LinMot C1150-PN-XC-0S User manual

August 2019

Documentation of the PROFINET Interface of the following

Drives:

·

C1150-PN-XC-0S/1S

·

C1250-PN-XC-0S/1S

·

C1450-PN-VS-0S/1S

·

E1450-PN-QN-0S/1S

·

E1250-PN-UC

Manual

PROFINET Interface

Doc.: 0185-1090-E_4V9_MA_PROFINET

© 2019 NTI AG

This work is protected by copyright.

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or

mechanical, including photocopying, recording, microfilm, storing in an information retrieval system, not even

for didactical use, or translating, in whole or in part, without the prior written consent of NTI AG.

LinMot® is a registered trademark of NTI AG.

Note

The information in this documentation reflects the stage of development at the time of press and is therefore

without obligation. NTI AG reserves itself the right to make changes at any time and without notice to reflect

further technical advance or product improvement.

NTI AG

LinMot

Bodenaeckerstrasse 2

CH-8957 Spreitenbach

Tel.: +41 56 419 91 91

Fax.: +41 56 419 91 92

Email: off[email protected]

Homepage: www.LinMot.com

Page 3 of 21

NTI AG / LinMot

Table of Contents

1 System overview ..................................................................................................................................... 4

1.1 References .......................................................................................................................................... 4

1.2 Port assignement ................................................................................................................................ 4

2 Setup in a PLC ......................................................................................................................................... 5

2.1 Create a new Project ........................................................................................................................... 5

2.2 Configure PLC Device ......................................................................................................................... 5

2.3 Configure LinMot Drive ........................................................................................................................ 7

3 Process Data Object (PDO) Configuration .......................................................................................... 13

3.1 Bidirectional PDO Modules ............................................................................................................... 13

3.1.1 Default IO mapping with Config .................................................................................................. 13

3.1.1.1 Output Data ........................................................................................................................... 13

3.1.1.2 Input Data .............................................................................................................................. 13

3.1.2 Control/Status ............................................................................................................................. 14

3.1.2.1 Output Data ........................................................................................................................... 14

3.1.2.2 Input Data .............................................................................................................................. 14

3.1.3 Real Time Config ........................................................................................................................ 14

3.1.3.1 Output Data ........................................................................................................................... 14

3.1.3.2 Input Data .............................................................................................................................. 14

3.2 Output PDO Modules ........................................................................................................................ 15

3.2.1 MC Interface ............................................................................................................................... 15

3.2.2 NC Setpoint Values ..................................................................................................................... 15

3.3 Input PDO Modules ........................................................................................................................... 15

3.3.1 Get StateVar ............................................................................................................................... 15

3.3.2 Get Actual Position ...................................................................................................................... 15

3.3.3 Get Demand Position .................................................................................................................. 16

3.3.4 Get WarnWord ............................................................................................................................ 16

3.3.5 Get ErrorCode ............................................................................................................................. 16

3.3.6 Get Current 32b .......................................................................................................................... 16

3.3.7 Mon Channel 1 ............................................................................................................................ 16

3.3.8 Mon Channel 2 ............................................................................................................................ 16

3.3.9 Mon Channel 3 ............................................................................................................................ 16

3.3.10 Mon Channel 4 .......................................................................................................................... 17

3.3.11 Get Current 16b ........................................................................................................................ 17

4 PROFINET Parameters .......................................................................................................................... 18

4.1 Parameters ........................................................................................................................................ 18

4.1.1 ProfiNet\Dis-/Enable .................................................................................................................... 18

4.1.2 ProfiNet\Byte/Word Order\Byte Order ......................................................................................... 18

4.1.3 ProfiNet\Byte/Word Order\Word Order ....................................................................................... 18

4.1.4 ProfiNet\Byte/Word Order\MC CMD Intf Par Order .................................................................... 18

4.1.5 ProfiNet\Monitoring Channels ..................................................................................................... 18

5 Connecting to the PROFINET Network ............................................................................................... 20

5.1 Pin Assignment of the Connectors X17-X18 ..................................................................................... 20

Page 4 of 21 NTI AG / LinMot

1 System overview

PROFINET is the open real-time Ethernet network, in this manual the LinMot profile drives are described.

