2(13)

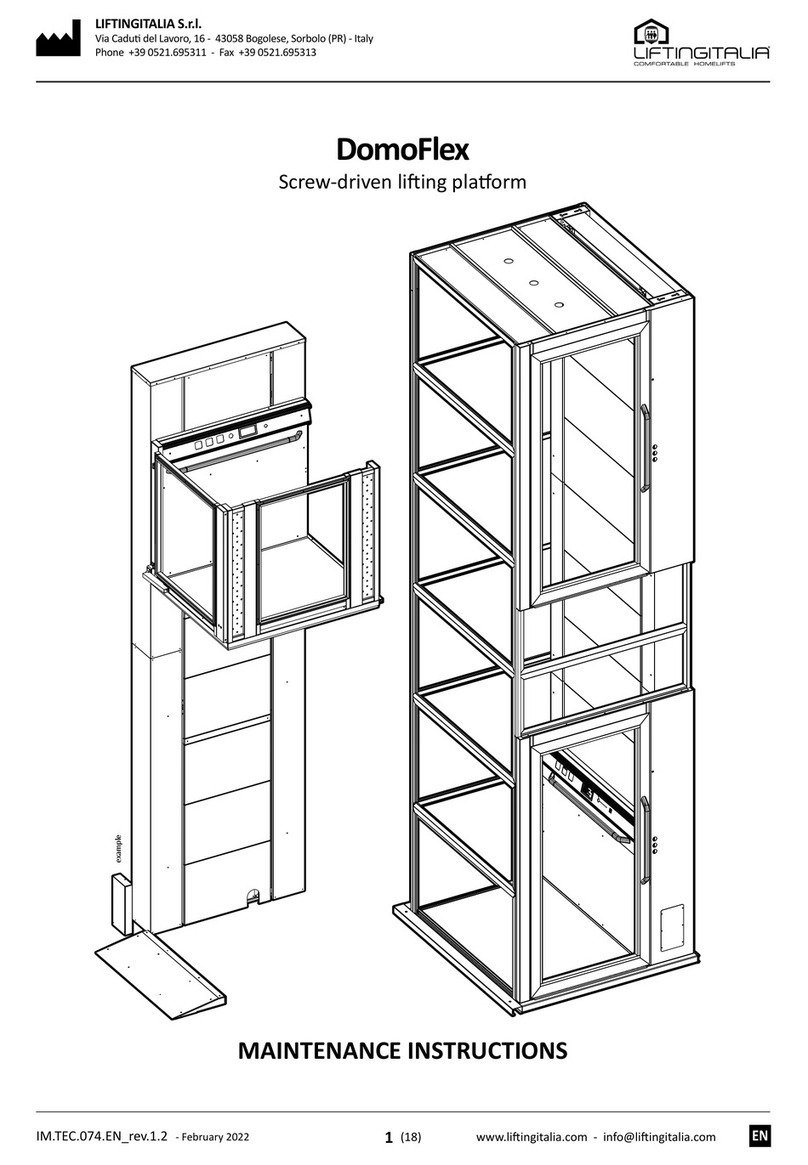

inDOMO HP - Plaorm li

FINAL TESTS

IM.TEC.028.EN_rev.10.2 - November 2015 All rights reserved

10.2 General update 30.11.2015

10.1 Update pages 5, 8 27.02.2014

10 General update and new layout 30.01.2013

Rev. Descrizione Data

INDEX

As far as the following items are concerned : general instrucons, safety instrucons,

responsibility and warranty, material receiving and storage on site, packing, waste disposal,

cleaning and maintenance, please consult the manual "SAFETY AND MATERIAL HANDLING

ON SITE".

0 MANUAL READING GUIDE ................................................................................................................ 3

0.1 CHAPTER SYMBOLS.......................................................................................................................3

0.2 IMPORTANT ITEMS .......................................................................................................................3

0.3 INDIVIDUAL SAFETY DEVICES...............................................................................................................3

1 COMMISSIONING AND HANDOVER........................................................................................................ 4

2 CONFORMITY TESTS ..................................................................................................................... 4

2.1 CONTROL PANEL TESTING .................................................................................................................5

2.2 FIRST TEST TRAVELS ......................................................................................................................5

2.3 SAFETY BRAKES TESTING ..................................................................................................................5

2.4 ORIGINAL MATERIALS FROM LIFTINGITALIA ..................................................................................................5

2.5 STRUCTURAL TEST........................................................................................................................5

2.6 MAXIMUM STATIC PRESSURE ..............................................................................................................5

2.7 HYDRAULIC CIRCUIT ......................................................................................................................5

2.8 BLOCK VALVE ............................................................................................................................5

2.9 OVERLOAD MANOSTAT ...................................................................................................................6

2.10 ASCENT AND DESCENT SPEED..............................................................................................................6

2.11 STOP PRECISION .........................................................................................................................6

2.12 SAFETY SPACE IN PIT ......................................................................................................................6

2.13 “STOP” (if present ) AND ALARM BUTTONS..................................................................................................7

2.14 EMERGENCY POWER SUPPLY ..............................................................................................................7

2.15 SHAFT CLOSURE..........................................................................................................................7

2.16 COMMANDS ............................................................................................................................7

2.17 CEILING CONTACT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.18 COP CONTACT ...........................................................................................................................7

2.19 OVERRUN CONTACT AND HEADROOM SPACER ...............................................................................................8

2.20 LANDING DOOR LOCKS....................................................................................................................8

2.21 DISTANCES FROM THE ENTRANCE ..........................................................................................................8

2.22 CAR LEVELLING DISTANCE .................................................................................................................8

2.23 CAR LEVELLING ..........................................................................................................................8

2.24 MANUAL PUMP..........................................................................................................................9

2.25 OVERPRESSURE VALVE TEST ...............................................................................................................9

2.26 PULLEY SAFETY COVERS ...................................................................................................................9

2.27 GUIDE BRACKETS CENTER TO CENTER DISTANCE..............................................................................................9

2.28 GROUNDING CONNECTION................................................................................................................9

2.29 ELECTRICAL COMPONENTS INSULATION.....................................................................................................9

2.30 SHAFT LIGHTING AND SOCKET (if any).......................................................................................................9

2.31 PHOTOCELLS OR LIGHT BARRIERS (if any) ...................................................................................................10

2.32 BUTTON ENABLING KEY (oponal).........................................................................................................10

2.33 CONTROL CABINET ......................................................................................................................10

2.34 SIGNAGE ...............................................................................................................................10

2.35 NOISE EMISSION ........................................................................................................................10