Linhai LH1100U-D User manual

SERVICE MANUAL

LH1100U-D

2019.0

Foreword

This manual is designed primarily for use by the UTV factory certified service technicians in

a properly equipped shop. Persons using this manual should have a sound knowledge of

mechanical theory, tool use, and shop procedures in order to perform the work safely and

correctly. The technician should read the text and be familiar with service procedures

before starting the work. Certain procedures require the use of special tools. Use only the

proper tools, as specified. Cleanliness of parts and tools as well as the work area is of

primary importance.

This manual is divided into sections. Each section covers a specific UTV component or

system and, in addition to the standard service procedures. Keep this manual available for

reference in the shop area. When using this manual as a guide, the technician should use

discretion as to how much disassembly is needed to correct any given condition.

All references to left and right side of the vehicle are from the operator's perspective when

seated in a normal riding position.

At the time of publication all information contained in this manual was technically correct.

Some photographs used in this manual are used for clarity purposes only and are not

designed to depict actual conditions. We constantly refine and improve its products, all

materials and specifications are subject to change without notice.

This UTV’s publications and decals display the words Warning, Caution, Note, and At This

Point to emphasize important information:

WARNING

Indicates a potential hazard which will result in severe injury or death to the operator,

bystander or person inspecting or servicing the UTV.

CAUTION

Indicates a potential hazard which may result in personal injury or death or damage to the

machine.

NOTE

The word “NOTE” in this manual will alert you to key information or instructions.

CONTENTS

CHAPTER1 ………………………………………………General Information

↖

CHAPTER2 ………………………………………….……………Maintenance

↖

CHAPTER3…………………………………….………. ………………Chassis

↖

CHAPTER4…………………………………………..………………Final Drive

↖

CHAPTER5………………………………………………….……………Brakes

↖

CHAPTER6……………………………………………….………Transmission

↖

CHAPTER7…………………………………………Rear and Front Gearcase

↖

CHAPTER8………………………………………………….….………Electrical

↖

WARNING

Never run an engine in an enclosed area. Carbon monoxide exhaust gas is

poisonous and can cause severe injury or death. Always start engines outdoors.

Gasoline is extremely flammable and explosive under certain conditions. Battery

electrolyte is poisonous. It contains sulfuric acid. Serious burns can result from contact with

skin, eyes or clothing. Always keep alert and wear protection..

Exhaust system components are very hot during and after use of ATV. Never service

when the engine is warm or hot. Escaping steam from cooling system or hot oil from the

machine can cause severe burns. The engine must be cool before service.

Crate of the UTV and parts in the UTV maybe have sharp edge, always pay attention

and wear protection.

CHAPTER 1 GENERALINFORMATION LH1100U-D SERVICE MANUAL 2019.0

CHAPTER 1 GENERAL PAGE. 1-

1

CHAPTER 1 GENERAL INFORMATION

The parts of different types/ variants/ versions maybe un-interchangeable, even some parts have

almost same appearance. Always refer to Parts Manual of each UTV model for spare parts

information and service.

1.1 IMPORTANT INFORMAT ION

1.2 V.I.N AND ENGINE SERIAL NUMBER

1.3 VEHICLE DIMENSIONS

CHAPTER 1 GENERALINFORMATION LH1100U-D SERVICE MANUAL 2019.0

CHAPTER 1 GENERAL PAGE. 1-

2

1.1 IMPORTANT INFORMATION

PREPARATION FOR REMOVAL PROCEDURES

1. Remove all dirt, mud, dust and foreign material before removal and disassembly.

2. Use proper tools and cleaning equipment.

3. When disassembling the machine, always keep mated parts together. This includes gears,

cylinders, pistons and other parts that have been ”mated ”through normal wear. Mated part must

always be reused or replaced as an assembly.

4. During machine disassembly, clean all parts and place them in trays in the order of disassembly.

This will speed up assembly and allow for the correct installation of all parts.

5. Keep all parts away from any source of fire.

REPLACEMENT PARTS

Use only genuine parts for all replacements. Use recommended oil and grease for all lubrication

jobs. Other brands may be similar in function and appearance, but inferior in quality.

GASKETS,OIL SEALS AND O-RINGS

1. Replace all gaskets seals and O-rings when overhauling the engine. All gasket surfaces, oil seal

lips and O-rings must be cleaned.

2. Properly oil all mating parts and bearings during reassembly. Apply grease to the oil seal lips.

LOCK WASHERS/PLATES AND COTTER PINS

Replace all lock washers/plates and cotter pins

after removal. Bend lock tabs along the bolt or

nut flats after the bolt or nut has been tightened

to specification.

BEARINGS AND OIL SEALS

Install bearings and oil seals so that the

manufacturer’s marks or numbers are visible.

When installing oil seals, apply a light coating of

lightweight lithium base grease to the seal lips.

Oil bearings liberally when installing, if

appropriate.

1oil seal

CAUTION:

Do not use compressed air to spin the bearings

dry. This will damage the bearing surfaces.

1Bearing

CIRCLIPS

1. Check all circlips carefully before reassembly.

Always replace piston pin clips after one use.

CHAPTER 1 GENERALINFORMATION LH1100U-D SERVICE MANUAL 2019.0

CHAPTER 1 GENERAL PAGE. 1-

3

Replace distorted circlips. When installing a

circlip ①, make sure that the sharp-edged

corner ②is positioned opposite the thrust

③it receives. See sectional view.

④Shaft

CHECKING OF CONNECTIONS

Dealing with stains, rust, moisture, etc. on the

connector.

1. Disconnect:

Connector

2. Dry each terminal with an air blower.

3. Connect and disconnect the connector two or

three.

4. Pull the lead to check that it will not come off.

5. If the terminal comes off, bend up the pin ①

and reinset the terminal into the connector.

