Linear Technology LTC6811-2 Quick setup guide

1

dc2260af

DEMO MANUAL DC2260A

DESCRIPTION

LTC6811-2

Addressable isoSPI Battery-

Stack Monitor

Demonstration circuit 2260A is an Addressable isoSPI

Battery-Stack Monitor featuring the LTC6811-2. Multiple

boards can be linked through a 2-wire isolated serial in-

terface to monitor any number of cells on a stack.

Communication to a PC uses a DC2026 Linduino

®

One

as a USB interface. The DC2026 comes preloaded with

a legacy DC590 emulator function (the DC590 can also

still be used1). A control program for up to ten stacked

boards has a Graphical User Interface (GUI) to implement

the device command set.

To control more than one DC2260A, the DC1941B isoSPI

adapterandRJ45(Ethernet) patch cables arealsorequired.

HARDWARE SETUP

When connected to a battery stack, power for the DC2260A

is provided by the cell group being monitored. Separate

the screw-terminal section from J1 and wire cell voltage

connections or resistors into the clamping contacts to

provide the input stimulus for the ADC.

Cell voltages are wired from position 4 (most negative

potential of the group) with increasing potentials up to

position 16 (most positive potential).

L, LT, LTC, LTM, Linear Technology and the Linear logo and Linduino are registered

trademarks and QuikEval is a trademark of Linear Technology Corporation. All other

trademarksare the property of their respective owners.

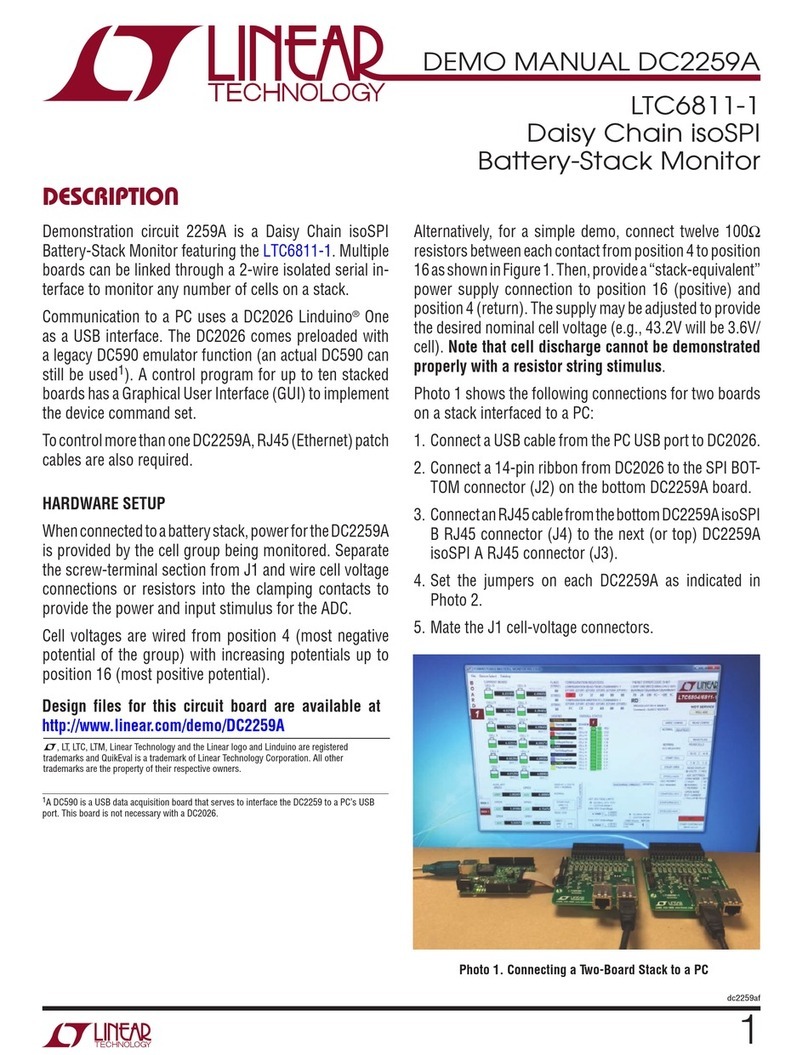

Photo 1. Connecting a Board to a PC

Design files for this circuit board are available at

http://www.linear.com/demo/DC2260A

Alternatively, for a simple demo, connect twelve 100Ω

resistors between each contact from position 4to position

16as shown in Figure 1. Then, provide a “stack-equivalent”

power supply connection to position 16 (positive) and

position 4 (return). The supply may be adjusted to provide

the desired nominal cell voltage (e.g., 43.2V will be 3.6V/

cell). Note that cell discharge cannot be demonstrated

properly with a resistor string stimulus.

