CONTENTS

1. Specifications .................................................................................................................................. 3

2. Features and Technical Explanation ............................................................................................ 4-6

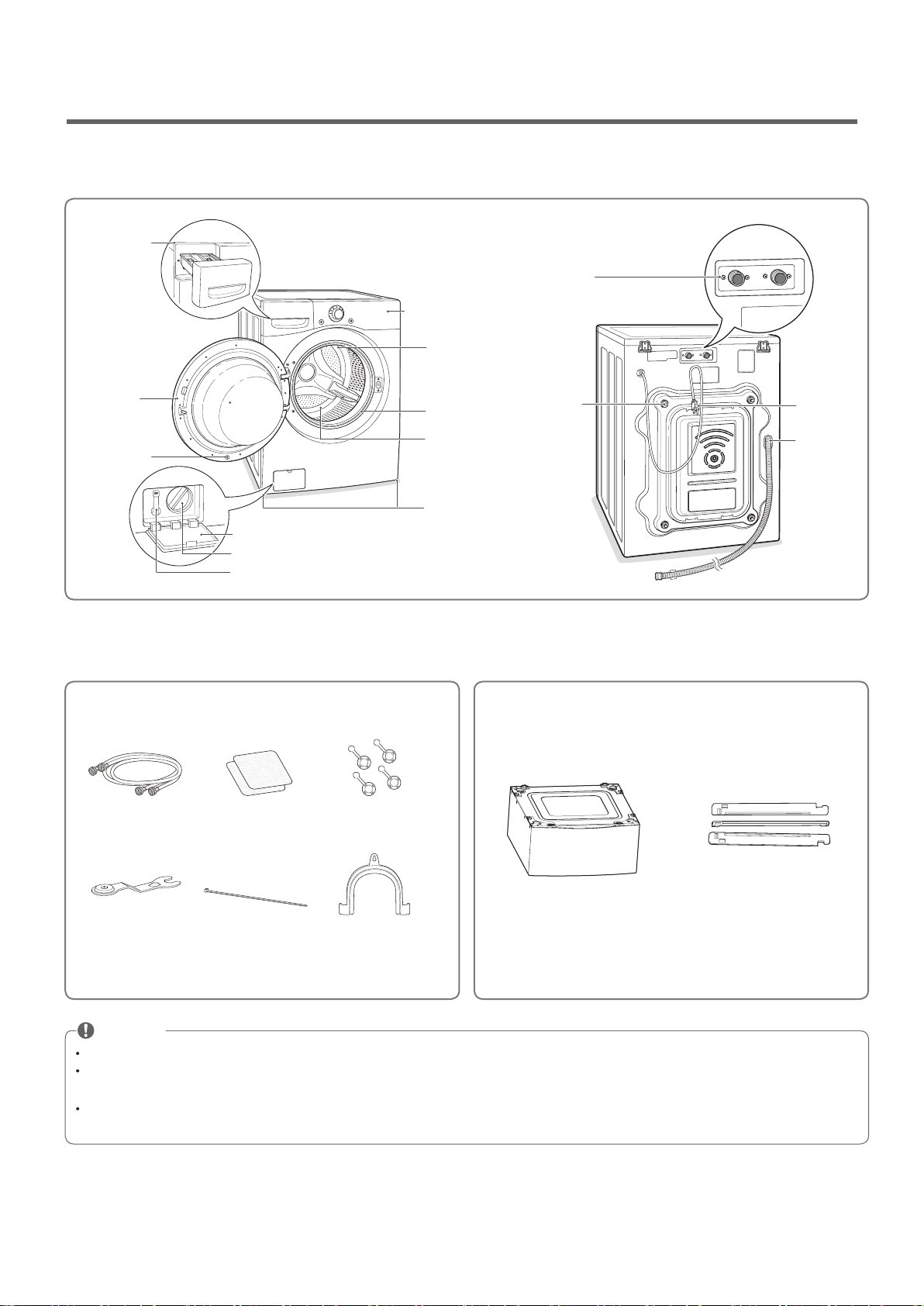

3. Parts Identification ........................................................................................................................... 7