6. Connect:

Connector

NOTE:

The two connectors ” click ” together.

7. Check for continuity with a tester.

NOTE:

If there is no continuity, clean the terminals.

Be sure to perform the steps 1 to 7 listed

above when checking the wire harness.

Use the tester on the connector as shown.

Never run an engine in an enclosed area. Carbon monoxide exhaust gas is poisonous and can

cause severe injury or death. Always start engines outdoors.

Battery electrolyte is poisonous. It contains sulfuric acid. Serious burns can result from contact with

skin, eyes or clothing. Always keep alert and wear protection..

Exhaust system components are very hot during and after use of UTV. Never service when the

engine is warm or hot. Escaping steam from cooling system or hot oil from the machine can cause

severe burns. The engine must be cool before service.

Crate of the UTV and parts in the UTV maybe have sharp edge, always pay attention and wear

protection.

CHAPTER 1 GENERALINFORMATION LH1100U-D SERVICE MANUAL 2019.0

CHAPTER 1 GENERAL PAGE. 1-

4

CONVERSION TABLE

How to use the CONVERSION TABLE

Use this table to convert METRIC unit data to IMPERIAL unit data.

Ex.

METRIC MULIPLIER IMP

**mm x 0. 3937 = **in

**cm x 0.03937 = **in

CONVERSION TABLE

METRIC TO IMP

Known

Multiplier

Result

Torque

m·kg

m·kg

cm·kg

cm·kg

7.233

86.794

0.0723

0.8679

ft·lb

In·lb

ft·lb

In·lb

Weight

kg

g

2.205

0.03527

lb

oz

Distance

km/h

km

m

m

cm

mm

0.6214

0.6214

3.281

1.094

0.3927

0.03927

mph

mi

ft

yd

in

in

Volume/

Capacity

cc(cm3)

cc(cm3)

lit(liter)

lit(liter)

0.03527

0.06102

0.8799

0.2199

oz(IMP liq.)

cu·in

qt (IMP liq.)

gal(IMP liq.)

Miscellaneous

kg/mm

kg/cm2

Centigrade

55.997

14.2234

9/5(℃)+32

lb/in

psi(lb/in2)

Fahrenheit(°F)

CHAPTER 1 GENERALINFORMATION LH1100U-D SERVICE MANUAL 2019.0

CHAPTER 1 GENERAL PAGE. 1-

5

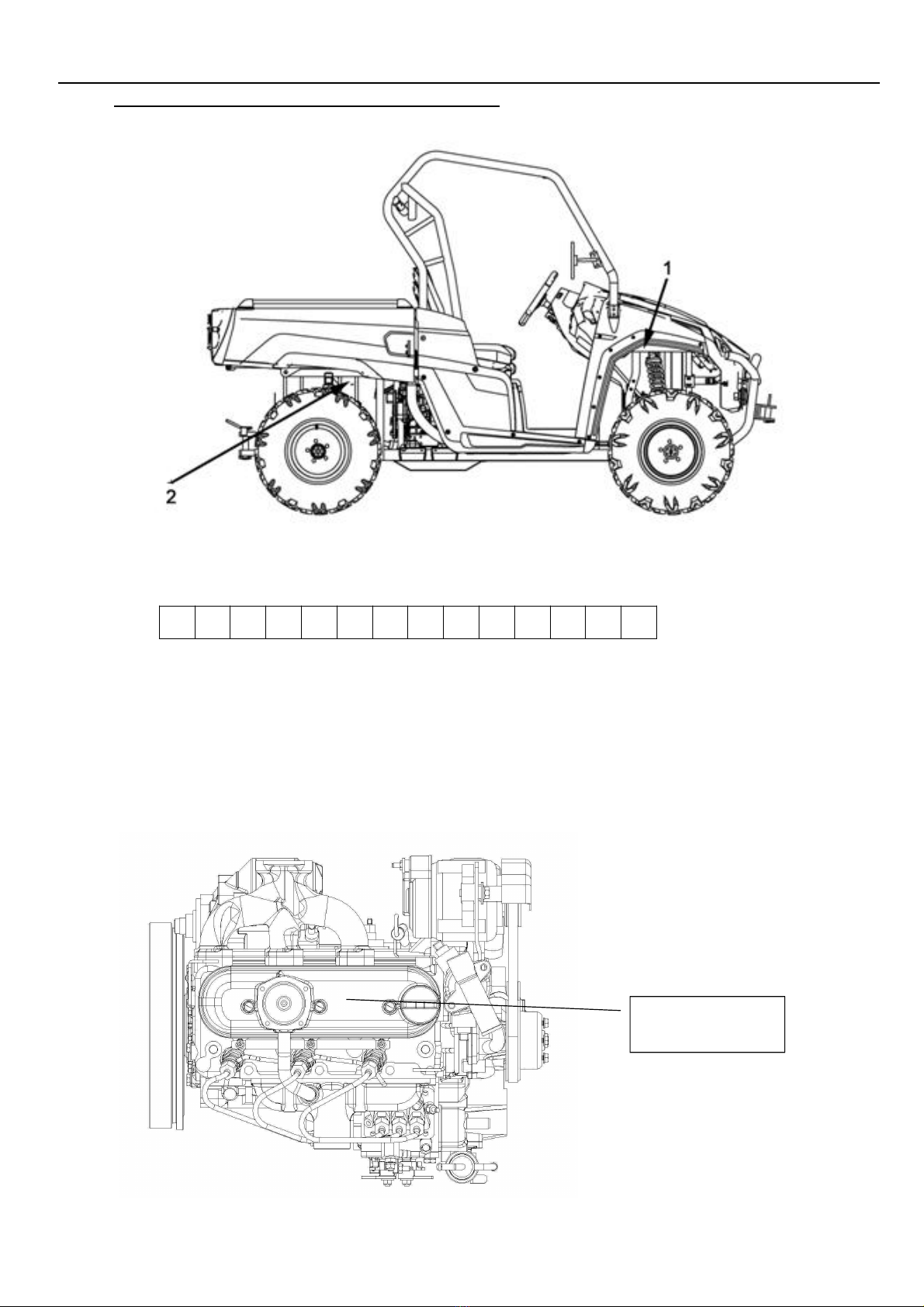

1.2 V.I.N AND ENGINE SERIAL NUMBER

Record the frame VIN and the engine serial number from your UTV in the spaces provided.

