2

Content

1 General Information 3

1.1 Operation Manual Information 3

1.2 Notes 3

1.3 Intended Use 3

1.4 Basic equipment 4

1.5 Transport 4

1.6 Information on disposal 4

1.7 Direction 4

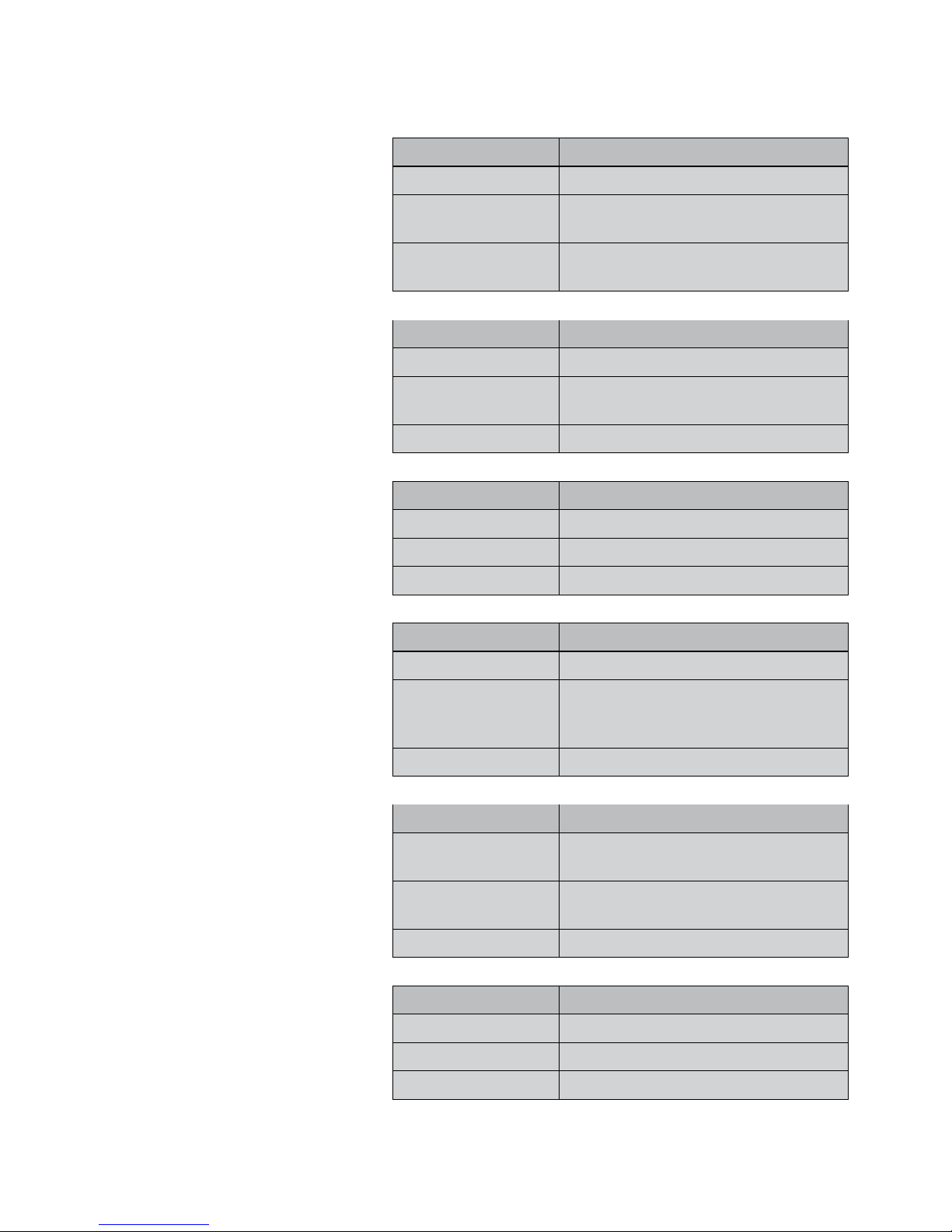

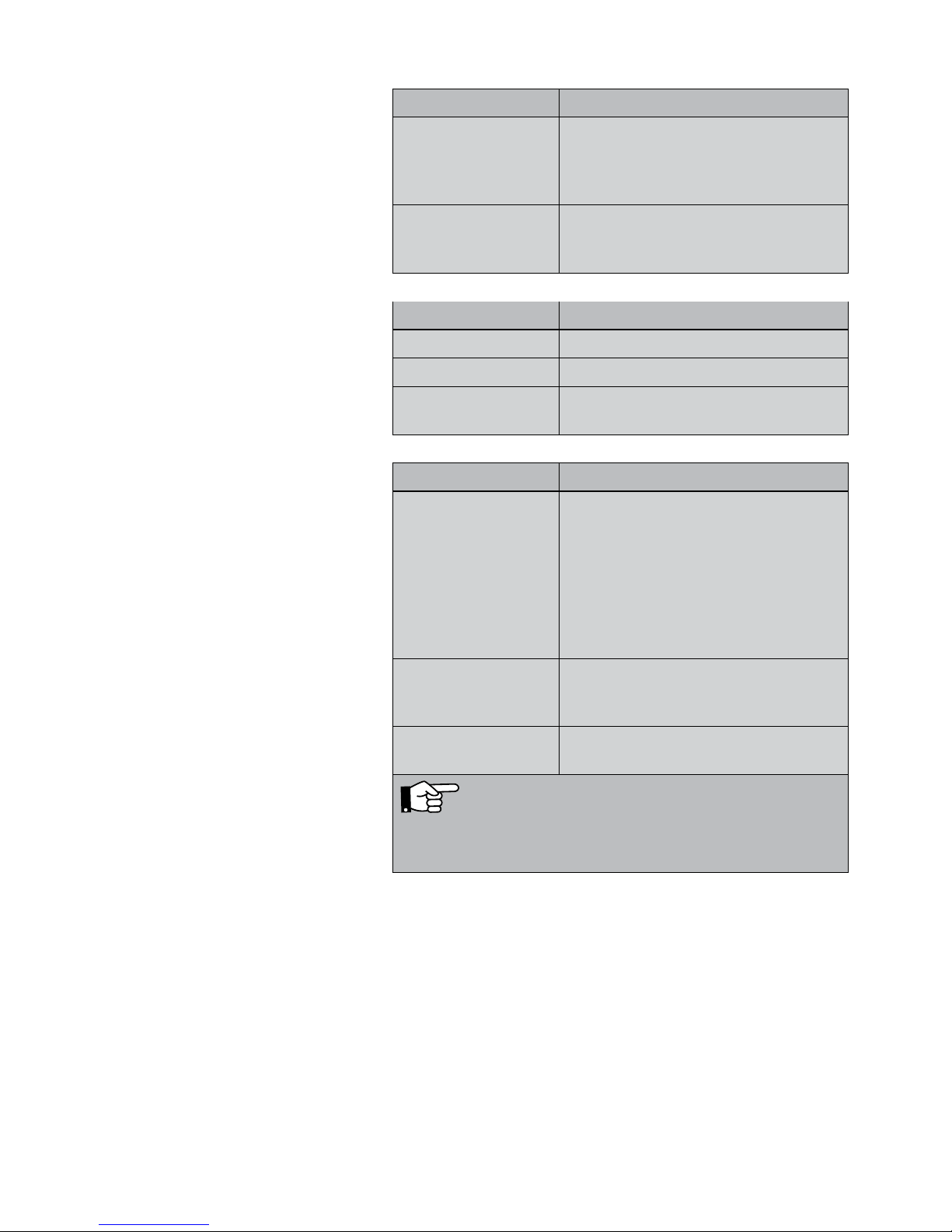

2 Specifications 5

2.1 Measured values 5

2.2 Calculated Values 6

2.3 Logger 6

2.4 Technical Data 7

3 Component explanation 8

3.1 Basic unit 8

3.2 Probes and Components 10

3.3 Function 12

3.4 Operating Mode 13

3.5 Display and key setup 13

4 Getting started 15

4.1 Check battery status 15

5 Operation 17

5.1 Turning the Meter on and Self Check 17

5.2 Measuring 17

5.3 Using the Pressure computer 18

6 Measurement modes 20

6.1 Selecting the main menu 20

6.2 Option “Air flow (k value)” 21

6.2.1 Theoretical background 21

6.2.2 Connecting the meter to the vent 23

6.2.3 Performing the Test 24

6.3 Option “K-Value Matching” 26

6.4 Option “Airflow (Pitot)” 28

6.4.1 Measuring the airflow (Pitot) 28

6.4.2 Grid-point measurements 29

6.5 Option “Air speed” 32

6.5.1 Measuring the air speed 32

6.5.2 Theoretical background 32

6.6 Option “4 PA Test” 34

6.7 Option “Heating Check” (Energy

Utilization Check) 37

6.8 Option „Volume“ 42

6.9 Option “U-value” 45

6.10 Option “Graph / Record” 46

6.11 Option „Print“ 48

6.12 Option "Setup" 47

6.13 Option "Save measurements" 49

7 Option 'Data management' 50

7.1.1 Save Customer Records 50

7.1.2 Creating a New Customer Folder 51

7.2 Option "Data management" 51

7.3 Data Transfer with the Computer or

Notebook 52

7.4 Data Logging 52

8 Troubleshooting 52

9 Maintenance 53

9.1 Maintenance work 53

10 Warranty and Service 53

10.1 Warranty 53

11 Accessories 54

12 Declaration of conformity 55