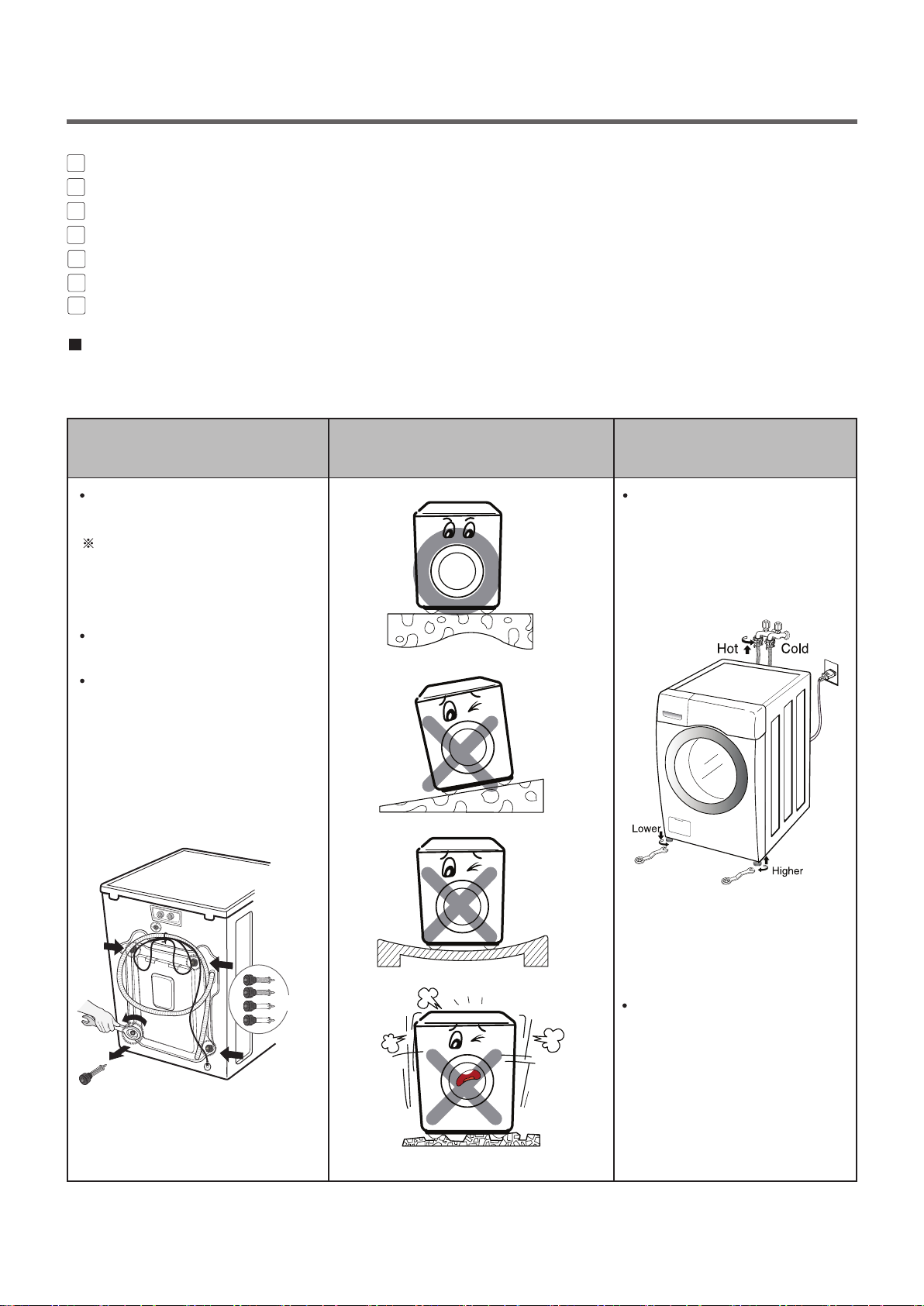

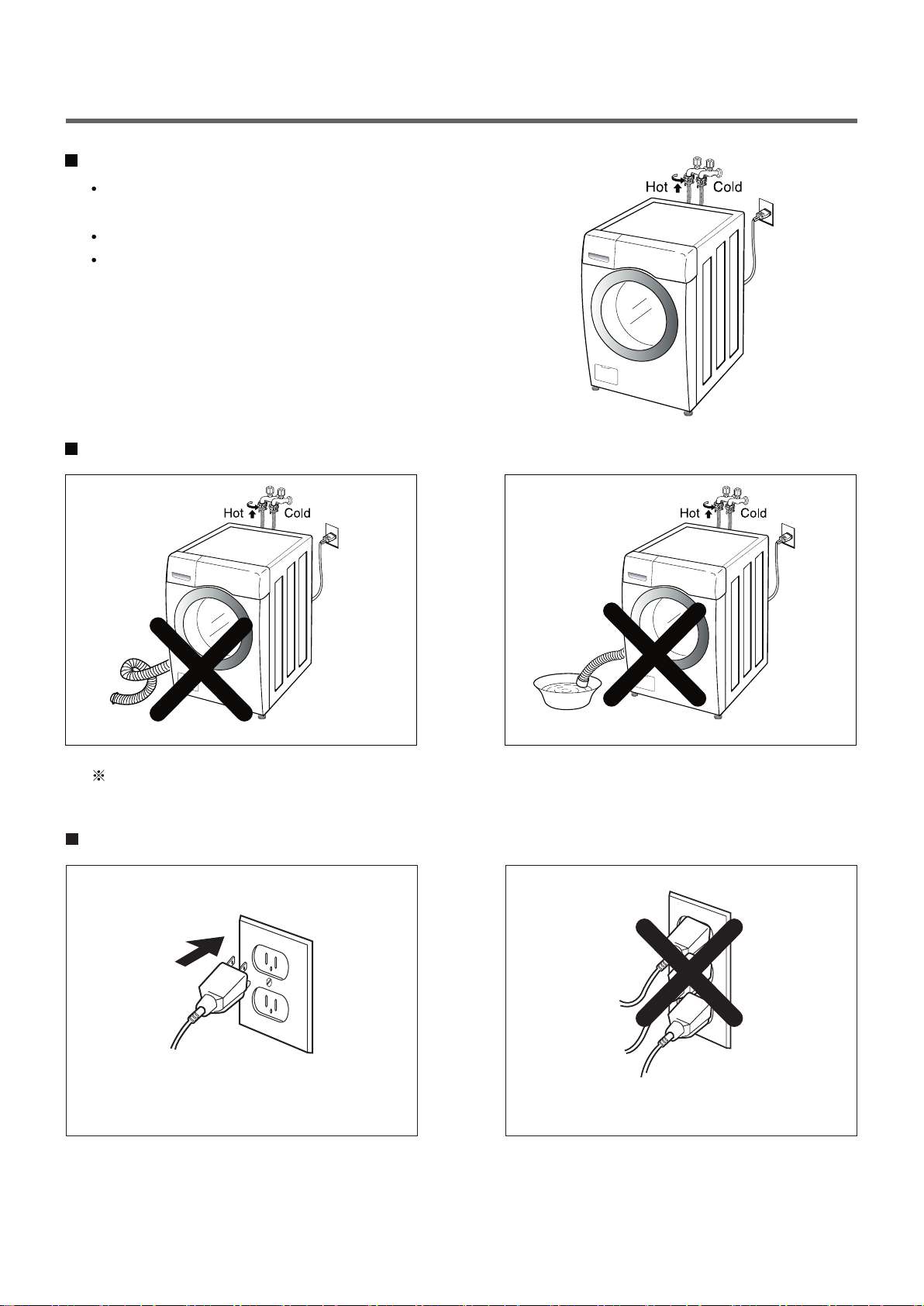

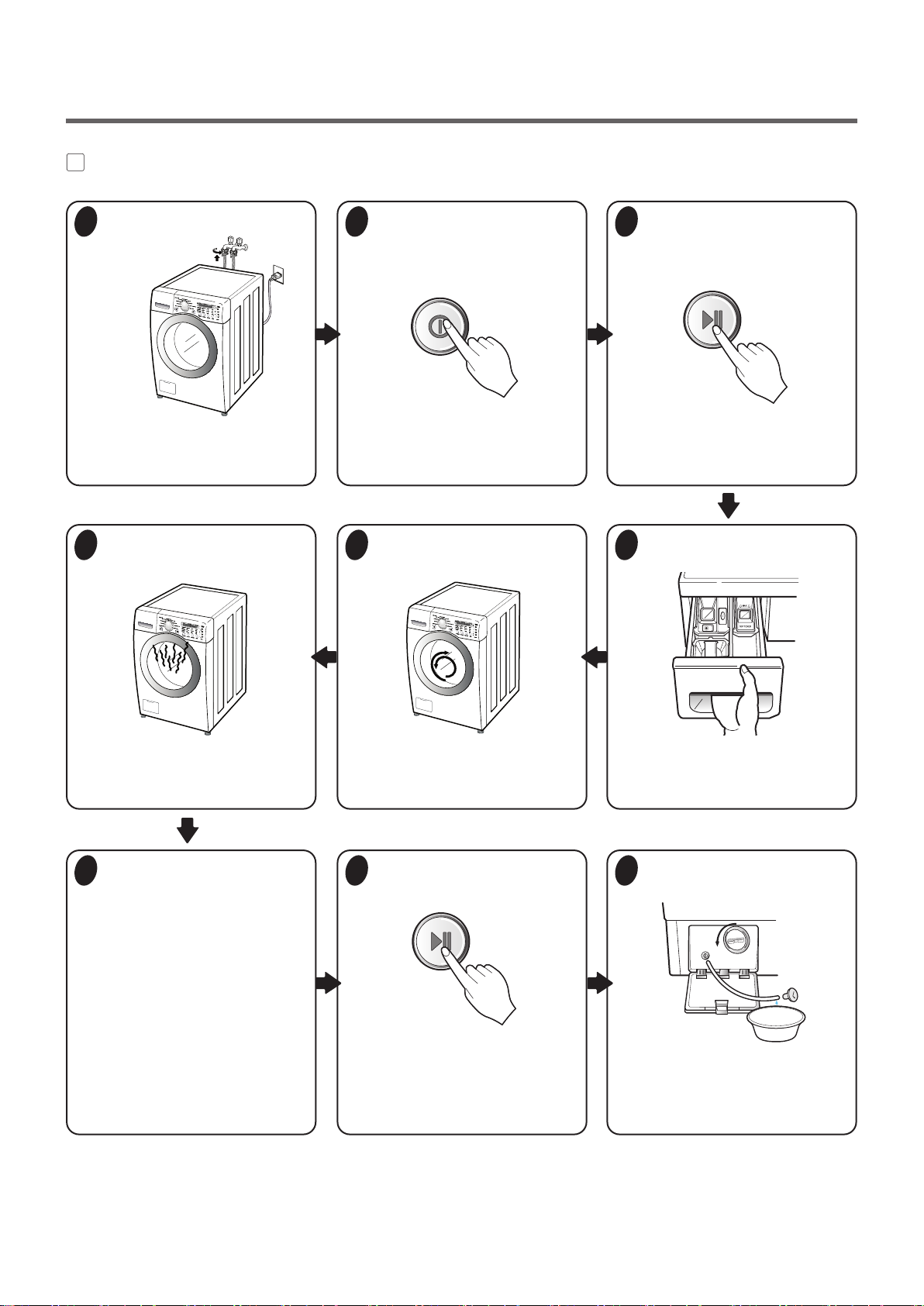

4. Installation and Test ................................................................................................................... 8-10

5. Operation ................................................................................................................................. 11-17

5-1. Control Panel Features ..................................................................................................... 11-13

5-2. Cycle Guide ........................................................................................................................... 14

5-3. Special Functions ................................................................................................................... 15

5-4. Explanation of Each Process ............................................................................................ 16-17

6. Test Mode ...................................................................................................................................... 18

6-1. Safety Caution ....................................................................................................................... 18

6-2. Load Test Mode ..................................................................................................................... 18