Frame VIN (found on the front right side of the frame tube)

The vehicle frame is important for model identification when registering your vehicle, obtaining

insurance or whenever replacement parts are required. In the event your vehicle were stolen these

numbers are essential to the recovery and identification of your UTV.

The engine serial numbers are punched on the surface of the crankcase

Engine number

CHAPTER 1 GENERALINFORMATION LH1100U-D SERVICE MANUAL 2019.0

CHAPTER 1 GENERAL PAGE. 1-

6

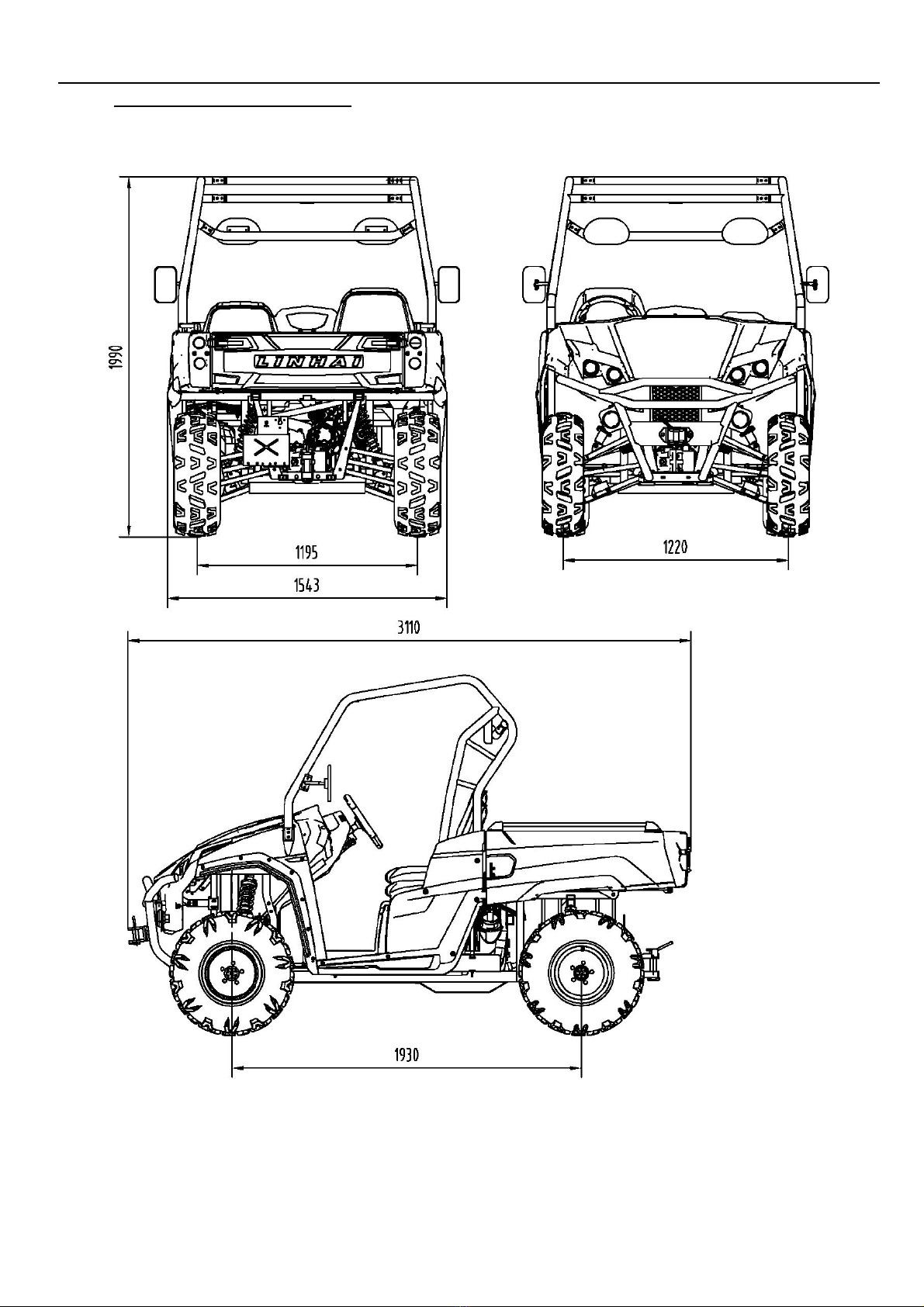

1.3 VEHICLE DIMENSIONS

CHAPTER 1 GENERALINFORMATION LH1100U-D SERVICE MANUAL 2019.0

CHAPTER 1 GENERAL PAGE. 1-

7

NOTES

CHAPTER 2 MAINTENANCE LH1100U-D SERVICE MANUAL 2019.0

CHAPTER 2 MAINTENANCE PAGE. 2-

1

CHAPTER 2 MAINTENANCE

The parts of different types/ variants/ versions maybe un-interchangeable, even some parts

have almost same appearance. Always refer to Parts Manual of each UTV model for spare

parts information and service.

