8

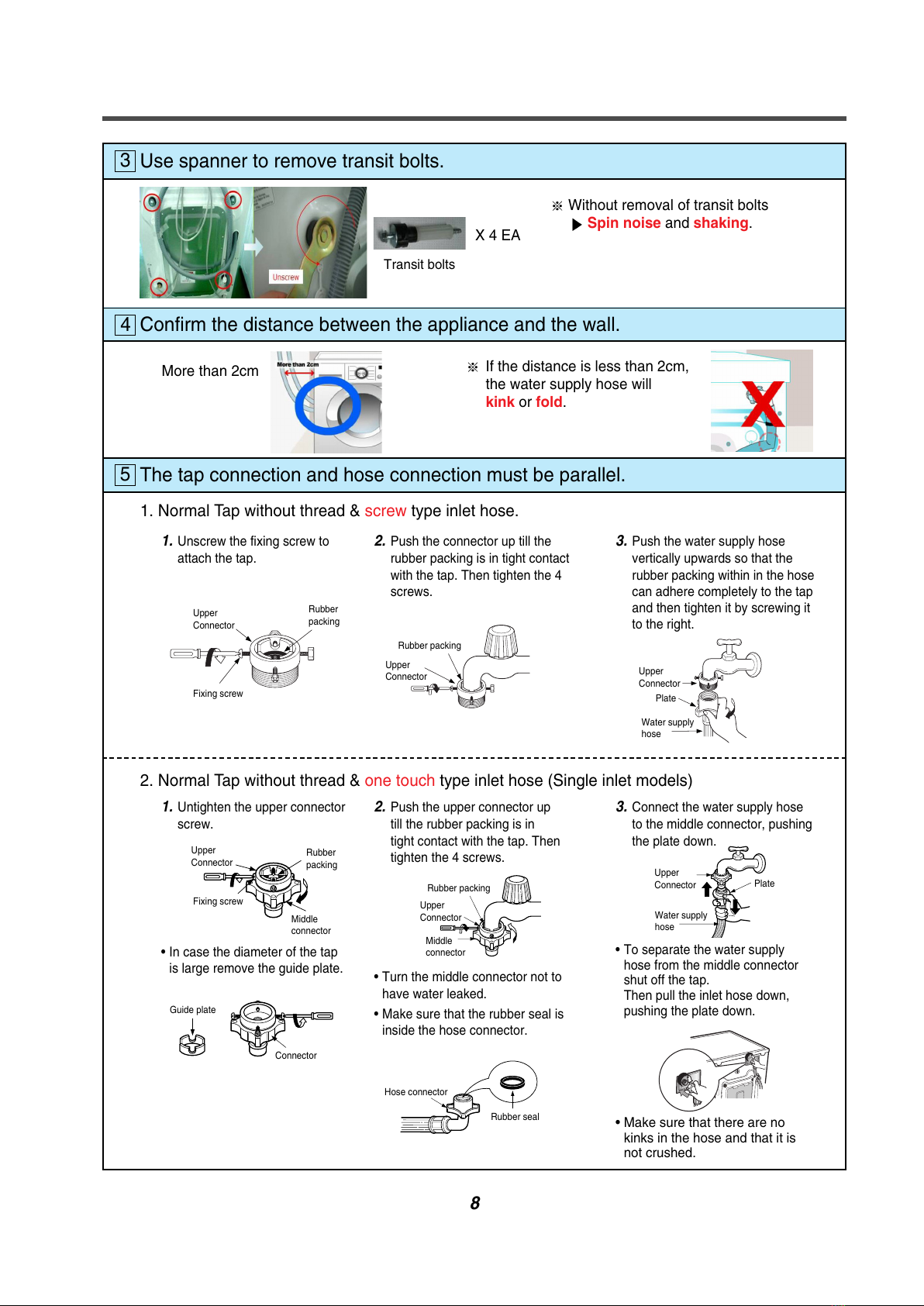

Use spanner to remove transit bolts.

3

Confirm the distance between the appliance and the wall.

4

The tap connection and hose connection must be parallel.

5

Without removal of transit bolts

Spin noise and shaking.

X 4 EA

Transit bolts

More than 2cm If the distance is less than 2cm,

the water supply hose will

kink or fold.

1. Normal Tap without thread & screw type inlet hose.

1. Unscrew the fixing screw to

attach the tap.

2. Push the connector up till the

rubber packing is in tight contact

with the tap. Then tighten the 4

screws.

3. Push the water supply hose

vertically upwards so that the

rubber packing within in the hose

can adhere completely to the tap

and then tighten it by screwing it

to the right.

1. Untighten the upper connector

screw.

2. Push the upper connector up

till the rubber packing is in

tight contact with the tap. Then

tighten the 4 screws.

3. Connect the water supply hose

to the middle connector, pushing

the plate down.

•In case the diameter of the tap

is large remove the guide plate. •Turn the middle connector not to

have water leaked.

•Make sure that the rubber seal is

inside the hose connector.

•To separate the water supply

hose from the middle connector

shut off the tap.

Then pull the inlet hose down,

pushing the plate down.

•Make sure that there are no

kinks in the hose and that it is

not crushed.

2. Normal Tap without thread & one touch type inlet hose (Single inlet models)

Upper

Connector

Fixing screw

Guide plate

Connector

Rubber packing

Upper

Connector

Rubber packing

Upper

Connector Plate

Water supply

hose

Rubber seal

Hose connector

Upper

Connector

Middle

connector

Rubber

packing

Upper

Connector

Fixing screw

Middle

connector

Rubber

packing

Upper

Connector

Plate

Water supply

hose