- 10 -

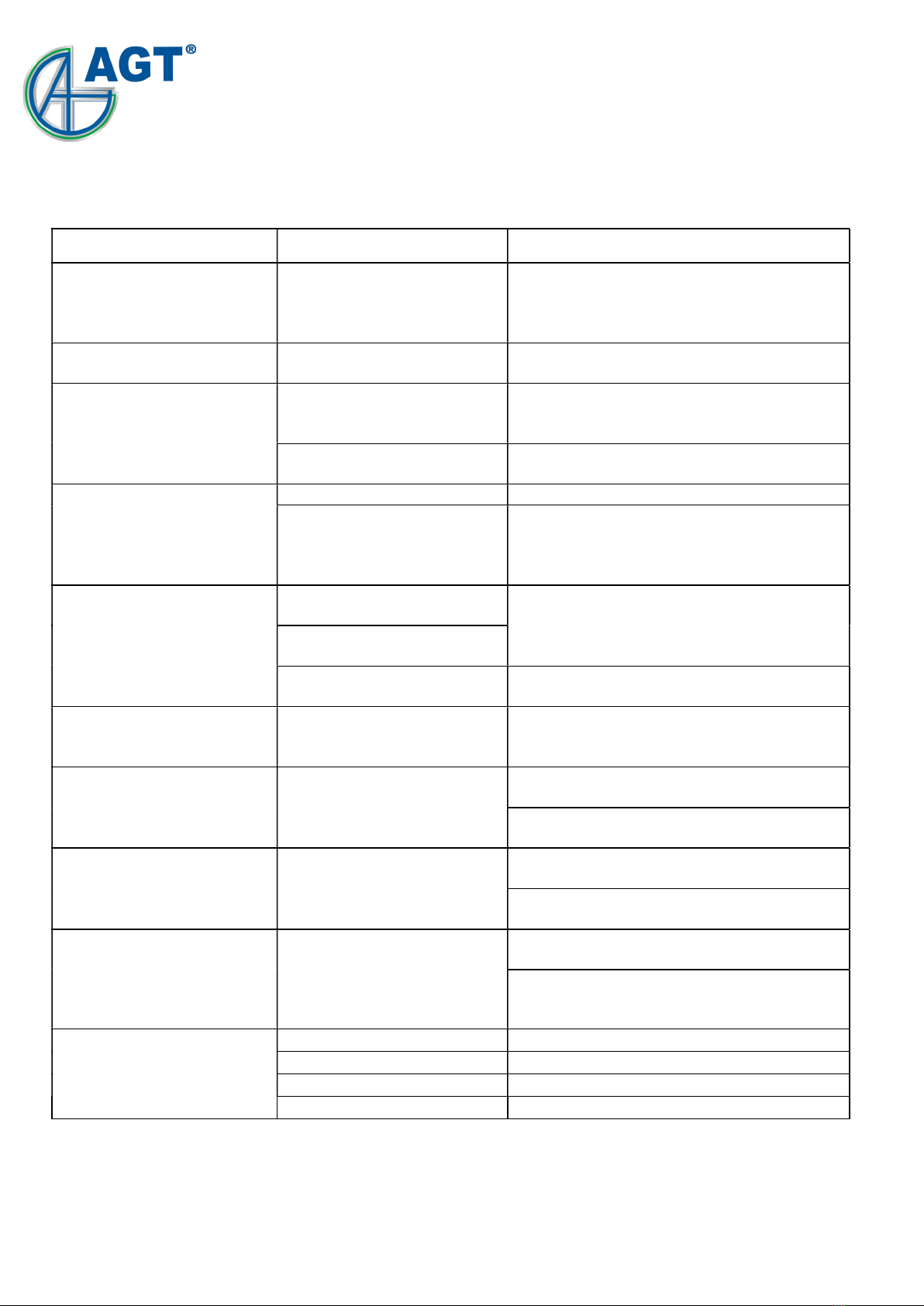

TROUBLE, CAUSE, SOLUTION

TROUBLE POSSIBLE CAUSE SOLUTION

Reduced speed or not

forward motion

Low oil level. Check the oil

level in the hydraulic pump

located in the handle

Put the handle on vertical position. Top the

oil until the level. Move the command lever

for several times (this operation helps

blowing the air out from the oil circuit)

The machine goes only

backward

The lip packing is broken or

weared Replace the lip packing

Low backward speed or

not speed at all

There’s too much oil in the

hydraulic pump located on

the handle

Fill out the oil in excess and restore the

level

There’s some air under

pressure in the pump

Open the pump’s cap to blow the

exceeding air out

The pump oil level

decreases during the time

The oil pipe leaks Replace the leaking parts

The seal of vibrating cylinder

is broken or weared and

spilling the oil inside the

vibrator

Replace the seal and top up the oil level

(pump and exciter)

The engine’s revs are

regular but the machine

does not vibrate

The transmission belt is

broken Replace the belt

The wear and tear has

caused the belt to loosen up

The centrifugal clutch has

broken Repair or replace the centrifugal clutch

The engine’s revs are low

but the exciter does not

stop

The centrifugal clutch has

broken Repair or replace the centrifugal clutch

Reduced or irregular speed

The engine revs are not

correct

Verify that during compaction gas lever is

at the max position

Reset the engine revs with proper

instrument

The engine works and the

exciter makes vibration but

the machine doesn’t work or

work in irregular way

Mechanical failure or

dismissing of eccentrically

weight

Open the exciter and remove the cause of

failure

Contact immediately AGT or any other

authorized centre

The engine does not work

properly, the clutch makes

smoke, the vibrator strains

The mechanicals parts of

vibrators do not work

properly (bearings are

weared and teared, lack of

oil, gears are broken)

Open the exciter and replace the weared

and teared parts

Contact immediately AGT or any other

authorized centre

The engine turns off or

does not work properly

Fuel tank empty Add fuel

Oil lack Add oil

Dirty air filter Clean air filter if necessary replace it

Engine damaged Contact an engine service center