2.1 PERIODIC MAINTENANCE

2.2 THROTTLE PEDAL INSPECTION

2.3 FUEL SYSTEM

2.4 TOE ALIGNMENT

2.5 BRAKING SYSTEM INSPECTION

2.6 SUSPENSION SPRING RPELOAD ADJ USTMENT

2.7 WHEELS

2.8 TIRE PRESSURE

2.9 FRAME, NUTS, BOLTS, FASTENERS

3.0 ST EERING COLUMN INSPECTION

CHAPTER 2 MAINTENANCE LH1100U-D SERVICE MANUAL 2019.0

CHAPTER 2 MAINTENANCE PAGE. 2-

2

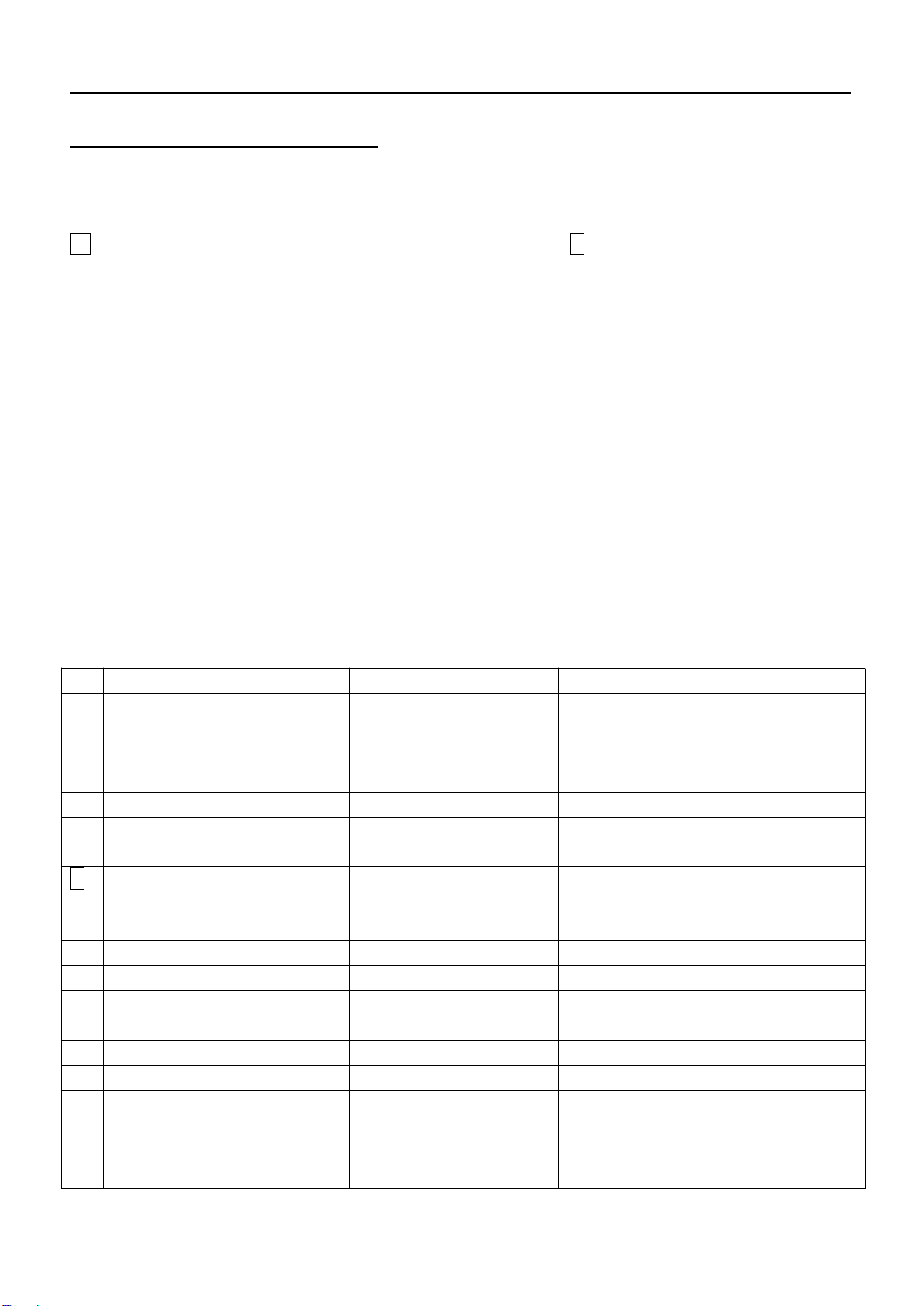

2.1 PERIODIC MAINTENANCE

GENARAL

CAUTION

Mark on the following chart

D:Dueto the nature of the adjustments marked withaD on the following chart, it is

recommended thatservice be performed by an authorized dealer.

▲:Service/Inspect more frequently when operating in adverse conditions.

PERIODIC MAINTENANCE SCHEDULE

Careful periodic maintenance will help keep your vehicle in the safest, most reliable condition.

Inspection, adjustment and lubrication intervals of important components are explained in the

following chart on the following pages.

Maintenance intervals are based upon average riding conditions and an average vehicle

speed of approximately 16km/h (10 miles per hour). Vehicles subjected to severe use, such

as operation in wet or dusty areas, should be inspected and serviced more frequently.

Inspect, clean, lubricate, adjust or replace parts as necessary.

NOTE: Inspection may reveal the need forreplacement parts.Always use genuine parts

available from your dealer.

Serviceandadjustments are critical. If you are not familiar with safe service and adjustment

procedures, have a qualified dealer perform these operations.