The LinMot drives act as slave in this network and is implemented with the TPS1 chip from Renesas.

For further information on the PROFINET fieldbus protocols please visit:

http://www.profibus.com/

Programming examples provided by LinMot are listed under: http://www.linmot.com/index.php?id=141

1.1 References

All user manuals are distributed with the LinMot-Talk software the newest versions can be downloaded from

the LinMot homepage in the download section.

Ref

Title

Source

1

User Manual Motion Control SW

www.linmot.com

2

LinMot Drive Configuration over Fieldbus Interfaces SG5

www.linmot.com

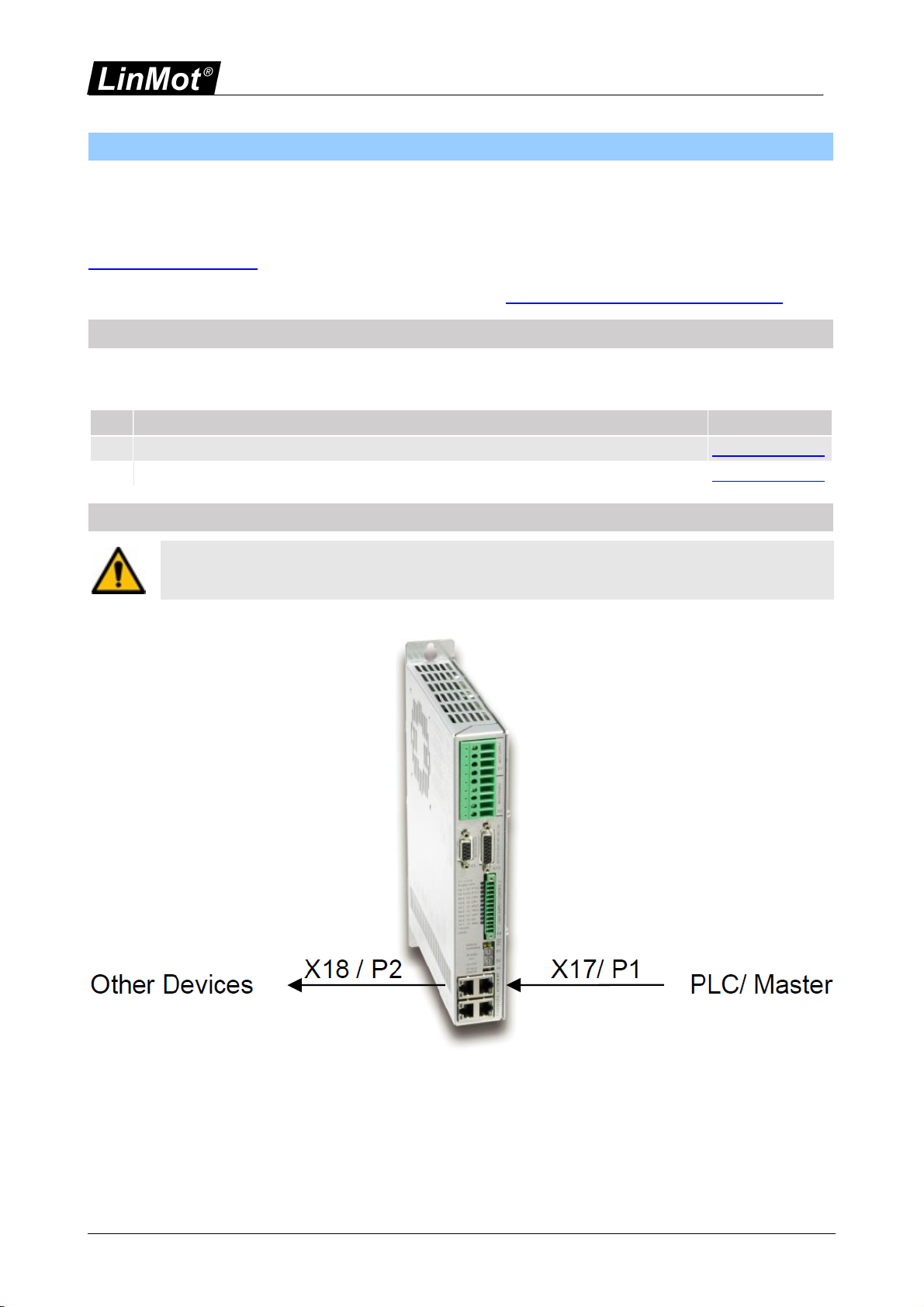

1.2 Port assignement

Attention: Within the PROFINET network normally the topology is defined, for easy setup and

replacement of devices. The real time Ethernet RJ45 connector X17 is the P1 port and the real

time RJ45 connector X18 is the P2 port in this context.

Page 5 of 21

NTI AG / LinMot

2 Setup in a PLC

In the following steps the integration of a LinMot EtherCAT Servo Drive in the PLC is described. In the

example a SIEMENS Simatic S7-1500 PLC and a LinMot C1150-PN-XC drive with a PnP capable motor is

used. It is assumed that PLC and Drive are powered and connected to each other.

