10

LTC3736

3736fa

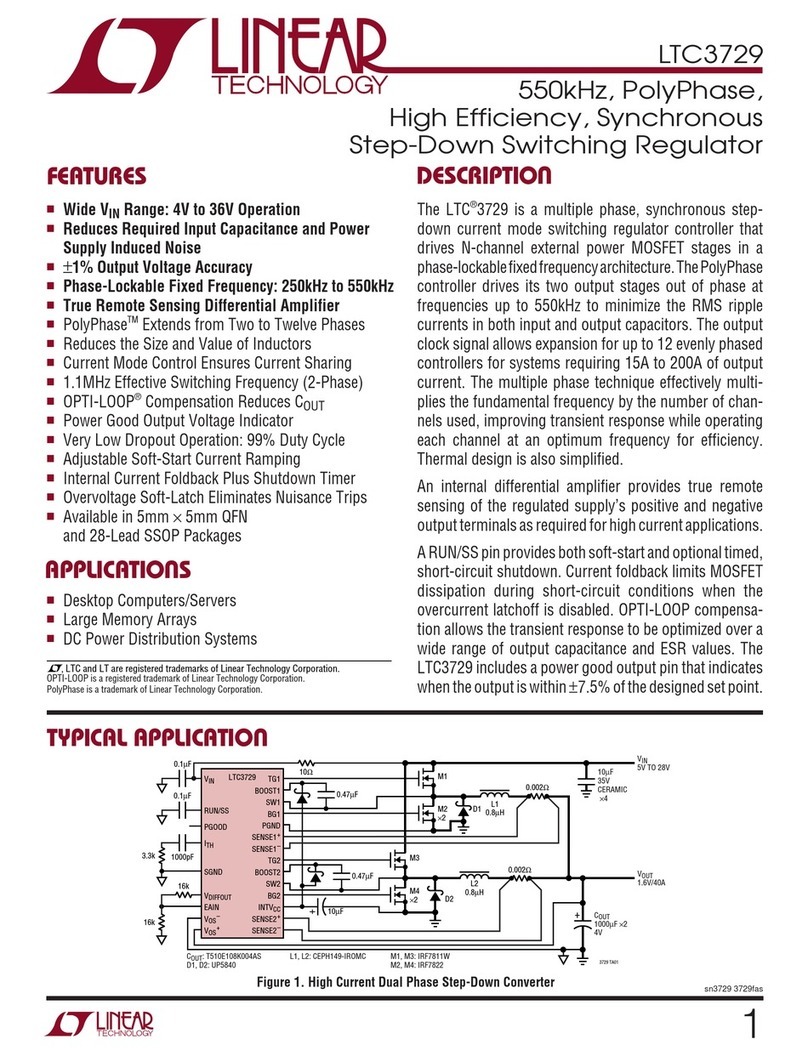

Main Control Loop

The LTC3736 uses a constant frequency, current mode

architecture with the two controllers operating 180 de-

grees out of phase. During normal operation, the top

external P-channel power MOSFET is turned on when the

clock for that channel sets the RS latch, and turned off

when the current comparator (I

CMP

) resets the latch. The

peak inductor current at which I

CMP

resets the RS latch is

determined by the voltage on the I

TH

pin, which is driven

by the output of the error amplifier (EAMP). The V

FB

pin

receives the output voltage feedback signal from an exter-

nal resistor divider. This feedback signal is compared to

the internal 0.6V reference voltage by the EAMP. When the

load current increases, it causes a slight decrease in V

FB

relative to the 0.6V reference, which in turn causes the I

TH

voltage to increase until the average inductor current

matches the new load current. While the top P-channel

MOSFET is off, the bottom N-channel MOSFET is turned

on until either the inductor current starts to reverse, as

indicated by the current reversal comparator, I

RCMP

, or the

beginning of the next cycle.

Shutdown, Soft-Start and Tracking Start-Up

(RUN/SS and TRACK Pins)

The LTC3736 is shut down by pulling the RUN/SS pin low.

In shutdown, all controller functions are disabled and the

chip draws only 9µA. The TG outputs are held high (off)

and the BG outputs low (off) in shutdown. Releasing

RUN/SS allows an internal 0.7µA current source to charge

up the RUN/SS pin. When the RUN/SS pin reaches 0.65V,

the LTC3736’s two controllers are enabled.

The start-up of V

OUT1

is controlled by the LTC3736’s

internal soft-start. During soft-start, the error amplifier

EAMP compares the feedback signal V

FB1

to the internal

soft-start ramp (instead of the 0.6V reference), which rises

linearly from 0V to 0.6V in about 1ms. This allows the

output voltage to rise smoothly from 0V to its final value,

while maintaining control of the inductor current.

The 1ms soft-start time can be increased by connecting

the optional external soft-start capacitor C

SS

between the

RUN/SS and SGND pins. As the RUN/SS pin continues to

OPERATIO

U

rise linearly from approximately 0.65V to 1.3V (being

charged by the internal 0.7µA current source), the EAMP

regulates the V

FB1

proportionally linearly from 0V to 0.6V.

The start-up of V

OUT2

is controlled by the voltage on the

TRACK pin. When the voltage on the TRACK pin is less

than the 0.6V internal reference, the LTC3736 regulates

the V

FB2

voltage to the TRACK pin instead of the 0.6V

reference. Typically, a resistor divider on V

OUT1

is con-

nected to the TRACK pin to allow the start-up of V

OUT2

to

“track” that of V

OUT1

. For one-to-one tracking during start-

up, the resistor divider would have the same values as the

divider on V

OUT2

that is connected to V

FB2

.

Light Load Operation (Burst Mode or Continuous

Conduction) (SYNC/FCB Pin)

The LTC3736 can be enabled to enter high efficiency Burst

Mode operation or forced continuous conduction mode at

low load currents. To select Burst Mode operation, tie the

SYNC/FCB pin to a DC voltage above 0.6V (e.g., V

IN

). To

select forced continuous operation, tie the SYNC/FCB to a

DC voltage below 0.6V (e.g., SGND). This 0.6V threshold

betweenBurst Modeoperation andforcedcontinuous mode

can be used in secondary winding regulation as described

in the Auxiliary Winding Control Using SYNC/FCB Pin dis-

cussion in the Applications Information section.

When a controller is in Burst Mode operation, the peak

current in the inductor is set to approximate one-fourth of

the maximum sense voltage even though the voltage on

the I

TH

pin indicates a lower value. If the average inductor

current is lower than the load current, the EAMP will

decrease the voltage on the I

TH

pin. When the I

TH

voltage

drops below 0.85V, the internal SLEEP signal goes high

and both external MOSFETs are turned off.

In sleep mode, much of the internal circuitry is turned off,

reducing the quiescent current that the LTC3736 draws.

The load current is supplied by the output capacitor. As

the output voltage decreases, the EAMP increases the I

TH

voltage. When the I

TH

voltage reaches 0.925V, the SLEEP

signal goes low and the controller resumes normal

operation by turning on the external P-channel MOSFET

on the next cycle of the internal oscillator.

(Refer to Functional Diagram)