Item

Hours

Calendar

Remarks

Brake System

—

Pre-ride

Pre-ride inspection item

Accelerator pedal

—

Pre-ride

Pre-ride inspection item

Fuel System

—

Pre-ride

Check for leaks at tankcap, lines, fuel

pump, filter

Tires

—

Pre-ride

Inspect daily, pre-rideinspection item

Front and Rear Wheels/

Hubs/Fasteners

—

Pre-ride

Pre-ride inspection item

D

Steering

—

Pre-ride

Inspect daily, lubricate

Frame nuts, bolts

fasteners

—

Pre-ride

Pre-ride inspection item

Front Suspension

—

Pre-ride

Pre-ride inspection item

Rear Suspension

—

Pre-ride

Pre-ride inspection item

Brake Fluid Level

—

Pre-ride

Pre-ride inspection item

Engine Oil Level

—

Pre-ride

Check Level Daily

Air Filter / Pre-Filter

Daily

Inspect; clean often

Air Box Sediment Tube

Daily

Drain deposits whenevervisible

CoolantLevel

Daily

Check level daily, replace engine

coolant every one year

Head Lamp / Tail Lamp

Daily

Check operation daily;apply dielectric

greaseto connector when replaced

CHAPTER 2 MAINTENANCE LH1100U-D SERVICE MANUAL 2019.0

CHAPTER 2 MAINTENANCE PAGE. 2-

3

Item

Hours

When

Remarks

Air Filter-Main Element

Weekly

Inspect ; Replace ifnecessary

D

Brake Pad Wear / Parking

Brake Pads

10 hrs

Monthly

Inspect periodically

D

Front and rear axle boots

10 hrs

Monthly

Checkfor Axle boots,

looseness,damage, replace if necessary

Battery

20 hrs

Monthly

Check/clean Terminals

Engine Cylinder Head and

Cylinder Base Fasteners

25 hrs

3 months

Inspect (re-torque required at first

service only)

Engine mounts

25 hrs

3 months

Inspect

General Lubrication

50 hrs

3 months

Lubricate all grease fittings,

pivots, cables, etc.

Shift Linkage

50 hrs

6 months

Inspect, adjust

Front Suspension

50 hrs

6 months

Inspect, lubricate,tighten fasteners

Rear Suspension

50 hrs

6 months

Inspect, lubricate,tighten fasteners

D

Steering

50 hrs

6 months

Check operation and for looseness,

worn, damage, binding feeling / Adjust,

repair, Replace if necessary.

Front Prop Shaft, Shaft Yoke,

Boots

50 hrs

6 months

Inspect, lubricate, replace if necessary

Rear Prop Shaft, Shaft Yoke,

Boots

50 hrs

6 months

Inspect, lubricate, replace if necessary

D

Throttle Cable/ Accelerator

pedal

50 hrs

6 months

Inspect, adjust, lubricate, replace if

necessary

D

Drive belt

50 hrs

6 months

Inspect, replace ifnecessary

Coolant strength

50 hrs

6 months

Inspect strength seasonally

Cooling System hoses

50 hrs

6 months

Inspect/replace ifnecessary

Rear Gear case Oil

100 hrs

Monthly

Check monthly and changeannually

Front Gear case Oil

100 hrs

Monthly

Check monthly and changeannually

Oil Filter

Every

100 hrs

2000 km or 6

months

Oil filter replacement at the above

intervals, should be done together with

the engine oil change

EngineOil-Level/Change

Every

100 hrs

2000 km or

6months

Check Level Daily; Break-in Service at

200Km (1month). Change oil more often

in cold weather use.

D

Parking Brake Cable

Adjustment

100 hrs

6 months

Inspect, adjust tension as needed

D

Fuel System

100 hrs

12 months

Check for leaks at tankcap, lines, fuel

pump, replace fuel lines annually

D

Wheels bearings

100 hrs

12 months

Inspect, replace if necessary

Radiator

100 hrs

12 months

Inspect, clean

D

Fuel Filter

100 hrs

12 months

Replace annually

CHAPTER 2 MAINTENANCE LH1100U-D SERVICE MANUAL 2019.0

CHAPTER 2 MAINTENANCE PAGE. 2-

4

Item

Hours

When

Remarks

Transmission Oil Level

100hrs

Monthly

Check monthly and changeannually

Spark Plug

100 hrs

12 months

Inspect-replace ifnecessary

Shock

100 hrs

Inspect seals

D

Brake Fluid

200 hrs

24 months

Change every tow years

Spark arrestor

300 hrs

36 months

Clean out, replace ifnecessary

D

Toe adjustment

As

required

As required

Periodic inspection,

adjust when parts are

replaced

Headlight Aim

As

required

As required

Adjust if necessary

LUBRICATION RECOMMENDATIONS

Item

Lube Rec

Method

Frequency

1.Engine Oil

API CH-4 SAE

15W-40

Add to properlevel on dipstick

Check level daily

2.Brake Fluid

DOT 3 Only

Maintain level between fill lines.

As require;

changeevery two

years or 200 hours

3.Rear Gear case oil

SAEGL-4 85W/90

Add to properlevel

Change annually orat

100 hours

4.Front Gear case oil

SAE GL-4 85W/90

Add to properlevel

Change annually or at

100 hours

5.Steering system

Grease

Lubricate the pivoting and sliding

parts

Every 3 months or50

hours

6.Tie rods

Grease

Grease

Semi-annually

7.ShiftLinkages

Grease

Locate fittingsand Grease

Semi-annually

8.Ball joints

Grease

Inspect, Locate fittingsand

Grease, or replace it if necessary

Semi-annually

9.Prop Shaft &Shaft

Yoke, Spline Joint

Grease

Locate fitting and Grease

Semi-annually or 50

hours

10.Front/RearA-arm

Grease

Locate fitting onpivot shaft

andgrease with grease gun

Semi-annually or 50

hours

11.ThrottleCable

Grease M

Grease, inspectand replace it

ifnecessary

Semi-annually or 50

hours

12.Acceleratorpedal

and brake pedal

Grease

Grease, inspect

Semi-annually or 50

hours

NOTE:

1. More often under severe use, such as wet or dusty conditions .

2. Grease: Light weight lithium-soap grease.

3. Grease M:molybdenum disulfide(MoS2) grease(water resistant).

4. *When suspension action becomes stiff or after washing.