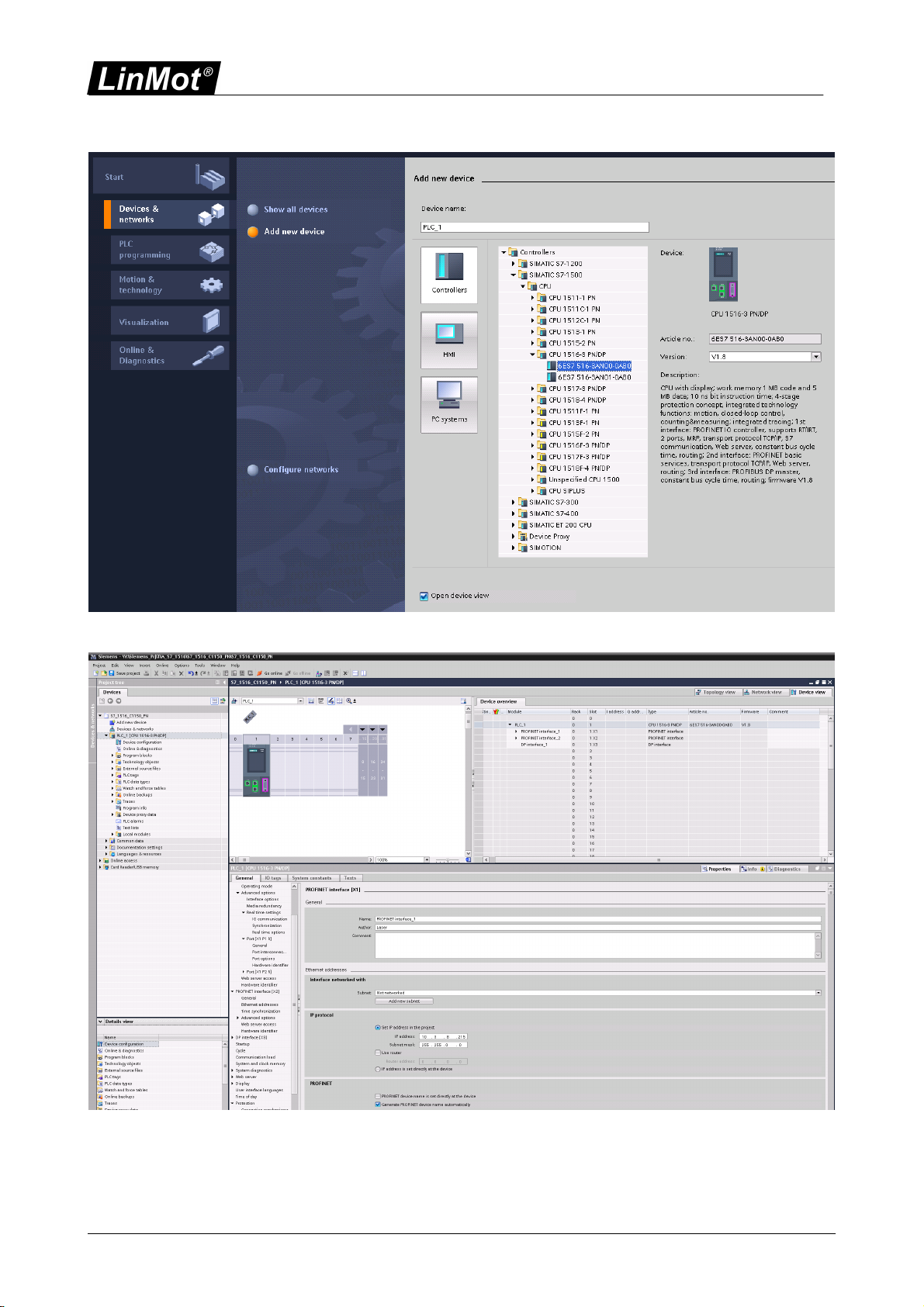

2.1 Create a new Project

create new protject

2.2 Configure PLC Device

Configure used PLC device

Page 6 of 21 NTI AG / LinMot

Select PLC device.

Configure the PROFINET, set the PLC network address.

