Troxler 5850v2 Guide

Manual of Operation and Instruction

Model 5850v2

Gyratory Compactor

NOTE

Before using the Model 5850v2 Gyratory Compactor,

carefully read this manual. It is especially important to

understand the Safety Warnings on page 1–1. Keep this

manual in a safe place that is always easily accessible

during the use of the Model 5850v2.

Troxler Electronic Laboratories, Inc.

3008 E. Cornwallis Road P.O. Box 12057

Research Triangle Park, NC 27709 U.S.A.

Phone: 1.877.TROXLER

Outside the U.S.A.: +1.919.549.8661

Fax: +1.919.549.0761

www.troxlerlabs.com

ii

Troxler products are protected by U.S. and foreign patents.

Copyright 2009 –2015

Troxler Electronic Laboratories, Inc.

All Rights Reserved

No part of this manual may be reproduced or transmitted in any

form or by any means, electronic or mechanical, including

photocopying, recording, or information storage and retrieval

systems, for any purpose without the express written permission of

Troxler Electronic Laboratories, Inc.

Bindoff is a registered trademark of Chemical Solutions, Inc.

Magnalube-G is a registered trademark of Magnalube, Inc.

Superpave is a trademark of the Strategic Highway Research

Program.

PN 116901

October 2015

Edition 3.0

Model 5850v2 iii

TROXLER SERVICE CENTERS

Troxler Corporate Headquarters

3008 E. Cornwallis Road • P.O. Box 12057

Research Triangle Park, NC 27709

Phone: 1.877.TROXLER (1.877.876.9537)

Outside the U.S.A.: +1.919.549.8661

Fax: +1.919.549.0761

Web: www.troxlerlabs.com

Technical Support

Phone: 1.877.TROXLER (1.877.876.9537)

E-mail: TroxTechSupport@troxlerlabs.com

NORTH CAROLINA SERVICE

CENTER

3008 E. Cornwallis Road

Research Triangle Park, NC 27709

Phone: +1.919.549.8661

Fax: +1.919.549.0761

TroxT[email protected]m

FLORIDA BRANCH OFFICE &

SERVICE CENTER

2376 Forsyth Road

Orlando, FL 32807

Phone: +1.407.681.4221

Fax: +1.407.681.3188

TroxT[email protected]m

MIDWESTERN BRANCH

OFFICE & SERVICE CENTER

1430 Brook Drive

Downers Grove, IL 60515

Phone: +1.630.261.9304

Fax: +1.630.261.9341

TroxT[email protected]m

WESTERN BRANCH OFFICE &

SERVICE CENTER

11300 Sanders Drive, Suite 7

Rancho Cordova, CA 95742

Phone: +1.916.631.0234

Fax: +1.916.631.0541

TroxT[email protected]m

SOUTHWESTERN BRANCH

OFFICE & SERVICE CENTER

2016 East Randol Mill Road

Suite 406

Arlington, TX 76011

Phone: +1.817.275.0571

Fax: +1.817.275.8562

TroxT[email protected]m

TROXLER EUROPE &

SERVICE CENTER

Troxler Electronics GmbH

Gilchinger Strasse 33

D.82239 Alling nr.

Munich, Germany

Phone: ++ 49.8141.71063

Fax: ++49.8141.80731

TROXLER ELECTRONIC TECHNOLOGIES (ZHANGJIAGANG)

1F, Building G, No. 1 Guotai North Road

ZJG, China, 215600

Phone: 0086.512.56793702 Fax: 0086.512.56793701

NOTE

To locate an independent, Troxler-authorized service

partner near you, call 1.877.TROXLER (1.877.876.9537).

iv

ABOUT THIS MANUAL

The Model 5850v2 Manual of Operation and Instruction provides

detailed information about the compactor. The manual includes

product safety information, as well as instructions for the proper

installation and use of the compactor.

This manual is organized as follows:

Chapter 1, Introduction to the Model 5850v2 –Provides

information on the safe use of the compactor; a brief overview

of the compactor and its features; a list of parts and accessories;

and instructions for unpacking and inspection.

Chapter 2, Setup and Operation –Describes the compactor

keypad, and provides instructions for setting up, starting, and

operating the compactor.

Chapter 3, Setup Menu –Provides a detailed description of the

options available from the compactor’s Setup menu.