5. Hours are based on 10 mph(16Km/h) average.

CHAPTER 2 MAINTENANCE LH1100U-D SERVICE MANUAL 2019.0

CHAPTER 2 MAINTENANCE PAGE. 2-

5

2.2 THROTTLEPEDAL INSPECTION

THROTTLE FREEPLAY

If the throttle pedal has excessive play due to cable

stretch or cable misadjustment, it will cause a delay

in throttle speed. Also, the throttle may not open fully.

If the throttle pedal has no play, the throttle may be

hard to control, and the idle speed may be erratic.

Check the throttle pedal play periodically in

accordance with the Periodic Maintenance Chart

and adjust the play if necessary.

THROTTLE FREEPLAY INSPECTION

1. Apply the parking brake.

2. Put the gear shift lever in the P(Park) position.

3. Start the engine, and warm it up thoroughly.

4. Measure the distance the throttle pedal moves

before the engine begins to pick up speed. Free

play should be 1.5 –3 mm.

Adjustment

1. Slide the boot off inline cable adjuster sleeve.

Loosen adjuster locknut.

2. Turn adjuster until 1.5 to 3 mm, freeplay is

achieved pedal. NOTE: While adjusting freeplay,

it is important you flip the throttle lever back and

forth.

3. Tighten locknut.

2.3 FUELSYSTEM

Always stop the engine and refuel outdoors or in a well ventilated area.

Do not smoke or allow open flames or sparks in or near the area where refueling is

performed or where gasoline is stored.

Do not overfill the tank. Do not fill the tank neck.

If you get fuel in your eyes or if you swallow gasoline, see your doctor immediately.

If you spill fuel on your skin or clothing, immediately wash it off with soap and water and

change clothing.

Never start the engine or let it run in an enclosed area. Fuel powered engine exhaust

fumes are poisonous and can cause loss of consciousness and death in a short time.

Never drain the float bowl when the engine is hot. Severe burns may result.

CHAPTER 2 MAINTENANCE LH1100U-D SERVICE MANUAL 2019.0

CHAPTER 2 MAINTENANCE PAGE. 2-

6

FUEL LINES

1. Check fuel lines for signsof wear,

deterioration, damage or leakage.

Replace if necessary.

2. Be sure fuel lines are routed

properly and secured with cable

ties.

CAUTION:

Make sure lines are not kinked

orpinched.

Replace all fuel lines every two years.

2.4TOEALIGNMENT

METHOD: STRAIGHTEDGE OR STRING

Be sure the steering wheel in astraight ahead position.

NOTE:Stringshould just touchside surfaceof reartire on

each sideof the UTV.

Measure from stringto rim at front andrear ofrim.

Rear rim measurement (A) should be 1/8" to 1/4" (3 to 6

mm) morethan front rimmeasurement (B).

Always pay attention to tie rods assembly, Both endsmust

screw in same and enough threads length.