Photo 1 shows the following connections for one board

interfaced to a PC:

1. Set jumpers on the board per Figure 1.

2. Connect a USB cable from the PC USB port to DC2026.

3. Connect a 14-pin ribbon from DC2026 to the SPI con-

nector (J2) on DC2260A.

4. Mate the J1 cell-voltage connector. The blue LED will

illuminate when powerisapplied. The brightnessreflects

the supply current.

1A DC590 is a USB data acquisition board that serves to interface the DC2259 to a PC’s USB

port. This board is not necessary with a DC2026.

2

dc2260af

DEMO MANUAL DC2260A

Photo 2. Connections and Jumpers

DESCRIPTION

3

dc2260af

DEMO MANUAL DC2260A

Figure 1. Simple Cell Simulator Using Resistors

DESCRIPTION

4

dc2260af

DEMO MANUAL DC2260A

ISOLATING THE HOST AND ADDING BOARDS

The LTC6811-2 can be operated using the isoSPI ports

(J3 and J4) rather than the conventional SPI port (J2), if

desired. To operate more than one DC2260A, it is actually

necessary to use the isoSPI feature to create the com-

munication bus. To operate with isoSPI, the following is

necessary:

n ADC1941isoSPI adapter board (to provide the LTC6820

interface IC) that provides the conversion from the

14-contact ribbon cable connection to an RJ45 isoSPI

port. With large numbers of isoSPI devices on a bus,

the DC1941 may require slight hardware modifications

to optimize the bus performance.

n Reconfiguration of all DC2260A ISOMD jumpers to the

“1” position (JP1, 2, 3, 5, 6).

n Interconnection of isoSPI ports with RJ45 patch cables

(J3 and J4 are interchangeable).

n TERMination jumpers (JP11) on DC2260A should all be

set to “0” except for the unit electrically furthest from

the DC1941 (JP11 set to “1”).

SOFTWARE SETUP

To use the DC2026 USB interface board, download the

free driver for a program called QuikEval™from http://

www.linear.com/designtools/software.

The separate GUI program is provided in a zipped file

(LTC6804_6811_GUI_Vxx.zip):

1. Unzip this folder

2. Run the setup.exe file to start installation

3. Ignore the Security Warning by selecting Install

The GUI control panel appears immediately after installa-

tion. Subsequent starts of the GUI are done through the

Windows Start menu or the optional Windows Desktop

shortcut icon.

DESCRIPTION

Figure 2. GUI Control Panel Start-Up Screen

5

dc2260af

DEMO MANUAL DC2260A

GUI STARTUP

Figure 2 is the initial start-up screen that appears when

the program is launched. Once power is supplied to the

board from a stack of cells or a power supply, the com-

munication between the PC and the board can be checked.

1. Set Device Mode

Click the command button labeled READ CONFIG. If all

is properly connected and operating, the start-up default

configuration of the LTC6811-2 will be read from the

board. The Hex codes for the six bytes of configuration

setting will appear in the CONFIGURATION REGISTERS

section in the boxes labeled CONFIGURATION READ FROM

LTC6804/6811-2. The initial configuration bytes should be

0xD8 for register 0 and 0x00 for the other five bytes. This

default configuration is the sleep mode for the LTC6811-2

on DC2260A.

The LTC6811 calculates a 15-bit Packet Error Code,

PEC15, as a 16-bit word and appends it to the data stream

each time it sends out data. For the six bytes sent by this

command and received by the GUI, the control program

calculates a PEC15 in the same manner. This 16-bit word

is compared with the appended received 16-bit word to

check that the data transmission was properly executed.