Chapter 4, Calibration and Verification –Includes instructions

for calibrating the compactor and verifying its calibration.

Chapter 5, Special Functions –Describes the functions available

from the compactor’s Special menu.

Appendix A, Troubleshooting and Service –Provides

maintenance and service information, as well as instructions on

basic troubleshooting.

Appendix B, Menu Map –Shows a map of the compactor’s Setup

menu.

Appendix C, Specifications –Contains the environmental,

performance, electrical, and mechanical specifications of the

compactor.

Model 5850v2 v

HOW TO USE THIS MANUAL

Congratulations on the purchase of the Model 5850v2 Gyratory

Compactor.

The Model 5850v2 Manual of Operation and Instruction contains

information on safely using this unit. Also included in this manual

are safety warnings, basic parameter setup, system troubleshooting,

and general maintenance.

Do not attempt to operate the Model 5850v2 before reading this

manual and the safety warnings posted on the unit. Troxler stresses

that the user is solely responsible for ensuring the safe use of the

Model 5850v2. The manufacturer, its subsidiary, representatives,

and distributors cannot assume responsibility for any mishaps,

damage, or personal injury that may occur from failure to observe

the safety warnings in this manual and posted on the unit.

vi

CONVENTIONS USED IN THIS MANUAL

Throughout this manual, symbols and special formatting are used to

reveal the purpose of the text as follows:

WARNING

Warnings indicate conditions or procedures that, if

not followed correctly, may cause personal injury.

CAUTION

Cautions indicate conditions or procedures that, if not

followed correctly, may cause equipment damage.

NOTE

Notes indicate important information that must be read

to ensure proper operation.

KEYAngle brackets and a different typestyle indicate a

key or character (number or letter) to press on the

compactor keypad. For example, “Press START”

means to press the key labeled START.

DISPLAY A different typestyle is used in text to indicate

information or messages displayed on the

compactor.

DISPLAY- Typestyle and

shading used to

simulate the control

panel display

1

1.

.

Numbers indicate a procedure with multiple steps.

Diamonds indicate a list of things needed (such as

equipment) or things to know.

Triangles indicate that more than one option is

available. Carefully select the option that applies.

Model 5850v2 vii

TABLE OF CONTENTS

About This Manual.......................................................................... iv

CHAPTER 1................................................................................ 1–1

Safety Warnings............................................................................ 1–1

Cautions and Warnings................................................................. 1–3

Introduction................................................................................... 1–4

Parts and Accessories.................................................................... 1–8

Inspection...................................................................................... 1–9

Unpacking................................................................................... 1–10

Site Selection.............................................................................. 1–11

Assembly .................................................................................... 1–12

CHAPTER 2................................................................................ 2–1

Control Panel................................................................................ 2–2

Turning the System On................................................................. 2–4

Compacting a Specimen ............................................................... 2–6

Cleaning and Lubricating.............................................................. 2–8

Preparing a Specimen ................................................................. 2–10

Compacting the Specimen.......................................................... 2–14

Removing the Sample from the Mold......................................... 2–15

Cooling the Sample..................................................................... 2–16

Shear Options & Performance Tests........................................... 2–16

CHAPTER 3................................................................................ 3–1

Setup Menu................................................................................... 3–2

View Settings................................................................................ 3–3

Change Settings............................................................................ 3–4

Home Position ............................................................................ 3–14

Calibration .................................................................................. 3–14

Special......................................................................................... 3–14

CHAPTER 4................................................................................ 4–1

Calibration Schedule..................................................................... 4–2

Angle Verification........................................................................ 4–3

Calibration .................................................................................... 4–5

CHAPTER 5................................................................................ 5–1

Special Menu ................................................................................ 5–2

Clock/Calendar............................................................................. 5–3

Erase Records ............................................................................... 5–6

Reset Software.............................................................................. 5–7

viii

APPENDIX A .............................................................................A–1

Troubleshooting............................................................................A–2

General Maintenance Schedule....................................................A–4

Replacing the Batteries.................................................................A–7

Cleaning the Cooling Fan.............................................................A–8

Replacement Parts........................................................................A–8

Returning Parts for Service ..........................................................A–9

APPENDIX B..............................................................................B–1

Menu Map Description.................................................................B–2

APPENDIX C .............................................................................C–1

Environmental Conditions............................................................C–2

