Linolit 550 User manual

GRINDING AND POLISHING

MACHINE 550

GRINDING AND POLISHING

MACHINE 750

Instruction manual

CONTENT

1. Introduction 2

2. Presentation 3

2.1. Responsibility of the owner 3

2.2. Right of the manufacturer 3

2.3. Structure and functions 3

3. Description 4

4. Protection 7

4.1. Start 7

4.2. Emergency stop 8

5. Operation 9

5.1. General safety precautions 9

5.2. Workplace safety 9

5.3. Electrical safety 9

5.4. Personal safety 11

5.5. Personal protective equipment 12

5.6. Adjustment of position of the grip 14

5.7. Connecting the vacuum cleaner 15

5.8. Instructions for grinding. Abrasive tools 15

5.9. Concrete hardness testing 16

5.10. Selection of abrasive tools 17

5.11. Replacement of abrasive tools 18

6. Transport and storage 19

7. Start and stop 20

7.1. Before starting 20

7.2. Start 20

7.3. Stop 20

8. Technical maintenance 21

9. Technical characteristics 22

- 2 -

1. INTRODUCTION

Warning! If the machine is used incorrectly, it can be a

dangerous tool that can cause serious injuries or even death.

Before operating the machine, please read the instructions

carefully and make sure you understand them.

Use personal protective equipment (see chapter

"Personal protective equipment").

Warning! Grinding produces dust and inhalation of

dust may result in injuries. Use the respirator. Always

provide adequate ventilation.

This machine is in accordance with EU regulations. This

product should not be disposed of as household waste. In

ensuring the proper disposal of this product you will help to

prevent potential negative consequences for the environment

and human health, which may be caused by improper

processing of the product.

POLIRTLAK d.o.o.

Štihova ulica 10, 1000 Ljubljana, Slovenija

GRINDING AND POLISHING MACHINE LINOLIT

Weight: 410 kg

Rotating speed: 0-1000 rev/min

Voltage: 400 V

Current: 32 A

Year of production: 2015

IP protection: 54

- 3 -

2. PRESENTATION!

Dear customer, thank you for buying the machine Linolit. We hope

that you will be satisfied with this product. Purchasing any of our

products gives you right to get the right professional help in order to

repair or maintain the machine.

We hope that this manual will be useful. Have the instructions close

by. Following the content (for proper use, service, maintenance, etc.)

you will significantly extend the life of the machine and increase its

second-hand value. If the machine is traded or sold, give the manual

to the new owner.

2.1. RESPONSIBILITY OF THE OWNER: The owner or employer

is responsible for sufficient knowledge of the operator about the

operation and safety measures of the machine. Managers and

operators have to read the instructions and understand the content.

They have to be familiar with:

-safety instructions for working with the machine;

-application and limitations of the machine;

-operating procedures and technical maintenance of the machine.

2.2. RIGHT OF THE MANUFACTURER: After the publication of

this manual our company may include additional information

concerning safety issues. The owner is responsible for safe working

practice. Our company is continuously working on the improvement

of our products and therefore reserves the right to change the form

and the appearance of the machine without the prior notice.

2.3. STRUCTURE AND FUNCTIONS: Linolit products have high

performance characteristics, such as reliability, the use of innovative

technology, advanced technical solutions and environmental

friendliness. Read this manual carefully before using the machine. For

further information, please contact your local dealer or our company.