The received PEC15 word and the calculated PEC15 word

from the received data are displayed in the top section

labeled PACKET ERROR CODE 15-BIT and both words

should match. The oval located at the top of the color-

coded status panel for the one board will turn green if

the PEC15 words match. Data transmission errors will

produce red warning indications when the PEC15 words

do not match. There is also a display of the PEC15 that

was sent with the most recent command to the LTC6811.

3. Write Configuration

Nothing is changed within the LTC6811 until the Write

Configuration command is executed. Clicking the WRITE

CONFIG command buttonsends the command andthen the

six Hex bytes shown in the CONFIGURATION REGISTERS

section in the boxes labeled CONFIGURATION WRITTEN

TO LTC6804/6811-2 will become bold type. Software

developers can note the exact hex values required by the

LTC6811 for specific conditions in these boxes to facilitate

their control program development.

OPERATING THE CONTROL SCREEN

Click the Device Select menu, upper left of the GUI, then

click LTC6804/6811-2 Addressable to set the correct GUI

mode. Additional controls will appear and the upper right

GUI label will display LTC6804/6811-2.

2. Read Configuration

6

dc2260af

DEMO MANUAL DC2260A

In the section labeled SET VOLTAGE LIMITS, click on the

boxes and enter voltage values for the overvoltage and

undervoltage thresholds appropriate for the cells being

monitored. The voltage value entered will be rounded to

the actual value used by the LTC6811 and displayed in

the box. The voltage ranges for these thresholds is 0Vto

6.5520V.

These monitor thresholds can be applied globally to each

and every cell in the system or customized for the cells

connected to an individual board by clicking the desired

option button. Individual boards are selected for program-

ming by the left hand tabs in multiple board systems. Click

the WRITE CONFIG button to send the data and then a

READ CONFIG to verify it.

5: Read Cell Voltages

OPERATING THE CONTROL SCREEN

Clicking the READ CONFIG button can give confirmation

that the configuration change was actually made. Five of

the six bytes read back should match the bytes sent and

the PEC15/CRC15 check 16-bit words should be a match

(green PEC oval on stack display).

When any configuration information is changed on the

screen, the WRITE CONFIG command button will be il-

luminated, serving as a reminder that this command still

needs to be executed.

Set REFUP to 1 followed by a WRITE CONFIG command.

The Watchdog Timer (WDT) will now be prevented from

expiring by issuing a repeating POLL ADC command, and

the stack is ready to be monitored.

NOTE: No configuration changes take effect until the

WRITE CONFIG button is clicked. Leaving REFUP at the

default setting of 0, the WDT times out in 2 seconds

and all configuration information is reset.

4. Program the Cell Monitoring Voltage Thresholds

The essential function of the LTC6811 is to measure and

report the voltage on each battery cell when commanded.

First click on the STARTCELL button. This commands an

A/D conversion of all 12-cell voltages in the bit-resolution

configured from the selected CONV MODE (Conversion

Mode) in the ADC SETTINGS box. The actual cell voltage

7

dc2260af

DEMO MANUAL DC2260A

measurements are displayed in groups of 3 when each

command button inside the READ CELLS box is clicked.

NOTE:The READ DISPLAY box has options to display

Cell Voltages in VOLTS or HEX. First select VOLTS or

HEX then click on one of the command buttons inside

READ CELLS box. Every time a command button

inside the READ CELLS box is clicked;new data is

downloaded from the board and displayed as selected

in VOLTS or HEX.

6: Discharge Cells

OPERATING THE CONTROL SCREEN

The LTC6811 offers the option of keeping the discharge

transistors on while measuring the cell voltages. This is

done using the STARTCELL DCC command button. The

command button is illuminated blue when this command

has been executed.This lower voltage readingalso includes

I•R errors introduced by cabling and connectors.

7. Other Control Features

Additional command buttons are provided on the control

screen. The POLL ADC command button is used to test

if the ADC is busy making conversions of any LTC6811

devices in a system. The result of this command can be

observed by monitoring the serial data output line of the

SPI interface to the Bottom Port, J2. There is no indication

provided on the control screen.