Electrical Specifications...............................................................C–3

Mechanical Specifications............................................................C–4

INDEX

WARRANTY

Model 5850v2 ix

LIST OF FIGURES

Figure Title Page

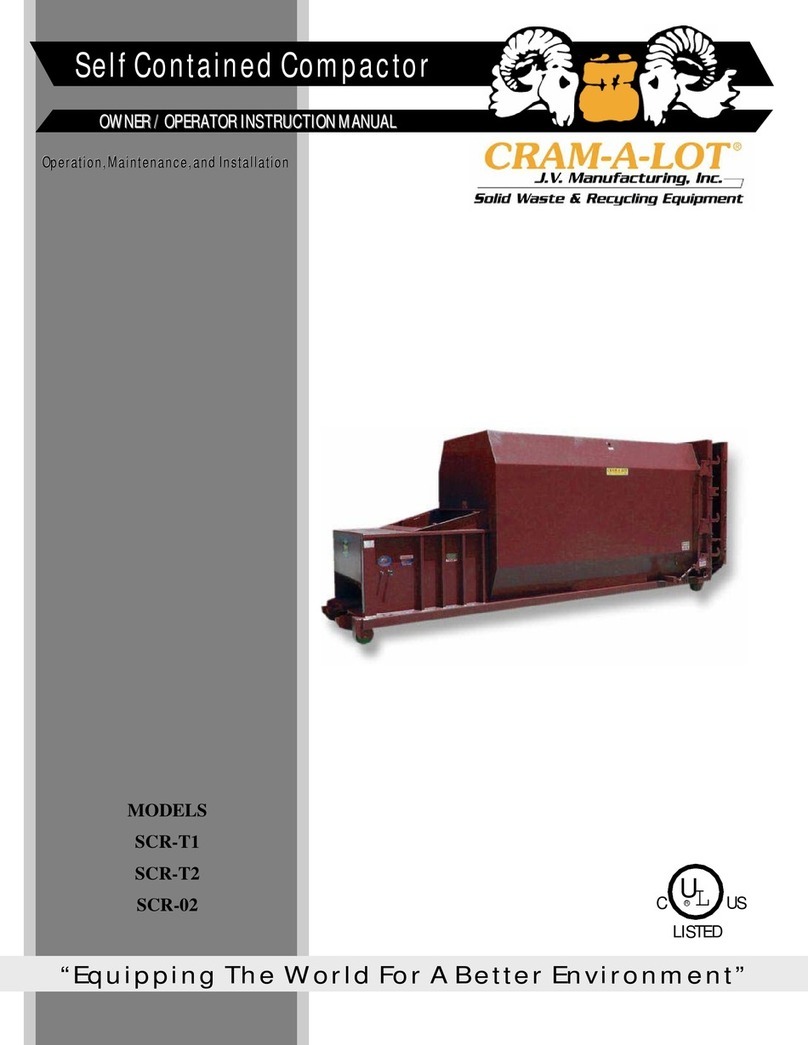

Figure 1–1. Model 5850v2 Gyratory Compactor .........................1–7

Figure 1–2. Hydraulic Reservoir ................................................ 1–12

Figure 1–3. Proper Reservoir Fill Level..................................... 1–13

Figure 1–4. Place a Funnel in Reservoir Fill Tube..................... 1–13

Figure 2–1. Model 5850v2 Control Panel Layout........................2–3

Figure 2–2. Compaction Chamber................................................2–9

Figure 2–3. Loading the Mold....................................................2–12

Figure 3–1. Sample Height Versus Gyration Table....................3–13

Figure 4–1. Aligning the Internal Angle Device Probes...............4–3

Figure 4–2. Puck Centered on Lower Carriage Plate ...................4–7

Figure 4–3. Routing Load Cell Cables .........................................4–8

Figure A–1. Hydraulic Filter Bypass Indicator............................ A–6

Figure B–1. Model 5850v2 Menu Map........................................B–3

x

LIST OF TABLES

Table Title Page

Table 2–1. Control Panel Keys and Button...................................2–2

Model 5850v2 1–1

1. INTRODUCTION

CHAPTER 1

INTRODUCTION TO THE MODEL 5850V2

The Model 5850v2 is Troxler’s newest Superpave™ Gyratory

Compactor and the most advanced, easiest to use gyratory

compactor on the market today. This chapter introduces the Model

5850v2 and provides information on operating the compactor safely.

