Linear Technology LTC6801 Quick setup guide

1

dc1469bf

DEMO MANUAL DC1469B

Description

LTC6801

Multicell Li-Ion Battery

Monitor

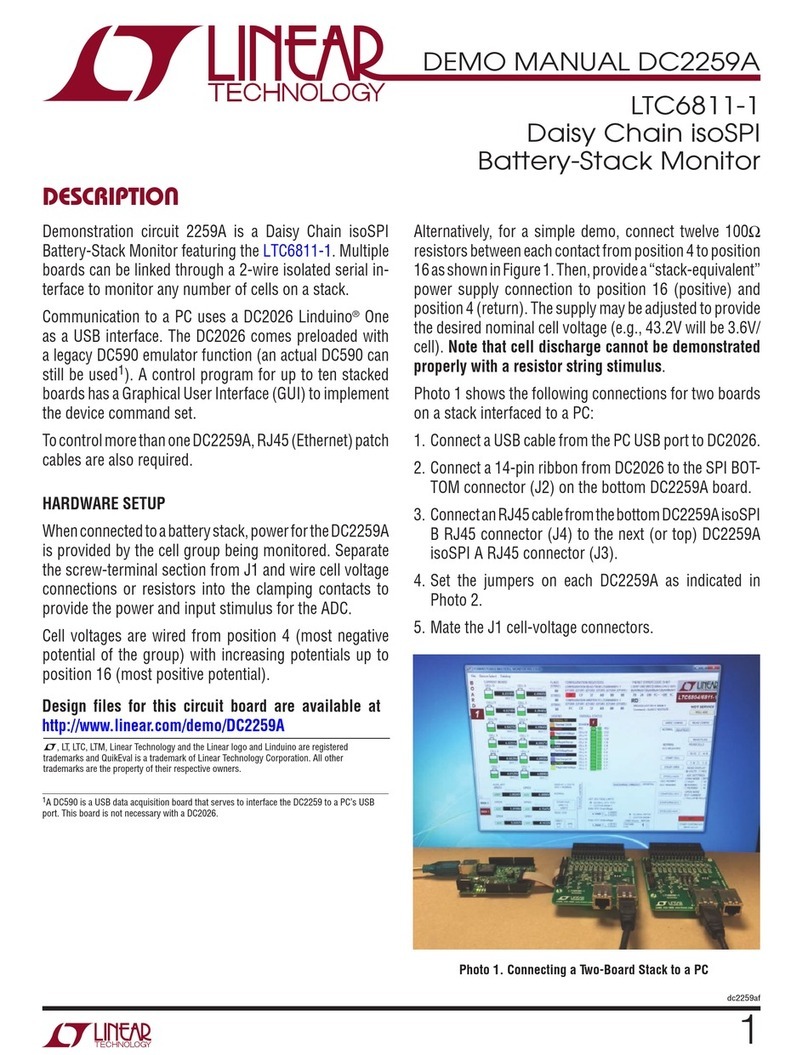

Demonstration circuit 1469B is a multicell Li-Ion battery

monitorfeaturingtheLT C

®

6801.Thiscircuitautonomously

detects individual over- and undervoltage conditions

on up to 12 series connected lithium-ion cells and two

temperature limits using suitable sensors. Pin-strapping

establishes the cell count to monitor, the threshold for

OV, threshold for UV, alarm hysteresis, and measurement

interval. A square wave is used to excite the alarm circuit,

and a returned signal duplicates this if no alarms are pres-

ent, but returns a static signal when a fault condition is

present. The circuit also provides a means of cascading

L, LT, LTC, LTM, Linear Technology and the Linear logo are registered trademarks of Linear

Technology Corporation. All other trademarks are the property of their respective owners.

performance summary

numerous monitors together so that very large series con-

nected arrays of cells can be monitored simultaneously.

Additional support features are provided on the demo

circuit, including a digital excitation source and an alarm

indicator LED, so that standalone evaluations can be per-

formed. Jumpers are provided to provide for local signal

loop back and to activate the desired support circuits.

The following table indicates the performance and control

ranges of the LTC6801.