The START OPEN (WIRE) command button connects

the built in open wire detection circuitry to all cells. This

command must be followed by any command buttons

inside the READ CELLS box click to see the result. The

OPEN WIRE TEST CURRENT box provides options to use

either PULLUP or PULLDOWN Open Wire Test Currents.

An open wire connection to any cell will be indicated by an

abnormally high voltage measurement for the cell above

the open wire and a near zero measurement for the cell

with the open wire in the PULLDOWN case.

8. Continuous Operation

The LTC6811 includes the ability to remove charge from

individual cells to help equalize cell charges within a stack

of batteries. DC2260A contains a P-channel MOSFET in

series with a 33Ω resistor across each cell connection.

When enabled, a cell is loaded and charge is pulled from

the cell with energy dissipated in the switch and resistor.

A check box is provided for each cell to be discharged.

Checking this box (Cell 2 in the above example screen

shot) and then writing the new configuration with a WRITE

CONFIG button push will load the cell.

The discharge transistors are automatically turned off

momentarily while the A/D converter is measuring the

cell voltage using the normal STARTCELL command. This

prevents any voltage drop errors caused by the discharge

current flowing through the cellinter-connection wiring. An

accurate indication of the true cell voltage is then obtained.

8

dc2260af

DEMO MANUAL DC2260A

OPERATING THE CONTROL SCREEN

For convenience, the control panel allows for continuous

operation of the DC2260A board. When the command

button labeled START CONTINUOUS READ CELLS is se-

lected, the GUI operates in a continuous loop executing

the following command sequence automatically:

n Start cell voltage

n Read cell voltage groups A (1 –3) , B (4 –6), C (7 –9),

and D (10 – 12)

n Read flags

Options available are the READ DISPLAY box, ADC SET-

TINGS box, OPEN WIRE TEST CURRENT box, and the

CONTINUOUS box. The CONTINUOUS box allows the

selection of STARTCELL, STARTOPEN, STARTCELL DCC,

and STARTOPEN DCC commands to be executed during

continuous operation. The options are useful for monitor-

ing the cell voltage measurements under different ADC

Test Conditions.

All values are updated continually (update rate is~500ms).

While running, the configuration can be changed on the

fly. Simply changing a configuration item (Discharge cells

for example) and clicking the WRITE CONFIG button will

implement the new configuration and return to continu-

ous operation.

A green box with the label ON in the lower right corner

of the GUI indicates that the system is running continu-

ously. A red box with the label OFF means that the system

is stopped and waiting for a new command to be sent.

DATALOGGING OPERATION

The GUI program can “datalog” or store cell voltage re-

sults in a CSV (Comma Separated Value *.csv) file. This

feature is useful in characterizing cell voltages over time.

Datalogging operates similarly to continuous operationbut

has the added functionality of storing results in a CSV file.

1. At the upper left of the GUI, click on the Datalog Menu

then Enable Datalog.

Datalog Mode is enabled when a maroon box appears to

the left of the START CONTINUOUS READ CELLS com-

mand button and the red box label changes from OFF to

DATALOG OFF. Datalog Mode is disabled when the maroon

box disappears and the red box label reverts to OFF.

NOTE: The *.csv filenames include the time created and

are stored by default into the “C:\Datalog6804_6811\”

folder. More details are in the file “AboutCurrentVersion.

txt” inside the GUI’s installation folder (normally “C:\

ProgramFiles\LT C \MultiCellBatteryMonitor\LTC6804”).

2. Click on the START CONTINUOUS READ CELLS com-

mand button to start datalogging onto a new CSV file.

Elapsed Time =Total time of Datalog from start to finish.

Total Data Points =Total data points of Datalog from

start to finish. Refresh =Time in seconds (S) between

each Read Cells command;also known as Sample or

Update Rate.

3. Click onthe STOPCONTINUOUS READ CELLScommand

button to stop datalogging and close the CSV file.

9

dc2260af

DEMO MANUAL DC2260A

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representa-

tion that the interconnection of its circuits as described herein will not infringe on existing patent rights.

4. The CSV file is ready to view. Go to “C:\Data-

Log6804_6811\” folder and open file.

2. A tab will appear on the left edge of the control panel

for each board on the stack. Clicking on any of these

tabs will transfer control commands and data to and

from the display screen to that selected board.