This chapter also includes a list of parts and accessories, and

instructions for unpacking and inspecting the system.

SAFETY WARNINGS

The Troxler Model 5850v2 is a safe, durable gyratory compactor.

Troxler cannot anticipate every example of improper or

unauthorized use of this unit that may lead to malfunction or

accident. Thus, if a particular use is not specifically mentioned in

this manual as authorized, then consult Troxler about the alternate

use. Otherwise, it is assumed that the use is unauthorized and

improper.

To ensure minimal operator risk, Troxler recommends the following

safety precautions:

Wear safety glasses when preparing an asphalt specimen.

Always wear heat-resistant gloves when handling any hot

substance.

When moving the mold, grasp it firmly on either side under the

top flange.

Remove all objects, except the mold and asphalt specimen, from

the compaction chamber before pressing the STARTkey.

Do not operate the compactor with the chamber door or any

panels removed.

1–2

Do not wear loose clothing or jewelry when operating the

compactor.

Keep hands away from the gyratory compactor when the unit is

in motion.

With the service panels removed, the gyratory compactor poses

an electrical hazard. Unplug the gyratory compactor before

removing the panels.

Model 5850v2 1–3

1. INTRODUCTION

CAUTIONS AND WARNINGS

Identification of Interconnects:

Lower Left Side of Compactor

Connection for 100 –240 VAC, 50/60 Hz power to the

compactor

Upper Left Side of Compactor

9-pin RS-232C serial interface for connecting the

compactor to a computer or serial device

USB port for connecting the compactor to a USB

printer or memory device

1–4

INTRODUCTION

The Troxler Model 5850v2 SuperpaveGyratory Compactor

provides compaction of asphalt specimens at a given pressure,

angle, and number of gyrations. The Model 5850v2 meets or

exceeds all Federal Highway Administration (FHWA) Superpave

specifications.

The Model 5850v2 Gyratory Compactor provides safe, reliable

gyratory compaction of asphalt specimens using a compaction

pressure and gyration angle selected by the operator. The method of

specimen compaction is crucial to creating asphalt specimens that

behave similar to asphalt used in construction and in obtaining

meaningful test results.

Building upon the successes of Troxler’s Model 4140 and 4141

Gyratory Compactors, the Model 5850v2 has been completely

redesigned with improved electronics, a robust compaction system,

and software-adjustable angle of gyration. The durable Model

5850v2 will consistently stand up to the rigors of any asphalt lab.

SAFE OPERATION

For operator safety, all moving parts are covered and cannot be

physically accessed during compaction. An interlock switch

prevents the gyratory compactor from operating with the

compaction chamber door open. The red EMERGENCYsafety

switch located at the bottom of the control panel stops all moving

parts.

WARNING

Do not operate the Model 5850v2 Gyratory

Compactor with the chamber door or any panels

removed.

Model 5850v2 1–5

1. INTRODUCTION

EASE OF OPERATION

The Model 5850v2 is calibrated and ready to use upon arrival. The

unit will compact asphalt samples to a specific height or a specific

number of gyrations, as selected by the operator. The angle of

gyration is recorded with every gyration, assuring angle stability.

As selected by the operator, the Model 5850v2 provides a

compaction pressure of 200 to 1000 kPa and an angle of gyration

between 0.00 and 1.50 degrees. Angle and pressure adjustments can

be performed quickly and easily using the keypad.

For ease of operation, the Model 5850v2 provides a fully automatic

method of compaction. The Model 5850v2 compacts an asphalt

specimen at the touch of a single key.

NOTE

Do not attempt to operate the Model 5850v2 before

reading this manual and the safety warnings posted on

the unit. Troxler stresses that the operator is solely

responsible for ensuring the safe use of the Model

5850v2. The manufacturer, its subsidiaries, distributors,

or representatives cannot assume responsibility for any

mishaps, damage, or personal injury which may occur

from failure to observe the safety warnings in this

manual and posted on the unit.

The Model 5850v2 can be equipped with 150-mm, 100-mm, or 4-

inch diameter molds, and can compact specimens with heights of up

to 185 mm.

The Model 5850v2 features USB and serial ports for transferring

data to USB or serial devices. The operator may choose to

automatically send the compaction data to a computer, printer, or

USB device upon completion of a compaction cycle.