Page 7 of 21

NTI AG / LinMot

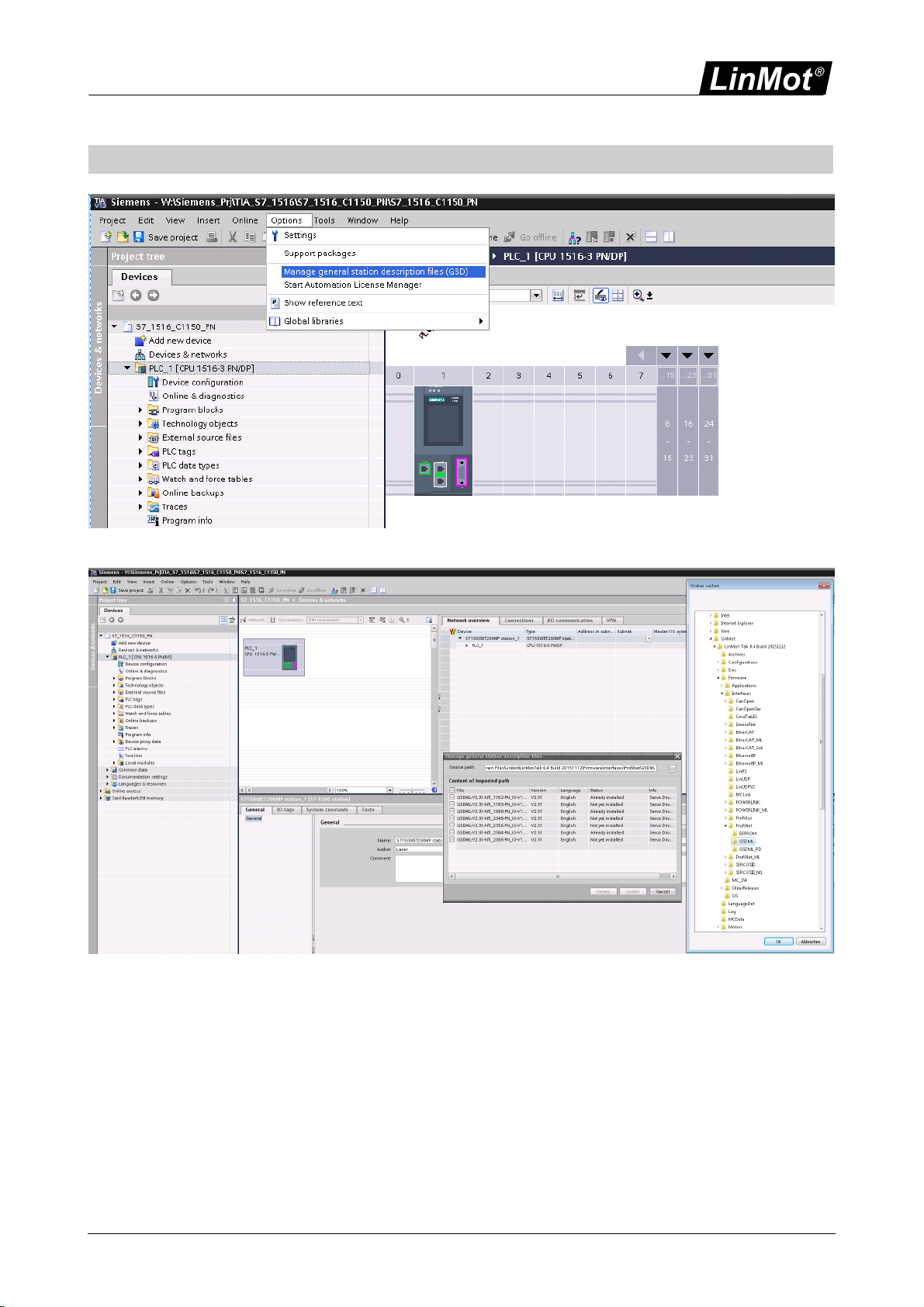

2.3 Configure LinMot Drive

If not installed already install linMot GSD-file.

Select Installation path of the MinMot GSD-files.

Page 8 of 21 NTI AG / LinMot

Select wanted device.

Page 9 of 21

NTI AG / LinMot

In the Hardware catalog select desired device.

Page 10 of 21 NTI AG / LinMot

Drag and drop it frpm the hardware catalog to the network view.

Connect the PROFINET of the drive to the PLC.

In the Topology view define the connection topology

Page 11 of 21

NTI AG / LinMot

Configure the network address of the drive.

By default in slot 1 of the PN-IO communication the “Default IO mapping with Config” is plugged, which is

suitable for most applications.

Compile the Configuration by pressing the button.

Page 12 of 21 NTI AG / LinMot

Download the configuration

After the successful download of the configuration the PROFINET IO communication should be established

and the green realtime bus LED on the drive is on.

Page 13 of 21

NTI AG / LinMot

3 Process Data Object (PDO) Configuration

The cyclic process data is configured in the master and transmitted to the slave during startup. The data

Object modules could be configured by trag and trop to the device slots 1..15.

Overview of the supported Process Data Objects Modules

By default the module ”Default IO mapping with Config” is plugged into Slot 1, with this module most