2.5BRAKING SYSTEM INSPECTION

CHAPTER 2 MAINTENANCE LH1100U-D SERVICE MANUAL 2019.0

CHAPTER 2 MAINTENANCE PAGE. 2-

7

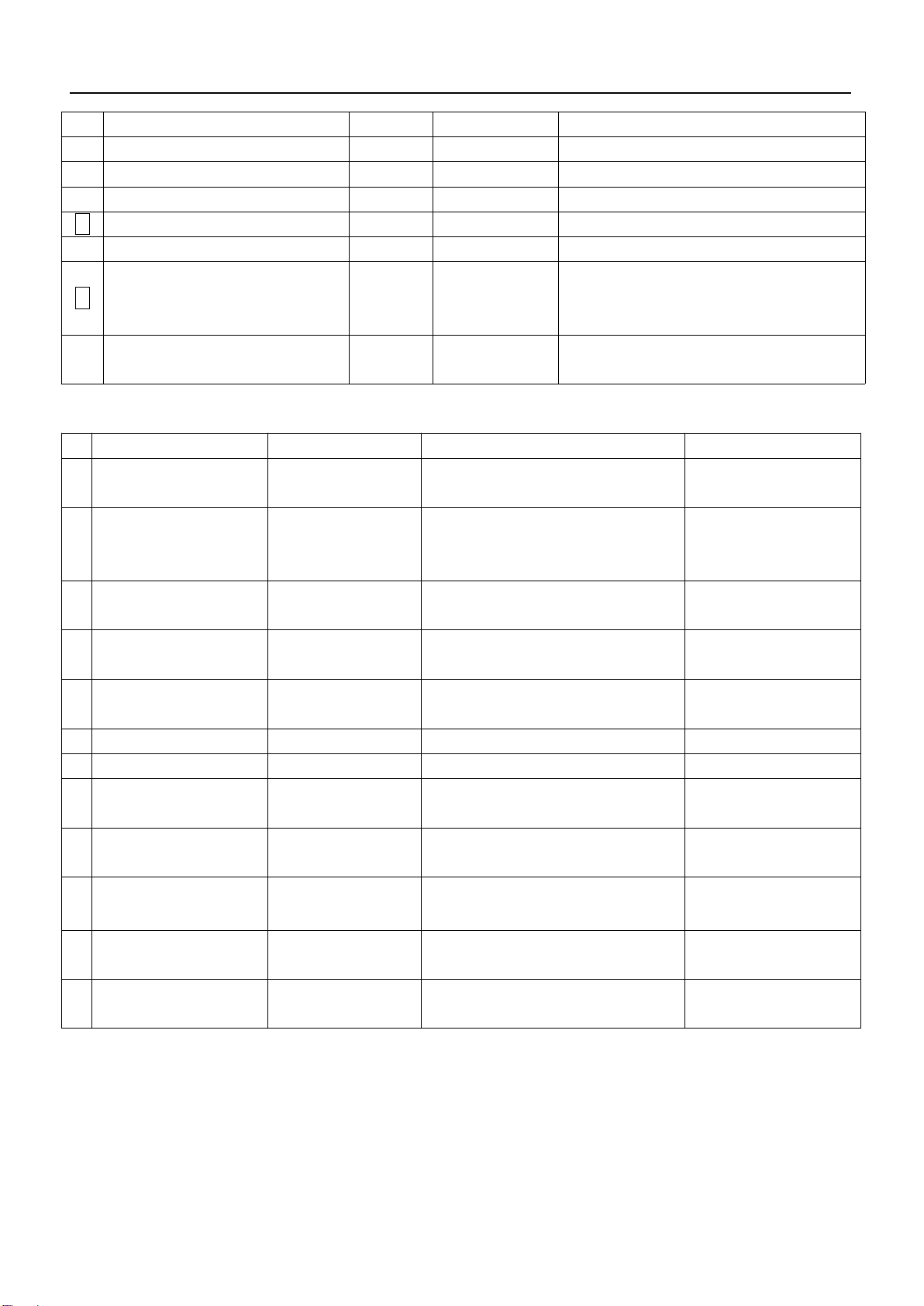

The following checks are recommended to keep the

braking system in good operating condition. Service

life of braking system componentsdepends on

operating conditions. Inspect brakes in accordance

with the maintenance schedule and before each ride

Keep fluid level in the master cylinder reservoirto

the indicated level on reservoir.

Use DOT 3 brake fluid.

NOTE: Use new brake fluid or brake fluid from a

sealed container to avoid contamination to system.

Check brake system for fluid leaks.

Check brake for excessive travel or spongy feel.

Check friction pads for wear, damage and looseness.

Check surface condition of the disc.

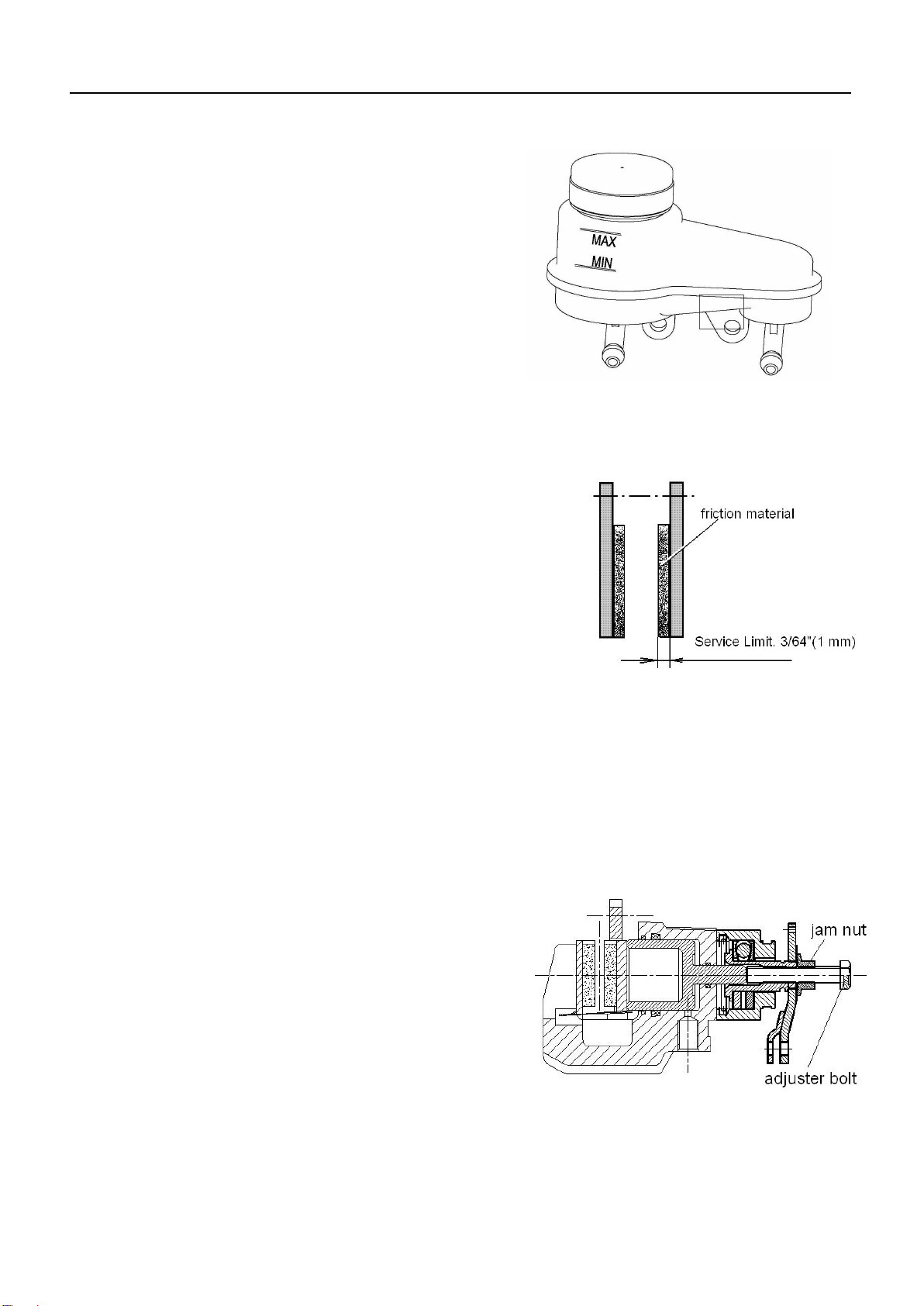

BRAKEPADINSPECTION

Pads should be changed when friction material is

worn to 3/64" (1mm).