NOTE

A list of USB memory devices and printers that are

compatible with the Model 5850v2 Gyratory Compactor

is available on the 5850v2 product page of the Troxler

website (www.troxlerlabs.com).

1–6

The Model 5850v2 also provides storage for and allows manual

printing of the last 20 compacted specimens. All output is in SI units

as described in American Society of Testing and Materials (ASTM)

SI10, Standard for Use of the International System of Units (SI):

The Modern Metric System.

CARE AND MAINTENANCE

The Model 5850v2 requires little maintenance. To reduce the effects

of gyration on moving parts, the gyratory compactor requires

regular cleaning and lubrication. For a schedule of machine

maintenance, refer to Appendix A.

Model 5850v2 1–7

1. INTRODUCTION

Figure 1–1. Model 5850v2 Gyratory Compactor

1–8

PARTS AND ACCESSORIES

The Model 5850v2 includes the electrical and mechanical parts

required to continuously compact hot-mix asphalt. Use Figure 1–1

to locate and identify the following parts:

The power switch is located on the left side of the compactor.

The emergency stop switch stops all machine movement.

The keypad and display provide the interface.

The mold (not shown) with the lower puck inserted receives the

asphalt for making specimens. Troxler offers molds with inside

diameters of 150 mm, 100 mm, and 4 inches. (Part numbers

116066 and 116069)

The USB and serial ports enable the operator to print or

download data to a USB or serial device.

The USB cable (not shown) connects the compactor to the

printer or other USB device. (Part number 110697)

The serial cable (not shown) connects the compactor to a serial

device, such as a computer. (Part number 106514)

The extruder is used to remove a compacted specimen from the

mold.

The cooling table is used to the compacted specimen.

The height standard assembly (not shown) is used to calibrate

the specimen height. (Part number 106989)

The Model 5850v2 Manual of Operation and Instruction (not

shown) provides the operating instructions for the compactor.

The printer (not shown) allows the operator to print data. (Part

number 116220)

The specimen papers (not shown) prevent the asphalt specimen

from sticking to the puck and ram head. (Part number 106953)

The optional Pressure Verification Kit (not shown) allows the

operator to verify the pressure calibration. The pressure is

initially calibrated at the factory. (Part number 108706)

Model 5850v2 1–9

1. INTRODUCTION

INSPECTION

Upon receiving the Model 5850v2 Gyratory Compactor from the

factory, perform a complete inspection and inventory as described

below.

Check to see that the following are included:

Model 5850v2 Gyratory Compactor

Mold

Power cord

Height standard assembly

Specimen papers (500 per package)

Printer

USB cable

Serial cable

Manual of Operation and Instruction

Inspect each part for damage that may have occurred during

shipment. If any parts or accessories appear damaged, notify the

carrier and your Troxler representative immediately.

1–10

UNPACKING

WARNING

The Model 5850v2 Gyratory Compactor weighs

approximately 227 kg (500 lb). To prevent personal

injury or equipment damage, exercise care while

unpacking and lifting the unit.

NOTE

Troxler recommends that all packaging material be

saved. It may be reused to pack the compactor for

shipping.

1

1.

.

To remove the shipping carton from the top of the unit, cut each

side of the carton approximately 2 inches above the pallet. Lift

the carton up and off the unit.

2

2.

.

Remove the metal strap and bolts that secure the compactor

to the pallet.

3

3.

.

Remove the two brackets that secure the front casters in

place. The compactor is now free to roll on the pallet.

WARNING

To prevent personal injury or equipment damage,

do not tip the compactor while lifting it from the

pallet.

4

4.

.

Using a forklift, lift the compactor from the pallet.

CAUTION

When using a forklift, lift the compactor from the side to

prevent equipment damage.

Table of contents

Popular Garbage Disposal manuals by other brands

Emerson

Emerson InSinkErator WasteXpress WX-500-7-WX101 manual

Weber mt

Weber mt CR 7-II Hd Operating and maintenance manual

KitchenAid

KitchenAid KCDS100T0 parts list

GE

GE GFC530F - DirectWire 1/2 HP Continuous Feed... specification

KitchenAid

KitchenAid KCDS075T0 parts list

GE

GE Disposall GFC720V Dimensional information