8 9

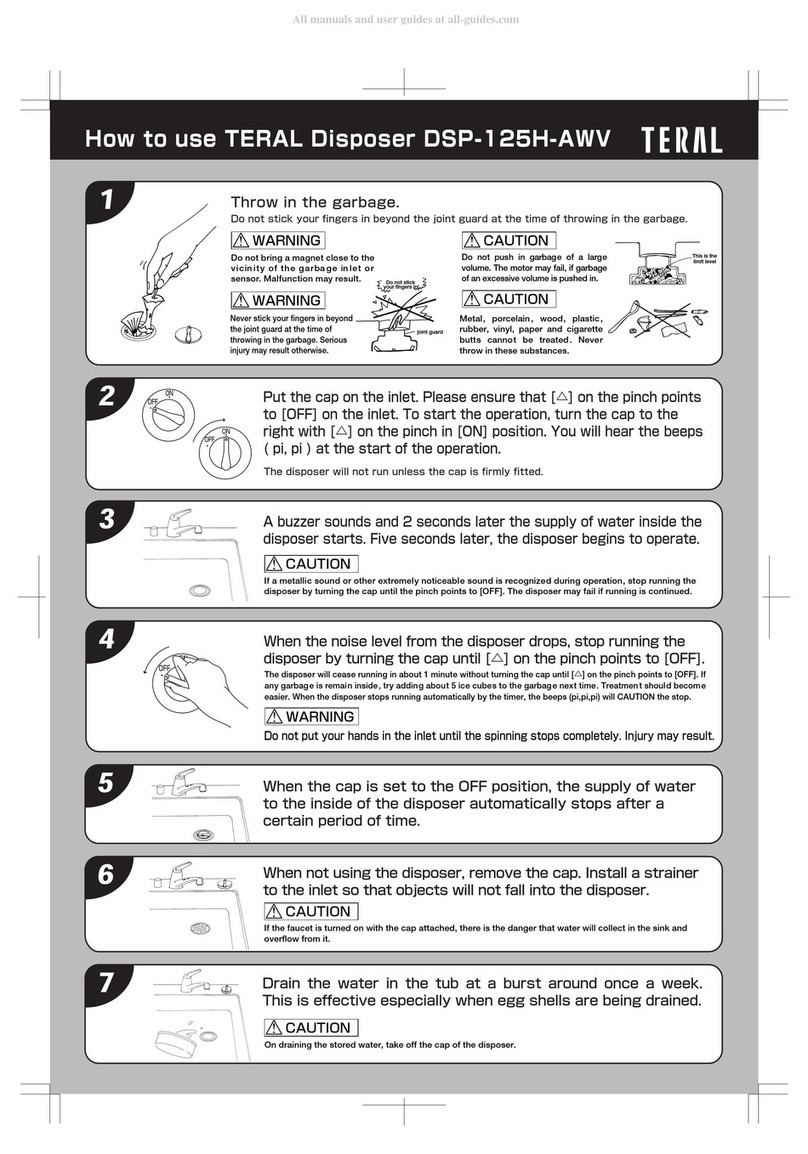

Installing your unit – ABS Clip Model

NOTE: Pay close attention to the assembly sequence of mount assembly

components, as they have been correctly assembled during production.

Remove the fastening ring by releasing1.

the lock catch.

Remove mount assembly from disposer.2.

Unscrew support ring from sink flange and3.

remove protector gasket and fibre gasket.

You are now left with sink flange and

rubber gasket.

The rubber gasket is used instead of4.

plumbers putty with stainless steel sinks.

Other sinks (ceramic, stone etc) will require

putty.

If no putty is required, insert sink flange5.

through rubber gasket into sink opening.

Do not rotate sink flange once it is seated.

If using putty instead of the gasket, form6.

a ring around the sink flange. Insert flange

into sink opening, press down hard to

squeeze out excess putty. From under

sink, trim o excess putty flush with

bottom edge of sink opening.

From underneath sink, slip fibre gasket7.

onto exposed sink flange. With arrows

pointing up, screw support ring onto the

sink flange, hand tighten until the sink

flange will not move. At this point you may

want to insert stopper in sink and fill with

water to check sink flange seal and insure

there are no leaks.

Lift the machine up with two hands and let the sink flange insert into the8.

splash guard and make sure that the groove on the inside of the splash guard

fits over lip on sink flange. At the same time, make sure that the discharge

outlet faces towards the location of the drain pipe.

Put the fastening ring around the splash guard and lock the buckle, checking9.

that the installation is firm and stable. If everything is OK, go on to install the

elbow and make the connection to the waste pipe.

1

2

3

4 5