HOSE/FITTINGINSPECTION

Check braking system hoses and fittings for cracks,

deterioration, abrasion, and leaks. Tighten any loose

fittings and replace any worn or damaged parts.

ADJUSTING THE BRAKE PEDAL

Check the brake pedal free play. Free play should be

8 –12mm. Outof specification →Adjust.

1. Loosen the locknut

2. Turn brake rod in or out until the correctfree play

is obtained.

3. Tighten the locknut

ADJUSTING THE PARKING BRAKE

Although the parking brake has beenadjusted at the

factory,the brake should be checked for proper

operation. Themechanical brake must be

maintained to be fullfunctional.

1. With the engine off, apply theparking brake lever

and attempt to move the UTV.

2. If the rear wheels are locked, it is adjusted

properly.

3. If thewheels are not locked, it must beadjusted.

To adjust (set up) the mechanical parking brake,

use thefollowing procedure

CHAPTER 2 MAINTENANCE LH1100U-D SERVICE MANUAL 2019.0

CHAPTER 2 MAINTENANCE PAGE. 2-

8

Note: The adjusting on the caliper is for the wear out

of the pads.

1. With the engine off, loosen the adjustor on the lever.

2. Loosen the jam nut of the adjuster on the caliper.

3. Turn the adjuster (bolt) CW (clockwise) by handtill the

pad touch the brake disc, turn the adjuster bolt CCW

(counterclockwise) by 1/4 to one turn for 10 to20mm

freeplay at the end of the parking lever.

4. Tighten the jam nuts securely against theadjusters.

5. Make sure the rear wheels turns freely without

dragging.

6. Turn the adjustor (the one on the lever) and apply the

lever. While adjusting,it is important you apply the

lever back and forthfor operation, free play and the

locking of the parking position.

7. Make sure the rear wheels turns freely without

dragging and parking brake works properly.

8. Field test for parking. It must be capable of holding

the laden UTV stationary on an 18% up and down

gradient.

A temporary adjusting can also be done to the brake

cable on the parking lever side by turn the adjuster

(nut) directly. But the adjust range is limited. Always do

the procedure 1 to 8 when necessary.

2.6SUSPENSION SPRING RPELOAD ADJUSTMENT

Operator weight and vehicle loading affect

suspensionspring preload requirements. Adjust as

necessary.

Compress and releasesuspension. Damping should

be smooth throughout the range of travel. Check

allsuspension componentsforwear or damage.

Inspect shockfor leakage

The front shock spring are adjustable. Rotate the

adjuster cam either direction to increase or decrease

spring tension. Always adjust both left and right sides

equally.

2.7 WHEELS

Inspect all wheels for runout of damage.

Check wheel nuts and ensure they are tight.

CHAPTER 2 MAINTENANCE LH1100U-D SERVICE MANUAL 2019.0

CHAPTER 2 MAINTENANCE PAGE. 2-

9

Do not over tighten the wheel nuts.

WHEEL REMOVAL

1. Stop the engine, place the transmission in gear and

lock the parking brake.

2. Loosen the wheel nuts slightly.

3. Elevate the side of the vehicle by placing a suitable

stand under the footrest frame.

4. Remove the wheel nuts and remove the wheel.

WHEEL INSTALLATION

1. With the transmission in gear and the parking

Brake locked, place the wheel in the correct

Position on the wheel hub. Be sure the valve

stem is toward the outside and rotation arrows

on the tire point toward rotation.

2. Attach the wheel nuts and finger tighten them.

Install as shown for front or rear wheels.

3. Lower the vehicle to the ground.

4. Securely tighten the wheel nuts to the proper

Torque listed in the table. On wheel nuts, Make

sure tapered end of nut goes into taper on

wheel.

Wheel Nut Torque Specifications

CAUTION:If wheels are improperly installed it could

affect Vehicle handling and tire wear.

2.8TIRE PRESSURE

TIRE INSPECTION

CAUTION:

Bolt Size

Specification

Front M12X1.25

69Ft.Lbs

95Nm

Rear M12X1.25

69Ft.Lbs

95Nm

CHAPTER 2 MAINTENANCE LH1100U-D SERVICE MANUAL 2019.0

CHAPTER 2 MAINTENANCE PAGE. 2-

10

Maintain proper tire pressure. Refer to the warning

tire pressure decal applied to the vehicle.

Improper tire inflation may affect UTV

maneuverability.

When replacing a tire always use original

equipment size and type and replace in pairs.

The use of non- standard size or type tires may

affect UTV handling and cause machine damage.

TIRE TREAD DEPTH

Always replace tires when tread depth is worn to 1/8"

(3mm ) or less.

Operating an UTV with worn tires will increase the

possibility of the vehicle skidding easily with possible

loss of control.

Worn tires can cause an accident.

Always replace tires when the tread depth measures

1/8" (3mm ) or less.

2.9FRAME , NUTS, BOLTS, FASTENERS

Periodically inspect the tightness of all fasteners in

accordance with the maintenance schedule. Check that

all cotter pins are in place. Refer to specific fastener

torques listed in each chapter.

3.0STEERING COLUMN INSPECTION

When assemble the steering column, check the

direction of the column.

Tire Pressure Inspection

Front

Rear

14PSI(97±0.5KPa)

14PSI(97±0.5KPa)

This manual suits for next models

1

Table of contents