application should be well supported.

3.1 Bidirectional PDO Modules

3.1.1 Default IO mapping with Config

3.1.1.1 Output Data

Index

Size

[Byte]

Byte

Offset

Name

Data

Type

Tlg 16

32

-

Variables

RECORD

1

2

0

ControlWord

Word16

2

2

2

Motion Command Header

Word16

3,4

4

4

Motion Command parameter 1

Word32

5,6

4

8

Motion Command parameter 2

Word32

7,8

4

12

Motion Command parameter 3

Word32

9,10

4

16

Motion Command parameter 4

Word32

11,12

4

20

Motion Command parameter 5

Word32

13

2

24

Config Header

Word16

14

2

26

Config Index

Word16

15,16

4

28

Config Value

Word32

For the meaning oft he „Control Word“ and the „Motion Command interface“ refer to [1], for the „Real Time

Config Interface“ refer to [2].

3.1.1.2 Input Data

Index

Size

[Byte]

Byte

Offset

Name

Data

Type

Tlg 16

26

-

Variables

RECORD

Page 14 of 21 NTI AG / LinMot

Index

Size

[Byte]

Byte

Offset

Name

Data

Type

1

2

0

StateVar

Word16

2

2

2

StatusWord

Word16

3

2

4

WarnWord

Word16

4,5

4

6

Demand Position

Word32

6,7

4

10

Actual Position

Word32

8,9

4

14

Demand Current

Word32

10

2

18

Config Status Word

Word16

11

2

20

Config Index Response

Word16

12,13

4

22

Config Value Response

Word32

For the meaning of the variables 1-6 refer to [1], for the „Real Time Config Interface“ refer to [2].

