QUICK START GUIDE FOR DEMONSTRATION CIRCUIT 776

36V-72VIN, FORWARD CONVERTER

2

PWM gate pulses to the LTC3705 primary driver via

the small signal transformer, T3. The LTC3705 then

operates as a simple driver receiving both input sig-

nals and bias power through T3.

The transition from primary to secondary control oc-

curs seamlessly at a fraction of the output voltage.

From that point on, operation and design simplifies to

that of a simple buck converter. Secondary sensing

eliminates delays, tames large-signal overshoot and

reduces output capacitance. This, while utilizing off-

the-shelf magnetics and attaining high efficiency.

For large values of input inductance, a 100V, 47uF elec-

trolytic capacitor can be added across the input termi-

nals to damp the input filter and provide adequate stabil-

ity. See Linear Technology Application Note AN19 for a

discussion on input filter stability analysis. A recom-

mended part is the Sanyo 100MV39AX.

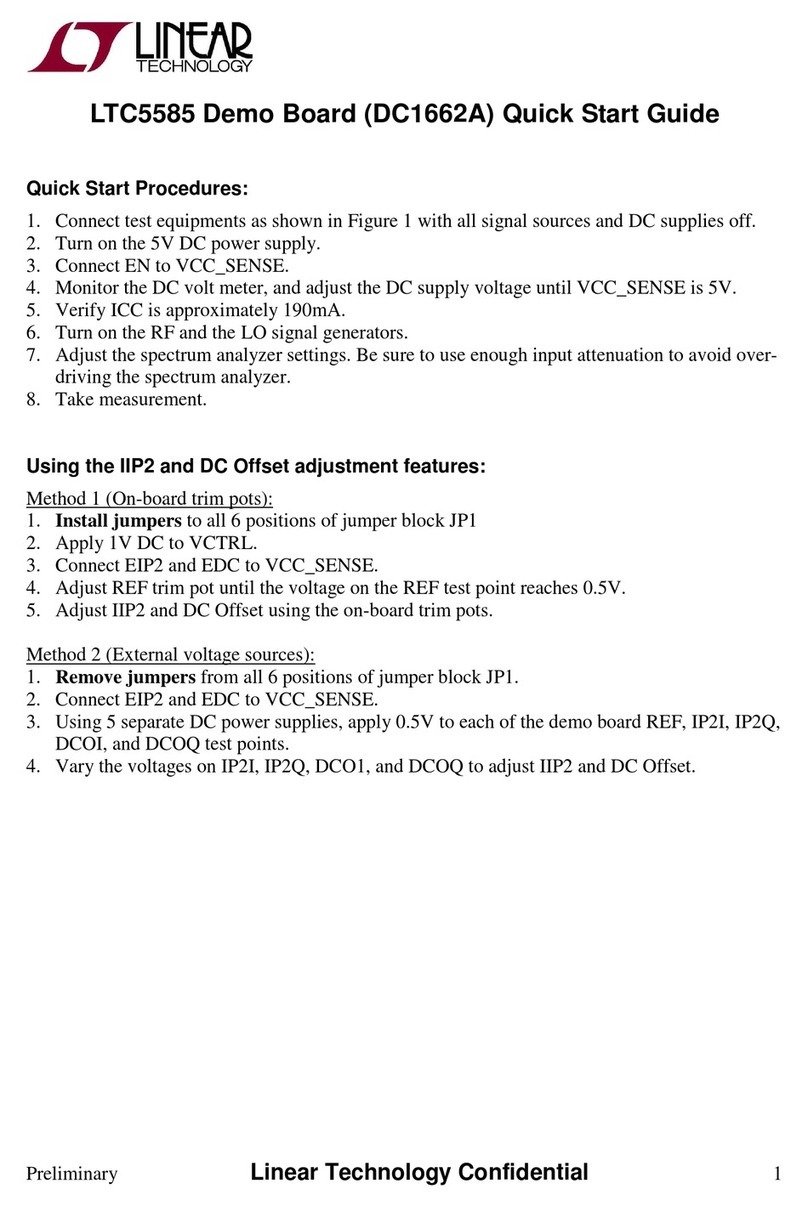

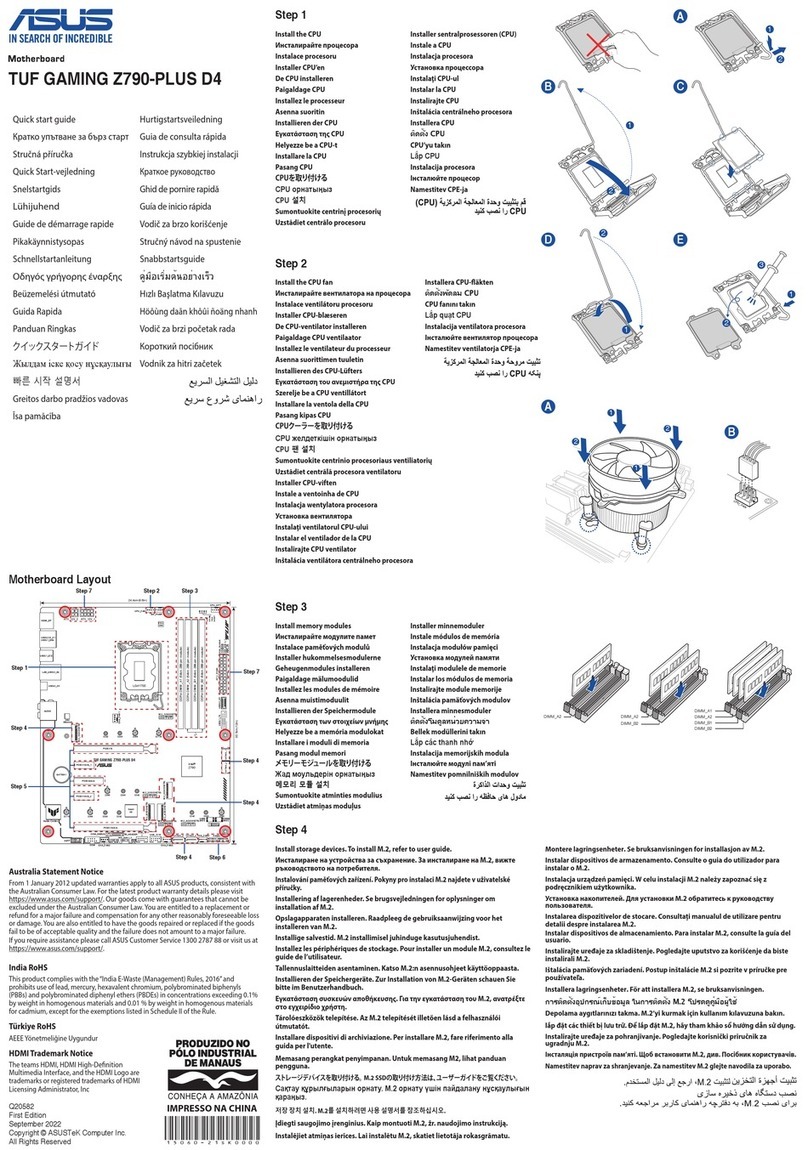

QUICK START PROCEDURE

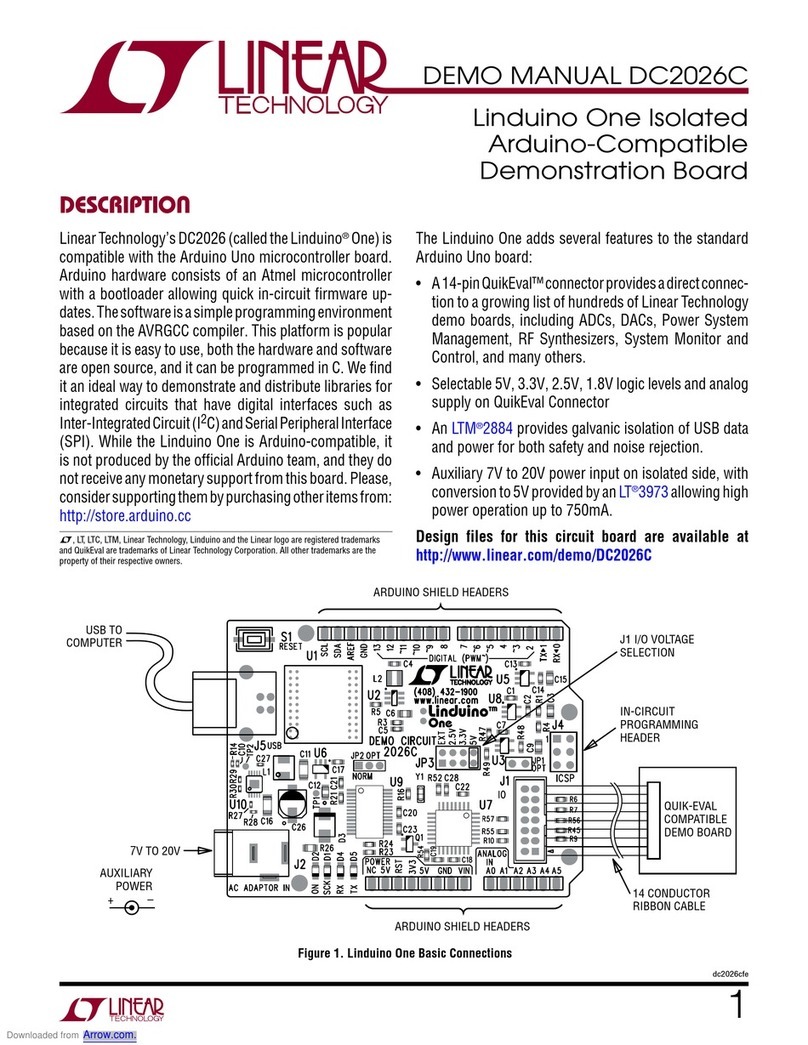

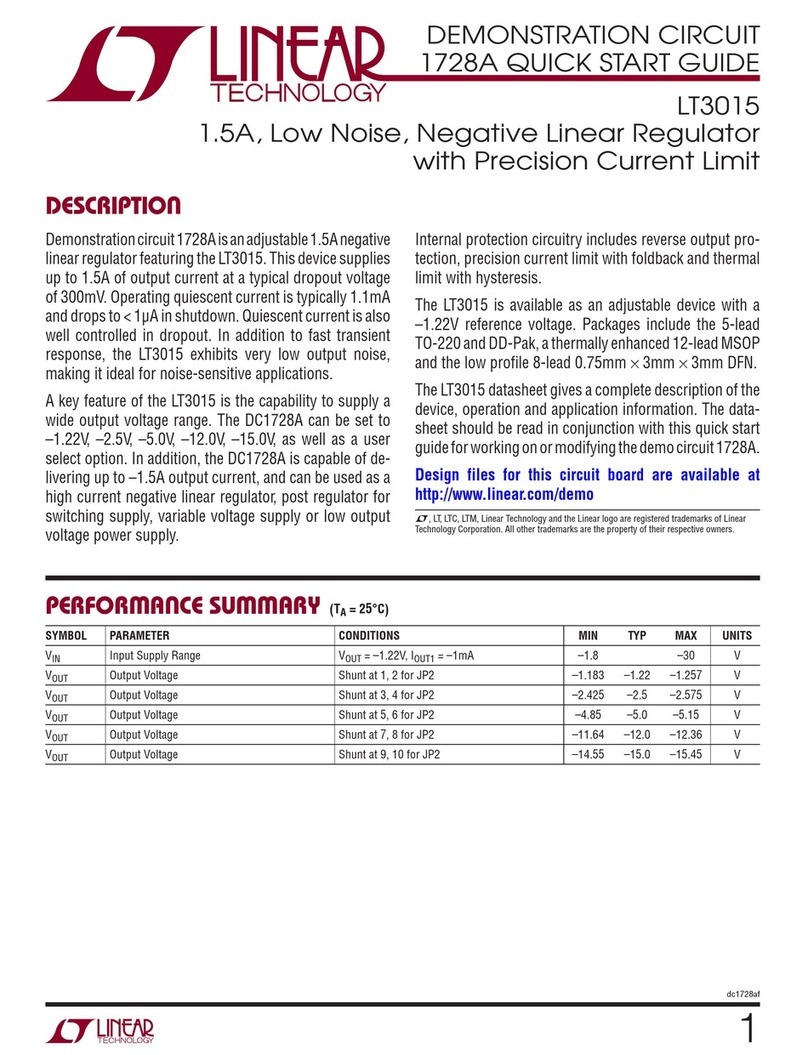

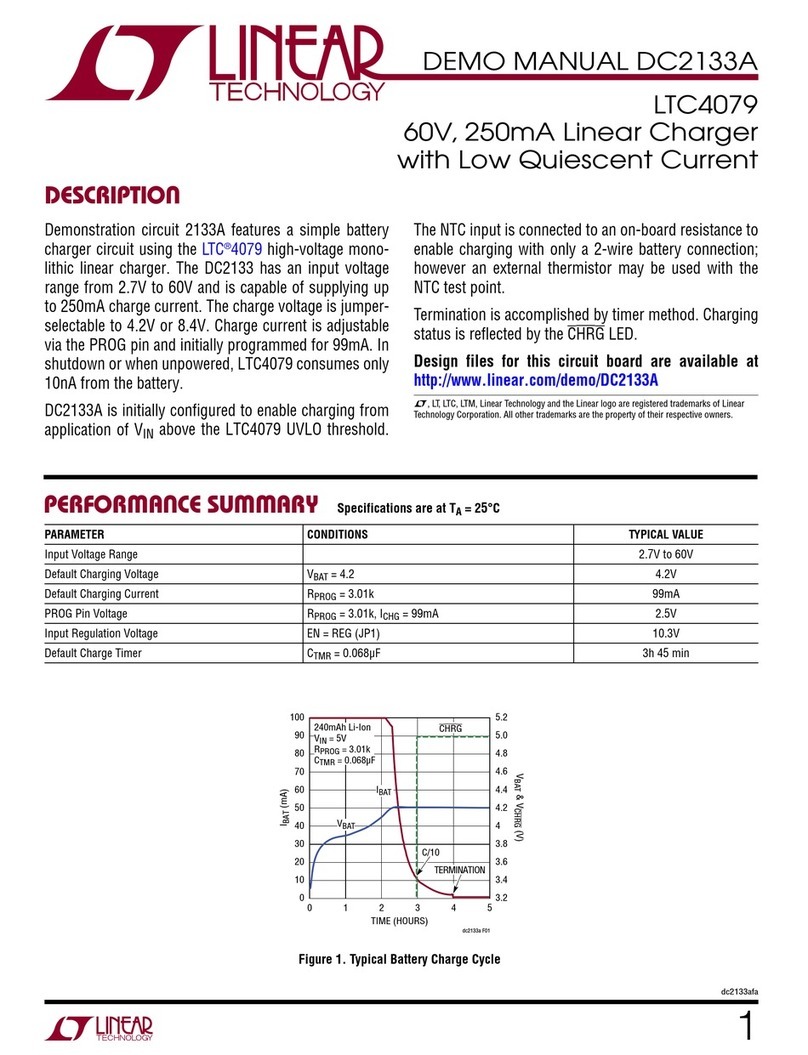

Demonstration circuit 776 is easy to set up to evalu-

ate the performance of the LTC3705 and LTC3706.

Refer to Figure 1 for proper measurement equipment

setup and follow the procedure below:

NOTE:

When measuring the input or output voltage

ripple, care must be taken to avoid a long ground lead

on the oscilloscope probe. Measure the output (or

input) voltage ripple by touching the probe tip and

probe ground directly across the +Vout and –Vout (or

+Vin and –Vin) terminals. See Figure 2 for proper

scope probe technique.

1.

