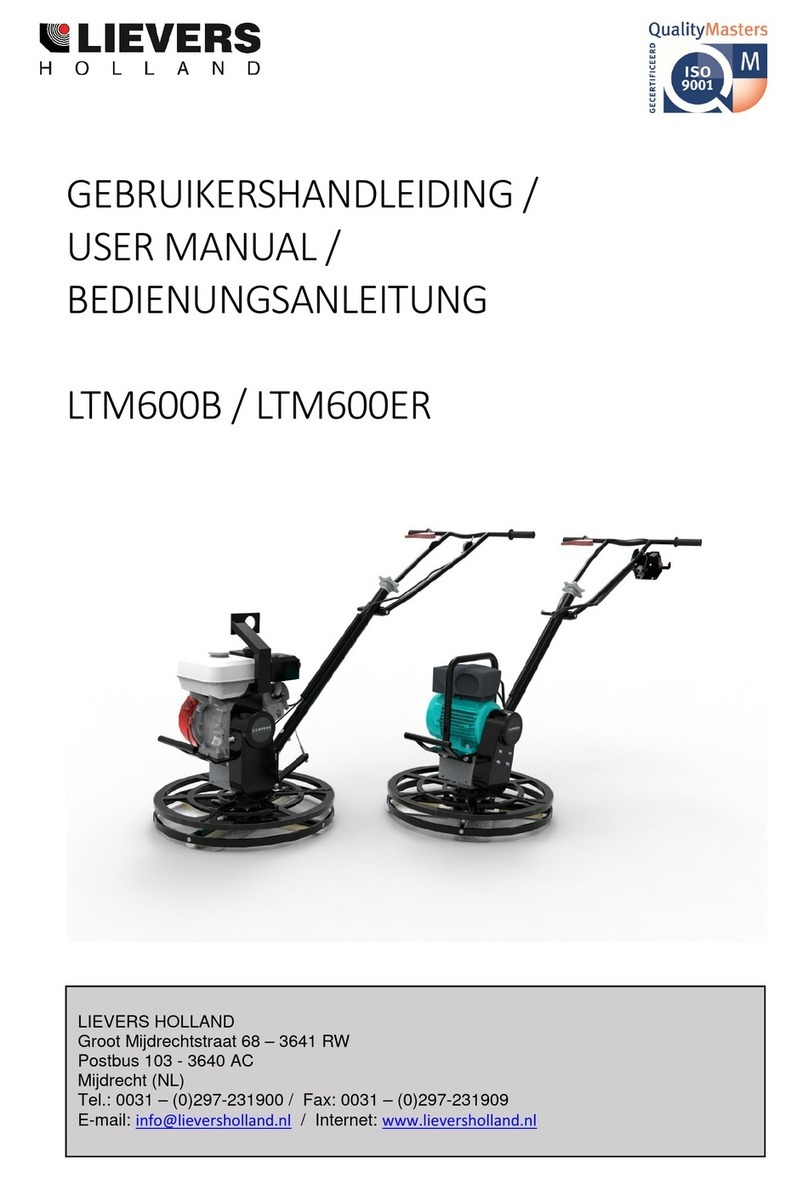

HAL Operation manual

- Check the feeder cable’s outercasing and if in use extension lead’s outercasing before you connect

the machine to the electrical mains. The outercasing may not be damaged. Replace the cable if

you cannot read the marks on the outercasing anymore.

- Check the machine’s cable-connections before you connect the machine to the electrical mains.

The cables must be properly connected.

- Switch off the machine, when the electrical power cuts off. This prevents the machine from starting

suddenly when the electrical power comes on again.

- Disconnect the electrical supply to the machine, before you start to clean or maintain the machine.

- Ensure that the ventilation slots of the machine are free from dirt and moisture.

The following safety-aspects specifically apply to those Lievers products which

are equipped with a petrol-engine.

- Do not use the Bullfloat with petrol-engine indoors or in poorly ventilated places, such as pits etc.

- Make sure that there is sufficient ventilation in spaces which are surrounded by walls. Never inhale

exhaust gasses, they can damage your health and that of your colleagues.

- To avoid getting an electric shock, do not touch the high-tension cable or spark plug cap while the

engine is running.

- Check for fuel leaks before running the machine.

- Do wear working-gloves, safety glasses and protecting clothing during refueling.

- Make sure that there is sufficient ventilation during refueling.

- Refueling of fuel is only allowed after the engine has been cooled off sufficiently.

- Refueling of fuel , while the engine is hot, might lead to a very dangerous situation.

It is strictly forbidden to refuel :

* in the direct vicinity of open fire or other flammable materials,

* while smoking cigarettes etc.

