English English

5

CYLINDER MAY EXPLODE IF DAMAGED: Use only compressed gas cylinders containing the

correct shielding gas for the process used and properly operating regulators designed for the gas and

pressure used. Always keep cylinders in an upright position securely chained to a fixed support. Do

not move or transport gas cylinders with the protection cap removed. Do not allow the electrode,

electrode holder, work clamp or any other electrically live part to touch a gas cylinder. Gas cylinders

must be located away from areas where they may be subjected to physical damage or the welding

process including sparks and heat sources.

The manufacturer reserves the right to make changes and/or improvements in design without upgrade at the same time

the operator’s manual.

Introduction

LGA Interface is an add-on module intended to be used

with Lincoln Electric Arclink welders such as Power

WaveR450 and S500,. The module attaches to the

front of a machine in place of a User Interface. The

LGA Interface add-on contains a Lincoln Electric

L16616 Anybus board with an HMS Anybus

CompactCom M30 module.. LGA works as a gate

between an industrial network and the welder’s internal

Arclink network. It also works as the welding sequencer

for the welder and is capable of storing up to 1000

welding jobs. A welding job contains all necessary

welding parameters: from PostFlow, to Striking,

Ramping up, Welding, Ramping down, Crater fill,

Burnback operation, and Post Flow.

Configuration of the job can be done in one of two

different ways, using the LGA Control Panel or through

the Power Wave Manager software. The jobs are saved

on the L16616 board in the LGA Interface module.

When replacing a LGA Interface module or this board,

the Jobs should be backed up first, and then restored

when the new module/board is installed.

The LGA Interface is designed for ease of configure

and use with a PLC. There are two modes of operation,

Job Mode and Job Mode with Parameter Inputs. Each

of these modes of operation requires that 12 bytes of

data be sent to and from the Master to the welder. In its

simplest implementation, Job Mode, all that is required

to initiate welding is to send over a valid Job Number

and then to set the Trigger input bit to true. All the

welding parameters are contained from the Job setup

parameters. With Job Mode with Parameters Inputs, the

weld state inputs are obtained from IO inputs from the

PLC interface to the welder. In this mode of operation,

the Master has direct control of the weld state welding

parameters and these inputs parameters can be

changed during the weld.

LGA is designed to work in different welding

configurations. The LGA will control turn on and off the

Wire Drive motor and Gas output automatically during

the welding sequence.

Installation and Operator Instructions

Read this entire section before installation or operation

of the machine.

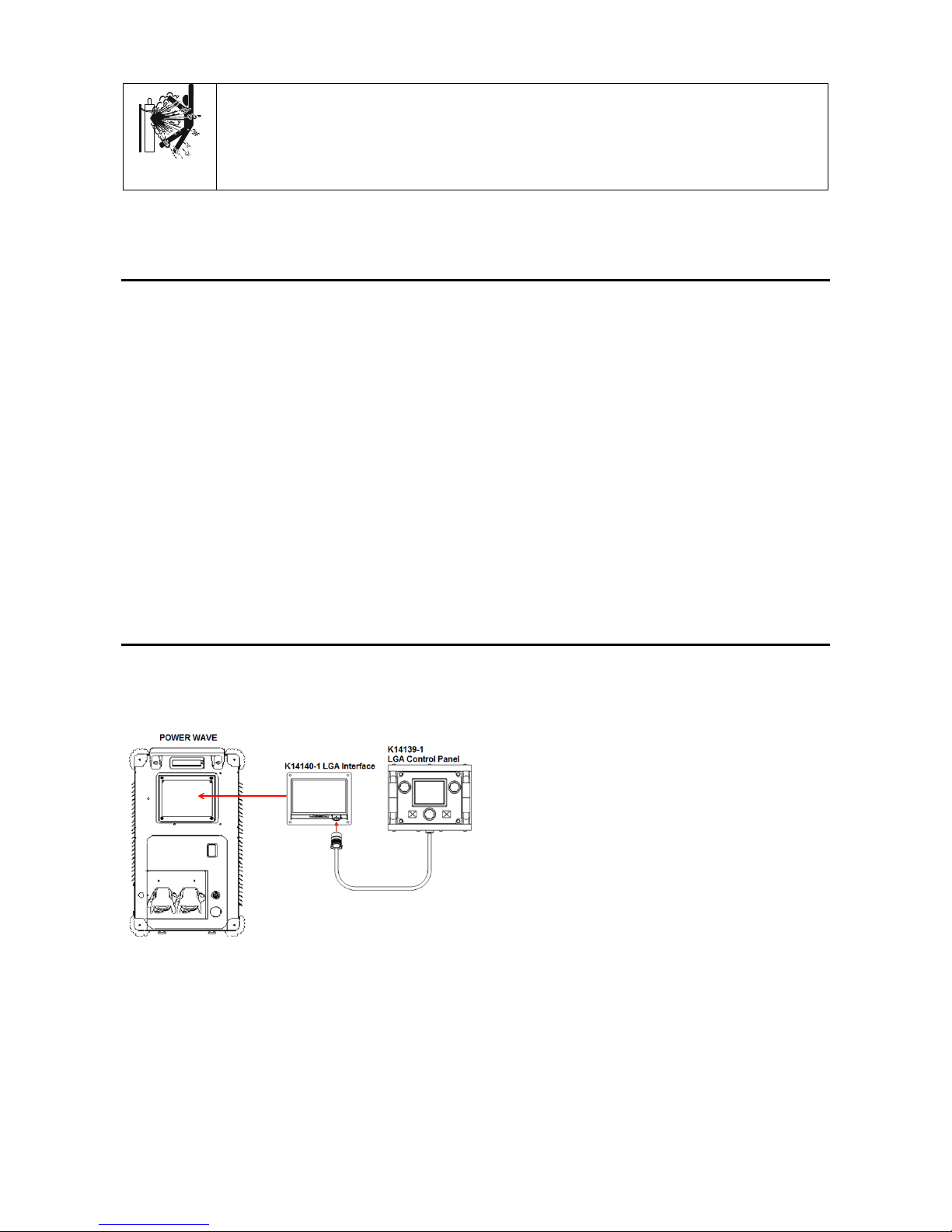

Connection Digram

Figure 1

Note: All welding parameters are stored in the LGA

Interface and it can work without LGA Control Panel

connected. It is recommended to connect/disconnect

LGA Control Panel when Power Source is switched off.

Connecting/disconnecting LGA Control Panel during

operation will stop welding process and restart the

system.

Requirements

A Robotic Wire Drive must be present or the Module

will go fatal with a 0x5211 (Required Object Not

Found), with an instance code of 1. A semi-

automatic wire drive will not work.

A Power Wave Control board (“G4800”, “G6683”, or

“L11088”) must be present or the Module will go

fatal with a 0x5211 (Required Object Not Found),

with an instance code of 2.

If an Autodrive SA or S is found, the Module will go

fatal with a 0x5611 (Arclink Bad Object).