6-3. How To Read the Display in Load Test Mode ........................................................................ 18

7. Troubleshooting ............................................................................................................................ 19

7-1. Safety Caution ....................................................................................................................... 19

7-2. Error Mode Summary ....................................................................................................... 19-20

7-3. Troubleshooting With Error ............................................................................................... 21-27

7-5. Before using the Tag On function .......................................................................................... 33

7-4. Troubleshooting Else ........................................................................................................ 28-32

8. Component Testing Information .................................................................................................... 34

8-1. Filter Assembly (Line Filter) ................................................................................................... 34

8-2. Door Look Switch Assembly ............................................................................................. 35-36

8-3. Stator Assembly ................................................................................................................ 37-39

8-4. Pump Motor Assembly ........................................................................................................... 40

8-5. Inlet Valve Assembly .............................................................................................................. 41

8-6. Heater Assembly .................................................................................................................... 42

8-7. Thermistor Assembly ........................................................................................................ 43-44

9. Disassembly Instructions ........................................................................................................... 45-53

10. Exploded View ......................................................................................................................... 54-56

11. Wiring Diagram ............................................................................................................................. 57

10-1. Cabinet and Control Panel Assembly ................................................................................... 54

10-2. Drum and Tub Assembly ...................................................................................................... 55

10-3. Dispenser Assembly ............................................................................................................. 56