Design files for this circuit board are available at

http://www.linear.com/demo/DC1469B

Specifications are at TA= 25°C

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

VIN Total Input Supply Range Total Potential of Series-Connected Cells 10 60 V

IQS Supply Current, Idle Current into V+Pin When Idle 30 µA

IMSupply Current, Measuring 15ms (Continuous)

130ms

500ms

700

200

90

µA

µA

µA

N Number of Cells Monitored 9 Strappable Choices 4 12 Cells

VUV Individual Cell Undervoltage Threshold 9 Strappable Choices 0.77 2.88 V

VOV Individual Cell Overvoltage Threshold 9 Strappable Choices 3.74 4.51 V

HYSUV Individual Cell Undervoltage Alarm Hysteresis 3 Strappable Choices 0 500 mV

HYSOV Individual Cell Overvoltage Alarm Hysteresis 0 200 mV

TCYCLE Measurement Cycle Time 3 Strappable Choices 15 500 ms

VERR Measurement Error –1 1 %

TEMPOP Operational Temperature Range –40 25 85 °C

TEMPLIM Temperature Alarm Limits (Nominal) Set by Onboard Thermistors –20 60 °C

FIN Alarm Enable Input Frequency Digital Square Wave 1 10 50 kHz

2

dc1469bf

DEMO MANUAL DC1469B

operating principles

The LTC6801 accepts a differential logic enable input EIN

and duplicates it on EOUT to drive a cascaded LTC6801

EIN port. A differential logic sense input SIN receives a

signal the same as EOUT (but usually from a cascaded

LTC6801) and performs a phase detection function. When

thephase detection finds a good correlation AND noalarms

are detected, the EIN signal propagates to the SOUT of the

LTC6801 and can drive the SIN port of an LTC6801 lower

in the cascade. For a single LTC6801, the EOUT signals are

simply looped back to the SIN port and the SOUT signal is

used to determine the alarm state. Logic signals passing

between cascaded LTC6802 devices are AC-coupled to

provide dielectric isolation. On the DC1469B, the coupling

is performed by 500V rated capacitors.

DC1469B provides an onboard 10kHz oscillator that can

be jumper configured to activate and drive the local EIN.

In a cascaded arrangement of demo circuits, only the

bottom-of-stack unit would be so configured, and only

in the event that an external stimulus wasn’t available.

The oscillator must be disabled to demonstrate minimum

power (i.e. in the idle condition).

An LED indicator circuit is also provided to allow visual

indication of the alarm condition. If activated by the jumper

configuration,the green indication shows thatall measure-

ments are within normal limits. Since the LED consumes

a few milliamperes, the feature should be disabled to

demonstrate lowest battery drain.

ConnectorsareprovidedtointerconnectmultipleDC1469B

boards in cascade. Ribbon cables perform the daisy chain,

and jumpers allow configuring the cascade connection as

a loop back for the top-of-stack unit.

3

dc1469bf

DEMO MANUAL DC1469B

Quick start proceDure

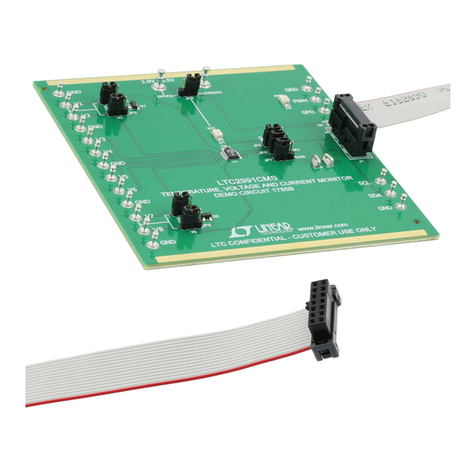

Demonstration circuit 1469B is easy to set up to evalu-

ate the performance of the LTC6801. Refer to Figure 1

for proper measurement equipment setup and follow the

procedure below:

1. Place jumpers in the following positions:

JP1 to JP5 GND position (horizontally)

JP6, JP7 VREG position (horizontally)

JP8 GND position (horizontally)

JP9 Both shunts in LOOP position (horizontally)

JP10 SE position

JP11 ON position

JP12 Both shunts in ON position (vertically)

2. J1 is a two-piece connector. The removable section

has the screw-clamp array, and may have been shipped

either mated, loose, or parked on the pass-through

fingers at the right edge of the board. This connector

allows for quick assembly of a wire harness to a cell

array (or cell array simulator). If such harnessing or

cell simulator has already been set up to work with

other Linear battery monitor demo circuits (DC1393B

for example), the movable part may be clamped to the

DC1469B battery pass-through fingers to form a simple

extender assembly. The harness connects to taps in

the cell array, supporting 4 to 12 cells of monitoring.

