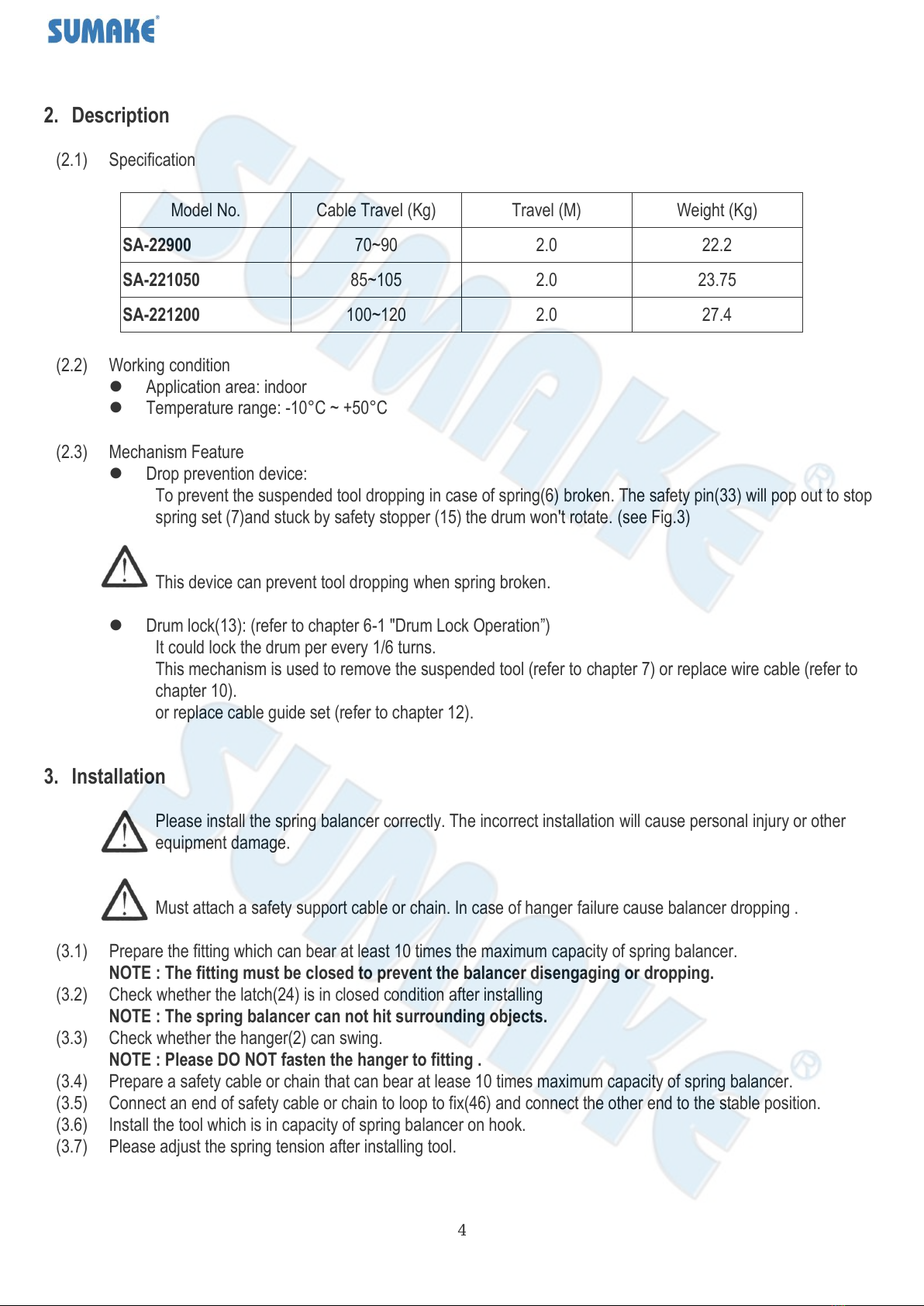

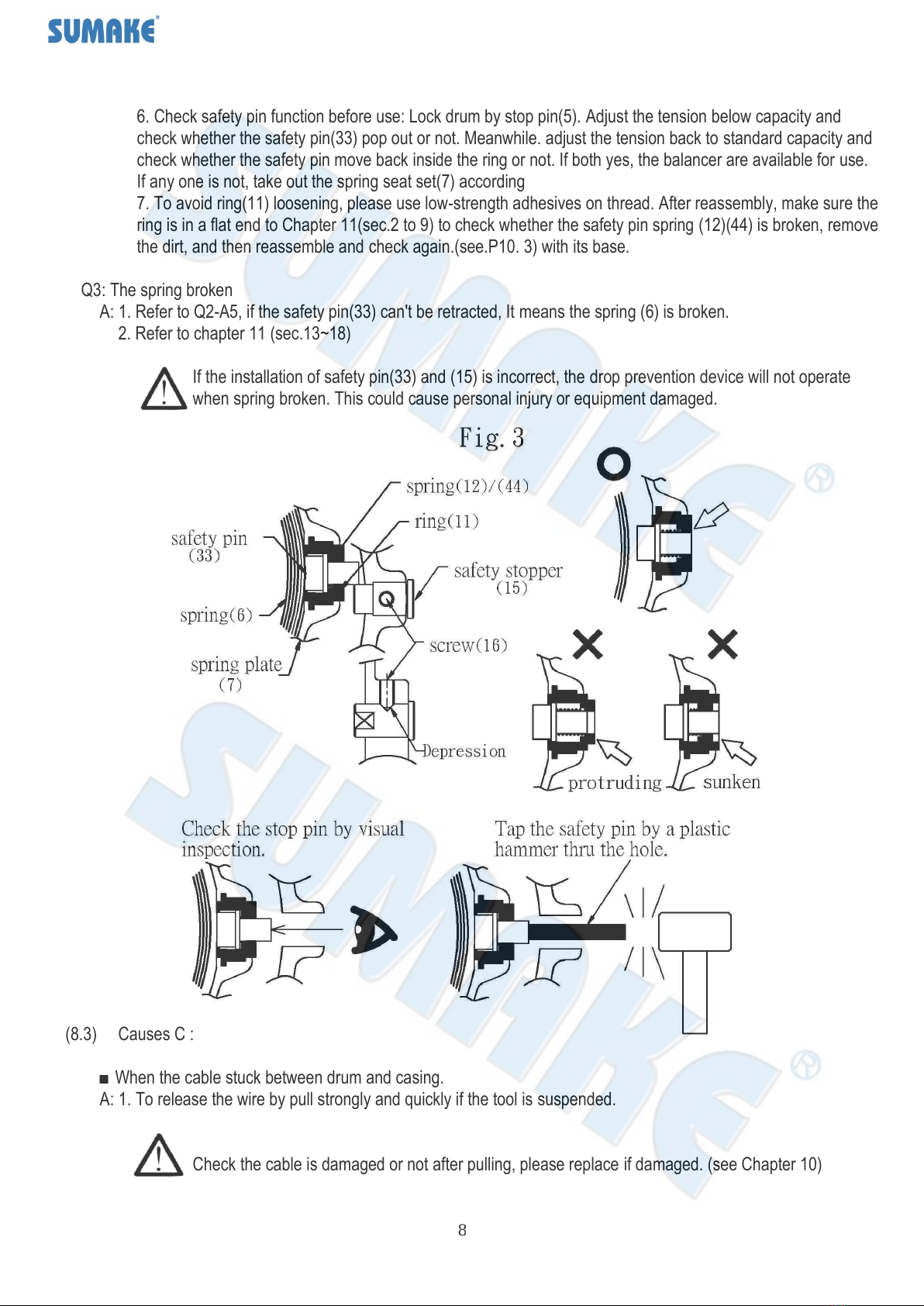

6. Drum Lock Operation(5)(see Fig.1)

(6.1) Pull the stop pin (No.13) and turn clockwise to lock position And move the tool upward or downward until drum

become locked.

(6.2) Move the tool again to check the drum is locked securely then remove tool from hook.

Please check whether the stop pin is in lock position before removing suspended tool. The cable only

can move around 3~5 mm .(see Fig.1)

If the drum is not in lock position then the cable will retract back immediately and may cause personal

injury.

(6.3) If drum lock activate with cable pull out, please attach suitable weight tool before releasing drum lock.

(6.4) Please pull the stop pin (No.13) up then turn counter-clockwise then place it in open position. (see Fig.1)

Please DO NOT release drum lock if spring balancer unload or the weight of new tool is different with

old tool.

If release it, the cable will retract back immediately or the tool will drop down to cause personal injury.

For safety consideration, please adjust spring tension to fit suspended tool before releasing drum lock.

7. Tool/device Replacement

Method No.1--Replace tool by drum lock (13)

1. According chapter 6 "Drum Lock Operation", operator can remove suspended tool when stop pin in lock potion.

The operator can move tool upward and downward to check drum is locked securely.

If drum is not locked securely, the cable will retract back immediately and cause personal injury.

2. Please check the weight of new tool with all accessories is in capacity of spring balancer before attaching.

3. Please use wrench to adjust spring tension by turning worm gear. Turn clockwise is to increase (+) spring tension;

turn counterclockwise is to reduce (-) spring tension and the gauge will show current approximate spring tension.

(see P5, Fig.2)

4. Please release pin after attaching new tool.(see Fig.1)

Please DO NOT release drum lock before adjusting spring tension, if spring balancer unload or the

weight of new tool is different with old tool. If release it, the cable will retract back immediately or the

tool will drop down to cause personal injury.

5. Please re-adjust the spring tension after attaching new tool .

NOTE : Setting spring tension over maximum capacity may cause spring balancer or cable set damaged

Method No.2--Replace tool without locking drum (5)

Never remove suspended tool when cable is extended. Or the cable will retract back immediately to

cause personal injury.