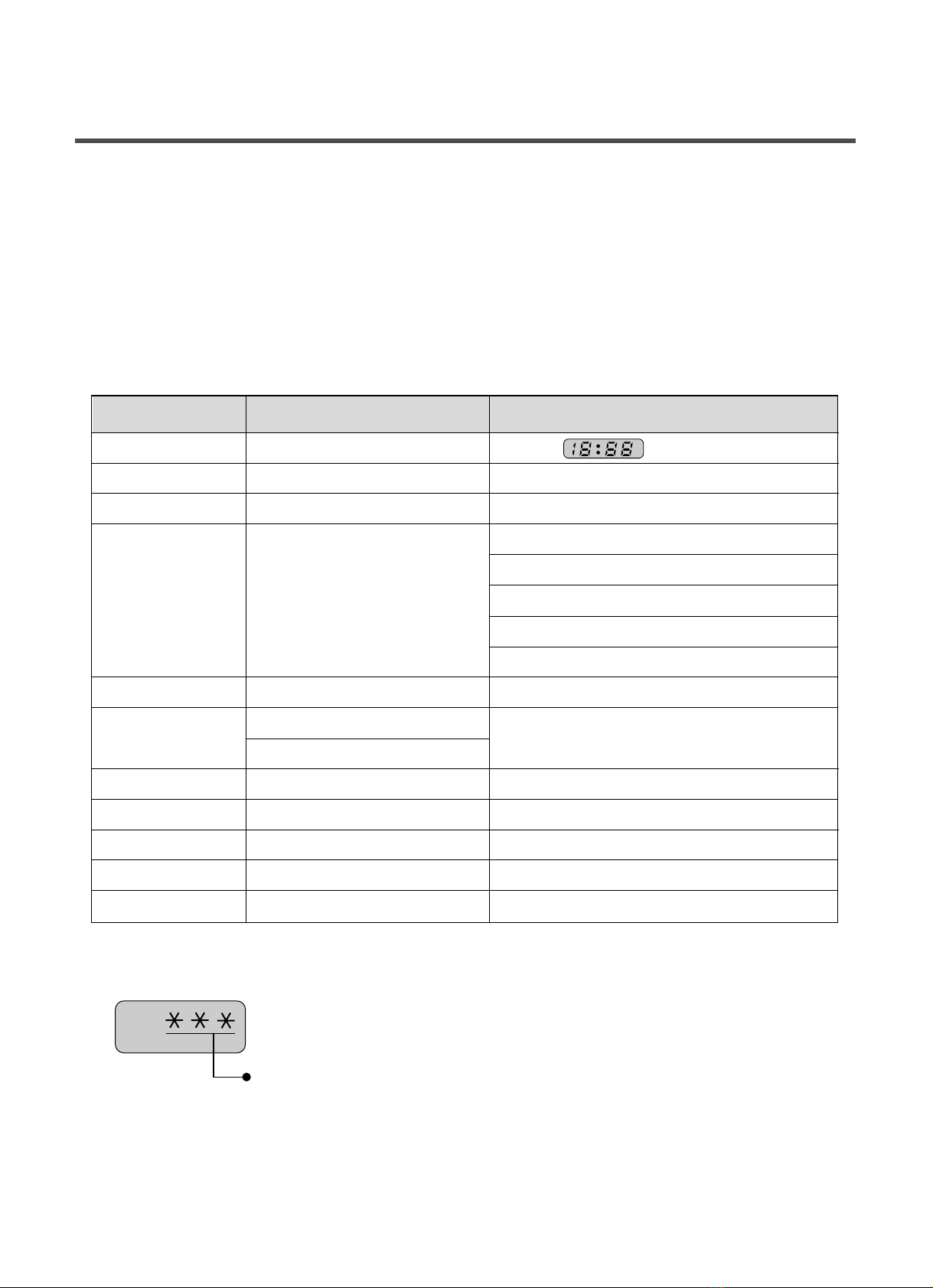

ERROR SYMPTOM CAUSE

8

9

10

•The electric contact between the connectors

(5 pin, male in the Wire Harness and 5 pin female in the Hall Sensor) is

bad or unstable.

ƒ_Reconnect or repair the contact in the connector

•The connector (6 pin, male, natural) in the Wire Harness is not

connected to the connector (6 pin, female, natural) of PWB

ASSY(Main) or the electric contact of connectors is bad/unstable.

ƒ_Reconnect or repair the contact in the connector

•The electric contact between the connectors¡a6 pin, male in the Wire

Harness and 6 pin female in the controller(Main)¡bis bad or unstable.

ƒ_Reconnect or repair the contact in the connector

•The Wire Harness between Hall Sensor in the MOTOR and PWB

ASSY(Main) is cut(open circuited).

ƒ_Repair/replace the damaged WIRE HARNESS

•The Hall Sensor is out of order/defective.

ƒ_Replace the Motor

•The controller(Main) is out of order/defective.

ƒ_Replace the PWB ASSY(Main)

•PWB ASSY(Main) is out of order

ƒ_Replace the PWB ASSY(Main)

•Winding in the MOTOR is short-circuited.

ƒ_Replace the MOTOR

•The Connector(3 pin, male, white) in the Wire Harness is not

connected to the Connector(3 pin, female, white) of MOTOR.

ƒ_Reconnect or repair the connector

•The electric contact between the connectors¡a3 pin, male, white in the

Wire Harness and 6 pin, female, white in the PWB ASSY(Main)¡bis bad

or unstable.

ƒ_Reconnect or repair the contact in the connector

•The Wire Harness between the MOTOR and PWB ASSY(Main) is

cut(open circuited).

ƒ_Repair the damaged(open-circuited) WIRE HARNESS

•The hall sensor is out of order/defective.

ƒ_Replace the PWB ASSY(Main)

SENSOR

ERROR

CURRENT

ERROR

LOCK

ERROR

16