For cell counts less than 12, the topmost contact must

share a connection with the uppermost cell potential

of the group to properly power the LTC6801, and JP6

and JP7 reconfigured accordingly.

3. Turn on the power at the cell simulator, and adjust to

about 3V per cell (i.e. 36V for 12 cells).

NOTE: Make sure that the total input potential does not

exceed 60V. Individual cell potentials must not exceed

6V or protective Zener diodes will conduct.

4. The LED should illuminate, indicating that the monitor

is detecting nominal operating conditions. SOUT will

be a square wave like that furnished to EIN (SOUT/ is

the complement of SOUT).

5. Vary the cell simulator supply to see the alarm condi-

tion occur (LED dark and SOUT low). For the settings

given, thresholds are at about 9V and 45V for the total

12-cell potential. Refer to the data sheet and schematic

diagram (see Figure 2) for specific configurations of

other thresholds and parameters that may be of interest.

6. If multiple DC1469B assemblies are being evaluated,

they may be cascaded by attaching a ribbon from J3

to the J2 of another board. Board(s) with a ribbon at-

tached to J3 must have JP9 jumpers relocated to the

LINK position (horizontally). Board(s) with a ribbon

attached to J2 must have JP10 set to DIFF and JP12

jumpers in the OFF position (vertically) or removed.

7. To demonstrate standby power conditions, place both

JP12 jumpers to the OFF position (vertically) to inhibit

the enable clock. Supply current can be calculated

by the voltage drop on R13 (100Ω). Supply current

is somewhat dependant on the jumper configuration

strapping.

4

dc1469bf

DEMO MANUAL DC1469B

Quick start proceDure

Figure 1. Proper Evaluation Equipment Setup

5

dc1469bf

DEMO MANUAL DC1469B

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representa-

tion that the interconnection of its circuits as described herein will not infringe on existing patent rights.

schematic Diagram

6

dc1469bf

DEMO MANUAL DC1469B

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ●FAX: (408) 434-0507 ●www.linear.com

LINEAR TECHNOLOGY CORPORATION 2015

LT 0315 • PRINTED IN USA

DEMONSTRATION BOARD IMPORTANT NOTICE

Linear Technology Corporation (LT C ) provides the enclosed product(s) under the following AS IS conditions:

This demonstration board (DEMO BOARD) kit being sold or provided by Linear Technology is intended for use for ENGINEERING DEVELOPMENT

OR EVALUATION PURPOSES ONLY and is not provided by LT C for commercial use. As such, the DEMO BOARD herein may not be complete

in terms of required design-, marketing-, and/or manufacturing-related protective considerations, including but not limited to product safety

measures typically found in finished commercial goods. As a prototype, this product does not fall within the scope of the European Union

directive on electromagnetic compatibility and therefore may or may not meet the technical requirements of the directive, or other regulations.

If this evaluation kit does not meet the specifications recited in the DEMO BOARD manual the kit may be returned within 30 days from the date

of delivery for a full refund. THE FOREGOING WARRANTY IS THE EXCLUSIVE WARRANTY MADE BY THE SELLER TO BUYER AND IS IN LIEU

OF ALL OTHER WARRANTIES, EXPRESSED, IMPLIED, OR STATUTORY, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS

FOR ANY PARTICULAR PURPOSE. EXCEPT TO THE EXTENT OF THIS INDEMNITY, NEITHER PARTY SHALL BE LIABLE TO THE OTHER FOR

ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES.

The user assumes all responsibility and liability for proper and safe handling of the goods. Further, the user releases LT C from all claims

arising from the handling or use of the goods. Due to the open construction of the product, it is the user’s responsibility to take any and all

appropriate precautions with regard to electrostatic discharge. Also be aware that the products herein may not be regulatory compliant or

agency certified (FCC, UL, CE, etc.).

No License is granted under any patent right or other intellectual property whatsoever. LT C assumes no liability for applications assistance,

customer product design, software performance, or infringement of patents or any other intellectual property rights of any kind.

LT C currently services a variety of customers for products around the world, and therefore this transaction is not exclusive.

Please read the DEMO BOARD manual prior to handling the product. Persons handling this product must have electronics training and

observe good laboratory practice standards. Common sense is encouraged.

This notice contains important safety information about temperatures and voltages. For further safety concerns, please contact a LT C applica-

tion engineer.

Mailing Address:

Linear Technology

1630 McCarthy Blvd.

Milpitas, CA 95035

Copyright © 2004, Linear Technology Corporation

Table of contents

Other Linear Technology Monitor manuals