Set an input power supply that is capable of 36V to

72V to a voltage of 36V. Then turn off the supply.

2.

With power off, connect the supply to the input

terminals +Vin and –Vin.

a.

Input voltages lower than 36V can keep the con-

verter from turning on due to the undervoltage

lockout feature of the LTC3705.

b.

If efficiency measurements are desired, an am-

meter capable of measuring 3Adc can be put in

series with the input supply in order to measure

the DC776A’s input current.

c.

A voltmeter with a capability of measuring at

least 72V can be placed across the input termi-

nals in order to get an accurate input voltage

measurement.

3.

Turn on the power at the input.

NOTE:

Make sure that the input voltage never ex-

ceeds 72V.

4.

Check for the proper output voltage of 1.5V ± 1%.

Turn off the power at the input.

5.

Once the proper output voltages are established,

connect a variable load capable of sinking 50A at

1.5V to the output terminals +Vout and –Vout. Set

the current for 0A.

a.

If efficiency measurements are desired, an am-

meter or a resistor shunt that is capable of han-

dling 50Adc can be put in series with the output

load in order to measure the DC776A’s output

current.

b.

A voltmeter with a capability of measuring at

least 2V can be placed across the output termi-

nals in order to get an accurate output voltage

measurement.

6.

Turn on the power at the input.

NOTE:

If there is no output, temporarily disconnect

the load to make sure that the load is not set too

high.

7.

Once the proper output voltage is again estab-

lished, adjust the load within the operating range

and observe the output voltage regulation, ripple

voltage, efficiency and other desired parameters.