3.1.2 Control/Status

3.1.2.1 Output Data

Index

Size

[Byte]

Byte

Offset

Name

Data

Type

Tlg 1

2

-

Variables

RECORD

1

2

0

ControlWord

Word16

3.1.2.2 Input Data

Index

Size

[Byte]

Byte

Offset

Name

Data

Type

Tlg 1

2

-

Variables

RECORD

1

2

0

StatusWord

Word16

3.1.3 Real Time Config

For the meaning of the „Real Time Config Interface“ refer to [2].

3.1.3.1 Output Data

Index

Size

[Byte]

Byte

Offset

Name

Data

Type

Tlg 4

8

-

Variables

RECORD

1

2

0

Config Header

Word16

2

2

2

Config Index

Word16

3,4

4

4

Config Value

Word32

3.1.3.2 Input Data

Index

Size

[Byte]

Byte

Offset

Name

Data

Type

Tlg 4

26

-

Variables

RECORD

1

2

0

Config Status Word

Word16

Page 15 of 21

NTI AG / LinMot

Index

Size

[Byte]

Byte

Offset

Name

Data

Type

2

2

2

Config Index

Word16

3,4

4

4

Config Value Response

Word32

3.2 Output PDO Modules

3.2.1 MC Interface

Index

Size

[Byte]

Byte

Offset

Name

Data

Type

Tlg 3

22

-

Variables

RECORD

2

2

0

Motion Command Header

Word16

3,4

4

2

Motion Command parameter 1

Word32

5,6

4

6

Motion Command parameter 2

Word32

7,8

4

10

Motion Command parameter 3

Word32

9,10

4

14

Motion Command parameter 4

Word32

11,12

4

18

Motion Command parameter 5

Word32

3.2.2 NC Setpoint Values

Index

Size

[Byte]

Byte

Offset

Name

Data

Type

Tlg 15

12

-

Variables

RECORD

1,2

4

0

Position Setpoint

Word32

3,4

4

4

Velocity Setpoint

Word32

5,6

4

8

Acceleration Setpoint

Word32

3.3 Input PDO Modules

3.3.1 Get StateVar

Index

Size

[Byte]

Byte

Offset

Name

Data

Type

Tlg 2

2

-

Variables

RECORD

1

2

0

StateVar

Word16

3.3.2 Get Actual Position

Index

Size

[Byte]

Byte

Offset

Name

Data

Type

Tlg 5

4

-

Variables

RECORD

1

4

0

Actual Position

Int32

Page 16 of 21 NTI AG / LinMot

3.3.3 Get Demand Position

Index

Size

[Byte]

Byte

Offset

Name

Data

Type

Tlg 6

4

-

Variables

RECORD

1

4

0

Demand Position

Int32

3.3.4 Get WarnWord

Index

Size

[Byte]

Byte

Offset

Name

Data

Type

Tlg 7

2

-

Variables

RECORD

1

2

0

WarnWord

Word16

3.3.5 Get ErrorCode

Index

Size

[Byte]

Byte

Offset

Name

Data

Type

Tlg 8

2

-

Variables

RECORD

1

2

0

ErrorWord

Word16

3.3.6 Get Current 32b

Index

Size

[Byte]

Byte

Offset

Name

Data

Type

Tlg 9

4

-

Variables

RECORD

1

4

0

Demand Current

Int32

3.3.7 Mon Channel 1

Index

Size

[Byte]

Byte

Offset

Name

Data

Type

Tlg 10

4

-

Variables

RECORD

1

4

0

Monitoring Channel 1

Word32

3.3.8 Mon Channel 2

Index

Size

[Byte]