3. Select whether the ADC’s Voltage Reference Powered

State (Ref Up) and Over-/Undervoltage thresholds for

each board are to be the same (GLOBAL) or different for

each board (CUSTOM) and set the Ref Up and voltages

accordingly.

COLOR CODED STATUS PANEL

The color-coded status panel will expand to include all

boards connected in a stack. Each small square in this

array represents an individual battery in the stack of

boards. The intent of this display is to provide a way to

see the status of all cells at a glance. The significance of

the colors used is explained in the legend on the screen.

Consult the data sheet for detailed information concerning

the operation of the LTC6811-2.

COMMANDS SUPPORTED (V05 VERSION):

POLLADC

WRITECONFIG (REFUP,VUV,VOV,Discharge selected cells)

READ CONFIG

STARTCELL and OPEN WIREconversions with and without

discharge connected (ADC Settings:Conversion Mode,

Open Wire Test Current)

READ CELL GROUPS (A, B, C and D. Read Volts/Hex)

START CONTINUOUS reads all cells every ~500ms.

COMMANDS NOT SUPPORTED (V05 VERSION):

SELFTEST

GPIO Logic Functions

READ FLAGS

READ AUX

OPERATING THE CONTROL SCREEN

5. View the CSV file in a compatible spreadsheet software

program such as MS Excel.

SOFTWARE ADJUSTMENTS

The GUI program can control up to ten boards on a stack.

1. Select thenumber ofboards onthestackby slidingthe track

bar up or down;located at the bottom left of the screen.

10

dc2260af

DEMO MANUAL DC2260A

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ●FAX: (408) 434-0507 ●www.linear.com

© LINEAR TECHNOLOGY CORPORATION 2015

LT 1215 • PRINTED IN USA

DEMONSTRATION BOARD IMPORTANT NOTICE

Linear Technology Corporation (LTC) provides the enclosed product(s) under the following AS IS conditions:

This demonstration board (DEMO BOARD) kit being sold or provided by Linear Technology is intended for use for ENGINEERING DEVELOPMENT

OR EVALUATION PURPOSES ONLY and is not provided by LTC for commercial use. As such, the DEMO BOARD herein may not be complete

in terms of required design-, marketing-, and/or manufacturing-related protective considerations, including but not limited to product safety

measures typically found in finished commercial goods. As a prototype, this product does not fall within the scope of the European Union

directive on electromagnetic compatibility and therefore may or may not meet the technical requirements of the directive, or other regulations.

If this evaluation kit does not meet the specifications recited in the DEMO BOARD manual the kit may be returned within 30 days from the date

of delivery for a full refund. THE FOREGOING WARRANTY IS THE EXCLUSIVE WARRANTY MADE BY THE SELLER TO BUYER AND IS IN LIEU

OF ALL OTHER WARRANTIES, EXPRESSED, IMPLIED, OR STATUTORY, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS

FOR ANY PARTICULAR PURPOSE. EXCEPT TO THE EXTENT OF THIS INDEMNITY, NEITHER PARTY SHALL BE LIABLE TO THE OTHER FOR

ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES.

The user assumes all responsibility and liability for proper and safe handling of the goods. Further, the user releases LTC from all claims

arising from the handling or use of the goods. Due to the open construction of the product, it is the user’s responsibility to take any and all

appropriate precautions with regard to electrostatic discharge. Also be aware that the products herein may not be regulatory compliant or

agency certified (FCC, UL, CE, etc.).

No License is granted under any patent right or other intellectual property whatsoever. LTC assumes no liability for applications assistance,

customer product design, software performance, or infringement of patents or any other intellectual property rights of any kind.

LTC currently services a variety of customers for products around the world, and therefore this transaction is not exclusive.

Please read the DEMO BOARD manual prior to handling the product. Persons handling this product must have electronics training and

observe good laboratory practice standards. Common sense is encouraged.

This notice contains important safety information about temperatures and voltages. For further safety concerns, please contact a LTC application

engineer.

Mailing Address:

Linear Technology

1630 McCarthy Blvd.

Milpitas, CA 95035

Copyright © 2004, Linear Technology Corporation

This manual suits for next models

1

Table of contents

Other Linear Technology Monitor manuals