10 Document #: LIN_EO_SM_DIGCT_S2500_DOM&INTL_4606010 – 07/21

Installation Section 2

Installation Requirements

DANGER

All utility connections and fixtures must be maintained in

accordance with local and national codes.

ELECTRICAL CODE REQUIREMENTS

nWarning

This appliance must be grounded and all field wiring

must conform to all applicable local and national

codes. Refer to rating plate for proper voltage. It is the

responsibility of the end user to provide the disconnect

means to satisfy the authority having jurisdiction.

nWarning

This equipment must be positioned so that the plug is

accessible unless other means for disconnection from

the power supply (e.g., circuit breaker or disconnect

switch) is provided.

,Caution

In order to avoid a hazard due to inadvertent resetting of

the thermal cutout, this appliance must not be supplied

through an external switching device, such as a timer or

connected to a circuit that is regularly switched on and

off by the utility.

IN USA: When installed, this appliance must be electrically

grounded and its installation must comply with the

National Electric Code, ANSI-NFPA 70, latest edition, the

manufacturers’installation instructions, and applicable local

municipal building codes.

IN CANADA: All electrical connections are to be made in

accordance with CSA C22.21 latest version – Canadian

Electrical Code Part 1 and/or local codes.

ALL OTHER COUNTRIES: Local electrical codes will prevail.

1. Strain relief is provided with each oven. International

Dealer/Distributors provide applicable power cord/

plug for each customer.

2. All pole disconnection switch must have 3 mm open

contact distance.

3. To prevent electrical shock, an equal potential bonding

ground lug is provided in the back. This allows the oven

to be connected to an external bonding system.

4. If used as double-stack and each oven has its own

disconnection switch, all switches should be close

together.

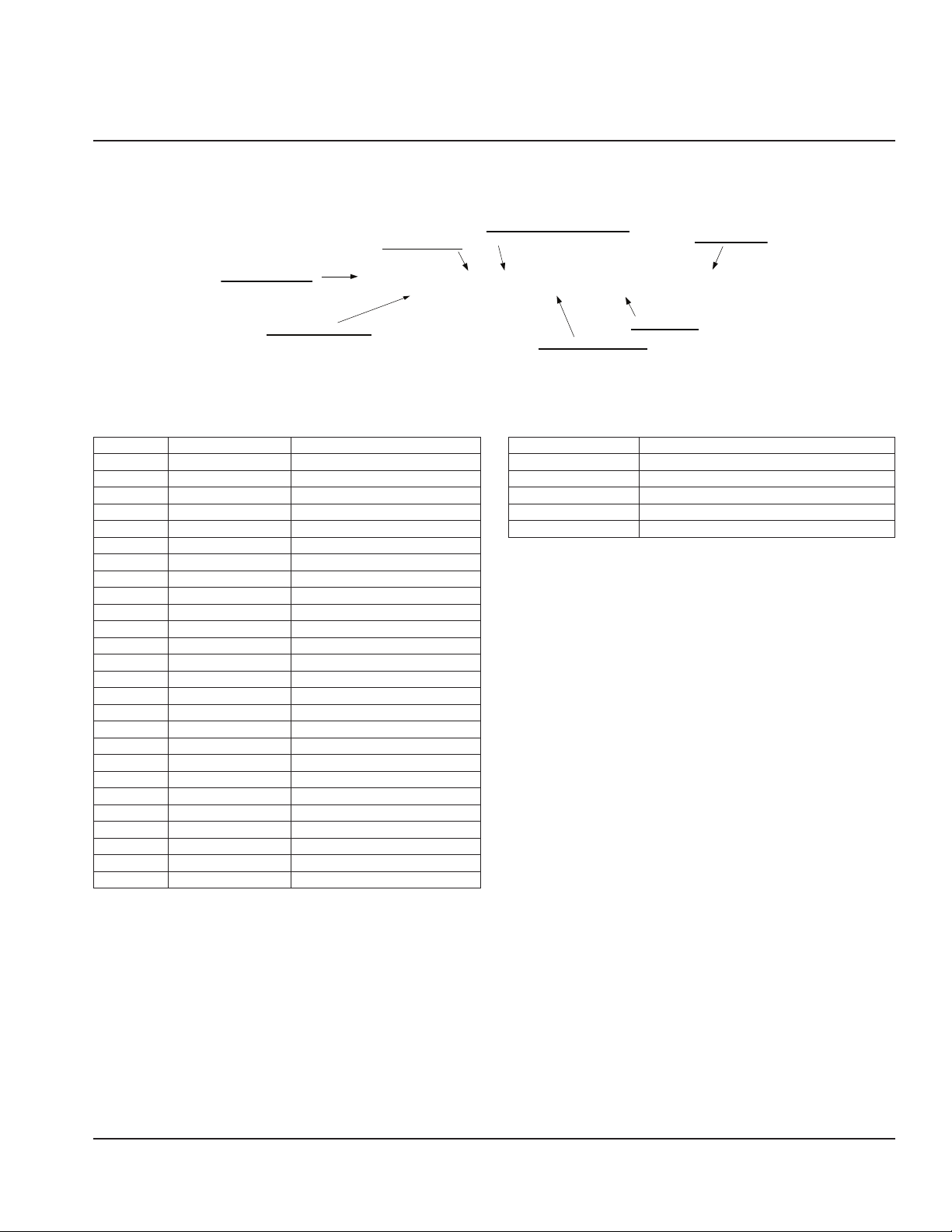

SPACING REQUIREMENTS

The oven must have 6 inches (152 mm) of clearance from

combustible surfaces. In case other equipment is located

on the right side of oven, a minimum clearance of 24 inches

(609 mm) is required from that equipment.