Byte

Offset

Name

Data

Type

Tlg 11

4

-

Variables

RECORD

1

4

0

Monitoring Channel 2

Word32

3.3.9 Mon Channel 3

Index

Size

[Byte]

Byte

Offset

Name

Data

Type

Tlg 12

4

-

Variables

RECORD

1

4

0

Monitoring Channel 3

Word32

Page 17 of 21

NTI AG / LinMot

3.3.10 Mon Channel 4

Index

Size

[Byte]

Byte

Offset

Name

Data

Type

Tlg 13

4

-

Variables

RECORD

1

4

0

Monitoring Channel 4

Word32

3.3.11 Get Current 16b

Index

Size

[Byte]

Byte

Offset

Name

Data

Type

Tlg 14

2

-

Variables

RECORD

1

2

0

Demand Current

Int16

Page 18 of 21 NTI AG / LinMot

4 PROFINET Parameters

4.1 Parameters

Attention:

Profinet), which can be configured with the distributed LinMot-Talk software.

With these parameters, the PROFINET behaviour can be configured. The LinMot-Talk software can be

downloaded from http://www.linmot.com under the section download, software & manuals.

4.1.1 ProfiNet\Dis-/Enable

With the Dis-/Enable parameter the LinMot Servo Drive can be run without the Ethernet PROFINET Interface

going online. So in a first step the system can be configured and run without any bus connection.

PROFINET\Dis-/Enable

Disable

Servo Drive runs without PROFINET.

Enable

Servo Drive runs with PROFINET connection.

IMPORTANT: If the PROFINET Interface is disabled, the integrated TPS1-ASIC rests in reset state! No

messages will be sent to other devices connected to the PROFINET-Network via the servo drive.

4.1.2 ProfiNet\Byte/Word Order\Byte Order

Defines the used byte order.

PROFINET\Byte/Word Order\Byte Order

Reversed

Byte order is reversed. For S7 PLCs select reversed.

Not reversed

Byte order is not reversed.

4.1.3 ProfiNet\Byte/Word Order\Word Order

Defines the used word order.

PROFINET\Byte/Word Order\Word Order

Reversed

Word order is reversed.

Not reversed

Word order is not reversed.

4.1.4 ProfiNet\Byte/Word Order\MC CMD Intf Par Order

Defines the used parameter word order.

PROFINET\Byte/Word Order\MC CMD Intf Order

Reversed

Order is reversed. CMD Header - Par word 1 – Par word 0 - Par word 3 - Par word 2 -

etc...

Not reversed

Order is not reversed. CMD Header - Par word 0 - Par word 1 - Par word 2 - Par

word 3 - etc...

4.1.5 ProfiNet\Monitoring Channels

Defines the source variable by UPID of the four monitoring channels.

Page 19 of 21

NTI AG / LinMot

PROFINET\Monitoring Channels

Channel 1 UPID

Source UPID for Monitoring Channel 1

Channel 2 UPID

Source UPID for Monitoring Channel 2

Channel 3 UPID

Source UPID for Monitoring Channel 3

Channel 4 UPID

Source UPID for Monitoring Channel 4

Page 20 of 21 NTI AG / LinMot

5 Connecting to the PROFINET Network

5.1 Pin Assignment of the Connectors X17-X18

The Ethernet/IP connector is a standard RJ45 female connector with a pin assignment as defined by EIA/TIA

T568B:

X17 - X18

RealTime Ethernet Connector

Pin

Wire color code

Assignment 100 BASE-

TX

1

2

3

4

5

6

7

8

case

WHT/ORG

ORG

WHT/GRN

BLU

WHT/BLU

GRN

WHT/BRN

BRN

-

Rx+

Rx-

Tx+

-

-

Tx-

-

-

-

RJ-45

Use standard patch cables (twisted pair, S/UTP, AWG26) for wiring. This type

of cable is usually referred to as a “Cat5e-Cable”.

X17 is the PROFINET port P1 and X18 the port 2 P2.

This manual suits for next models

8

Table of contents

Other LinMot Recording Equipment manuals