* in explosion endangered spaces.

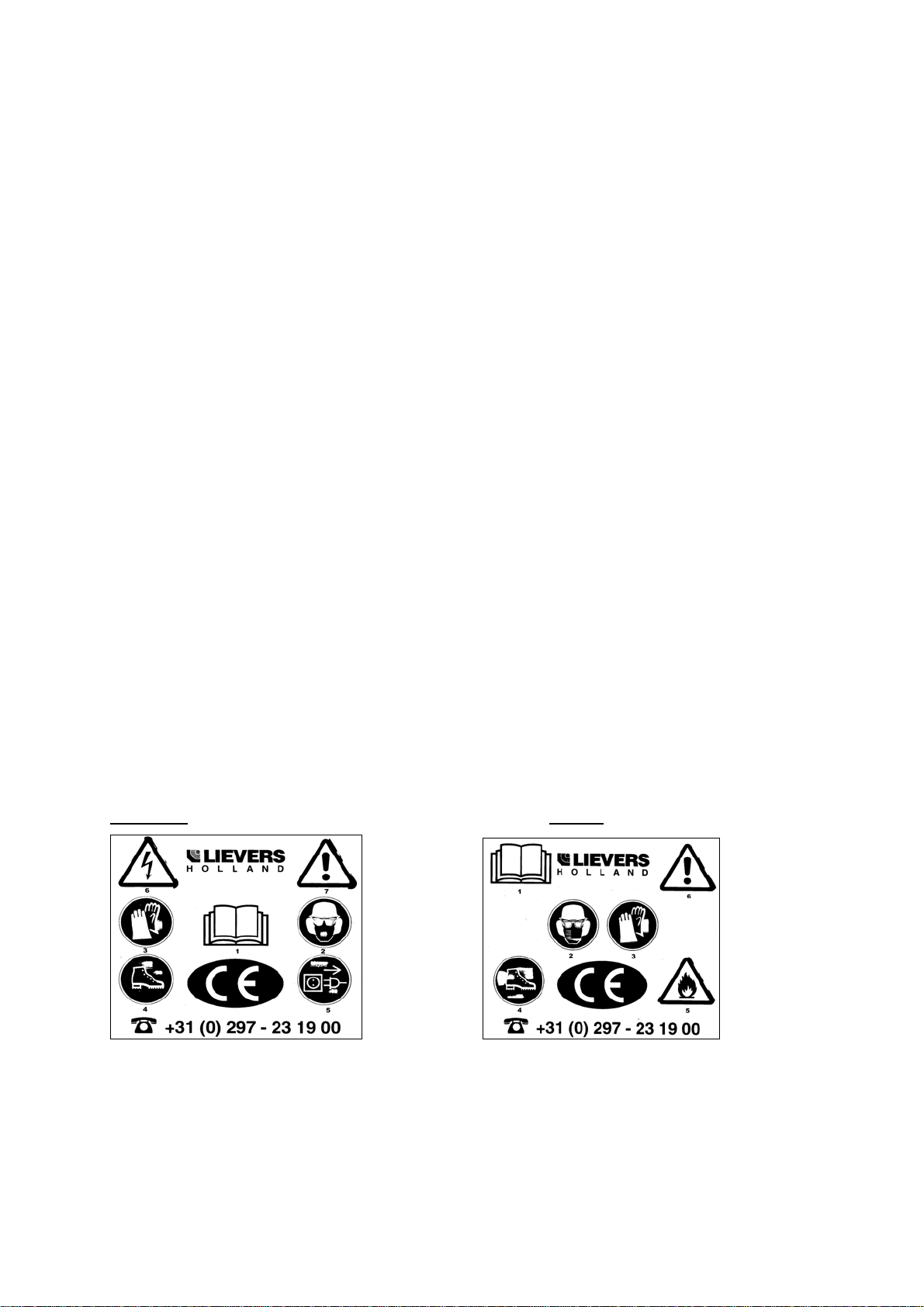

Explanation of the used safety symbols

HAL E/ER HAL B

1 Please read the instructionbook

2 Safety glasses, safety helmet and ear protection compulsory.

3 Working gloves compulsory. (vibration Isolating work Glove with GELFÔM)

4 Safety shoes with extra protection compulsory.

5 Before opening the motorhousing remove the plug from the mains/ Inflammable material

6 Dangerous electrical voltage/ Careful, DANGER!

7 Careful, DANGER!!

TIP: If the safety aspects are not clear to you, then please contact the manufacturer for

further information: Lievers Holland. Telephone: + 31 297 231900; Telefax: + 31 297 231909

4