FOR ALL OVENS: A 24-inch (609 mm) clearance at the rear of

the oven must be obtainable for service access.

VENTILATION REQUIREMENTS

Local codes prevail. These are the authority having

jurisdiction as stated by the NATIONAL FIRE PROTECTION

ASSOCIATION, INC. in NFPA 96 latest edition.

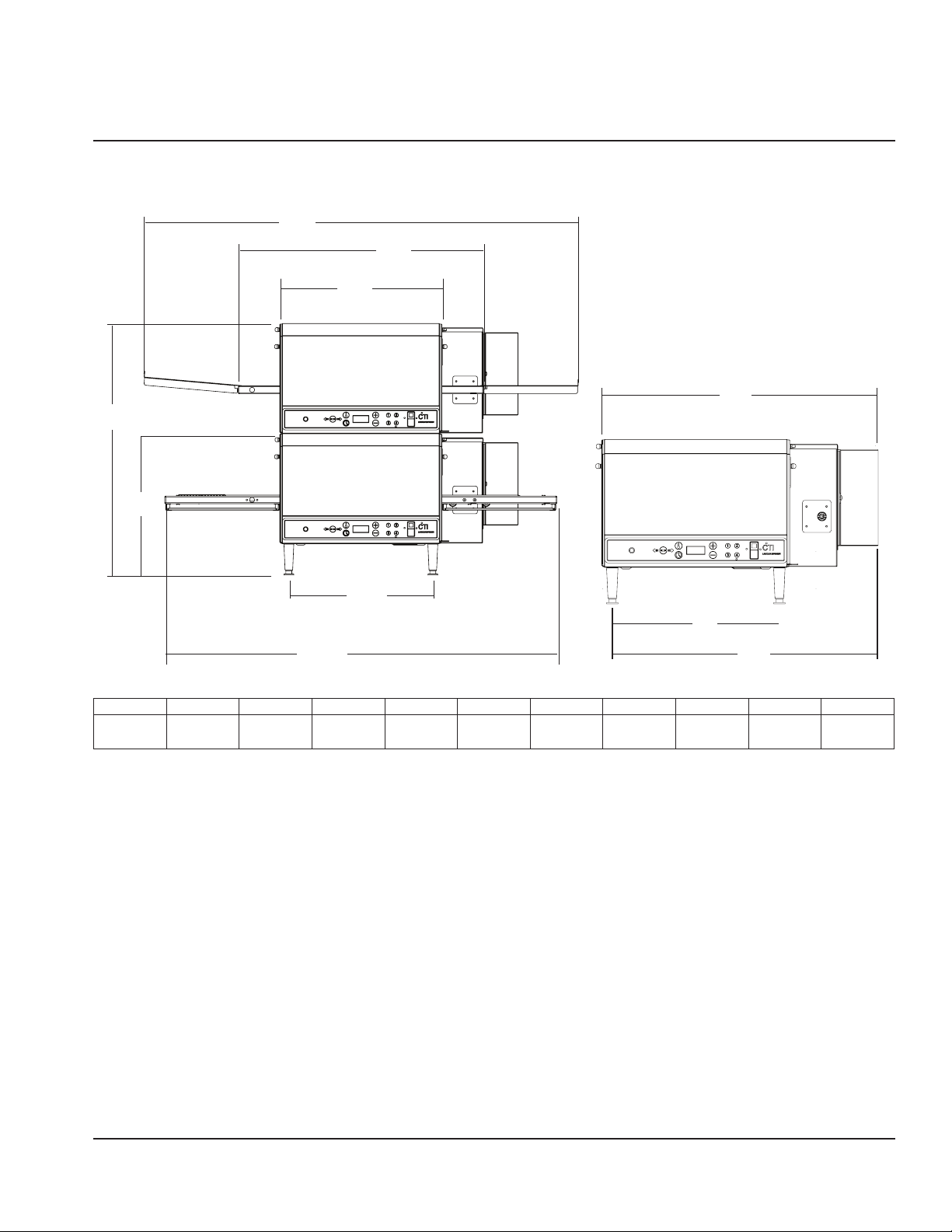

Installation

The instructions that follow are intended as a guide for

preparing for the installation of the Countertop Conveyor

oven. First and foremost, each crate should be examined

before signing the Bill of Lading to report any visible

damage caused during shipment in transit, and to account

for the proper number of crates.

IF THERE IS APPARENT DAMAGE:

UNITED STATES AND CANADA: Arrangements should

be made to file a claim against the carrier, as Interstate

Commerce Regulations require that the consignee initiate

a claim.

ALL SHIPMENTS TO OTHER COUTRIES: Freight terms will be

developed and extended on an individual basis.

Proper and secure storage facilities should be arranged for

the oven(s). If necessary, protect it from outdoor or damp

conditions at all times before installation.