- 4 -

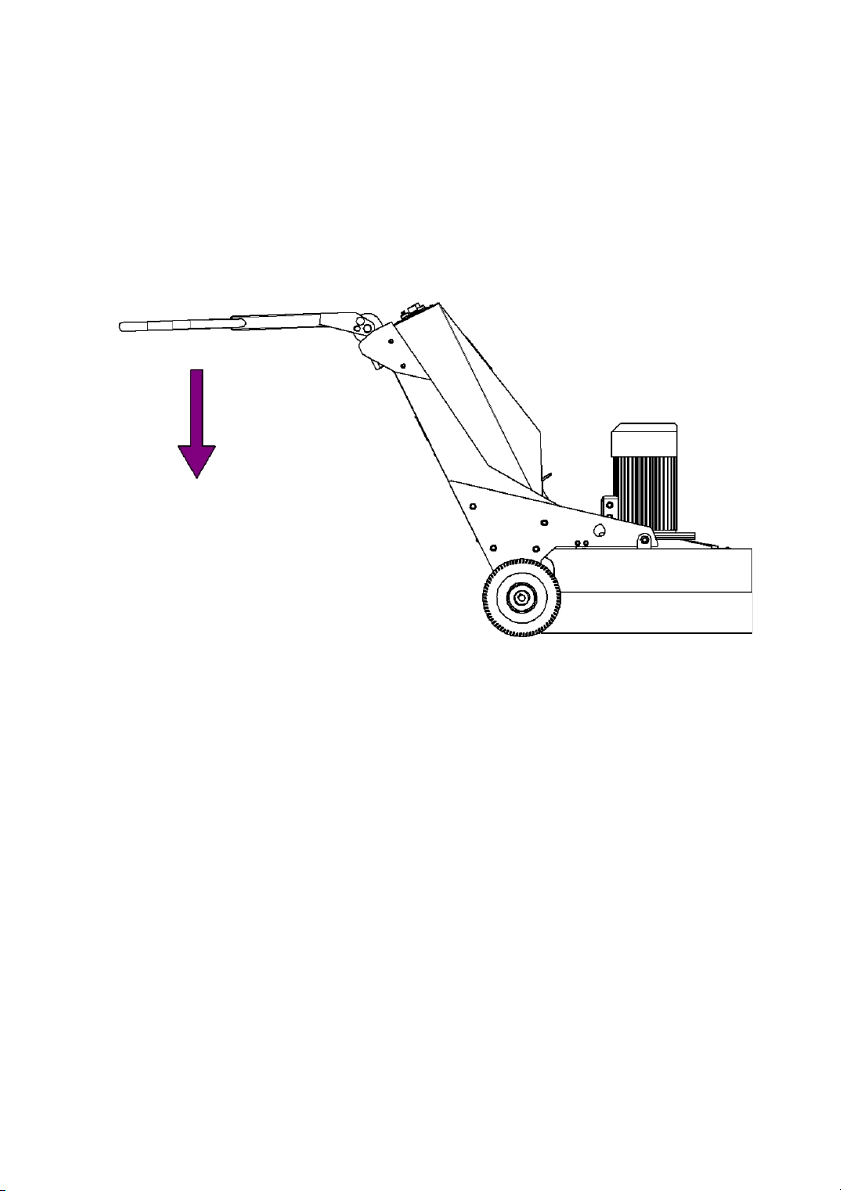

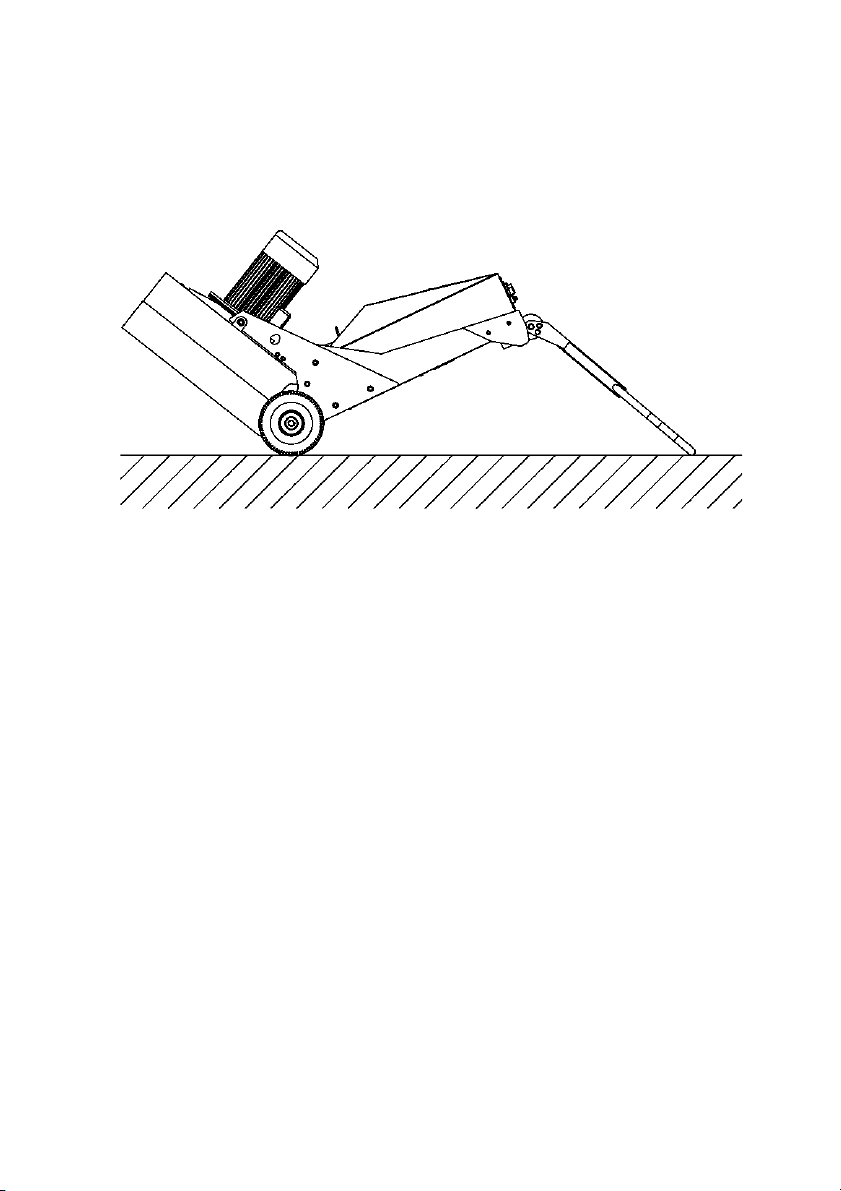

3. DESCRIPTION

LINOLIT-550

1. The machine is suitable for grinding and polishing of concrete

surfaces of different hardness.

2. The machine is reliable and easy to operate.

3. The machine can be disassembled for easy transport.

4. Working surface 550 mm.

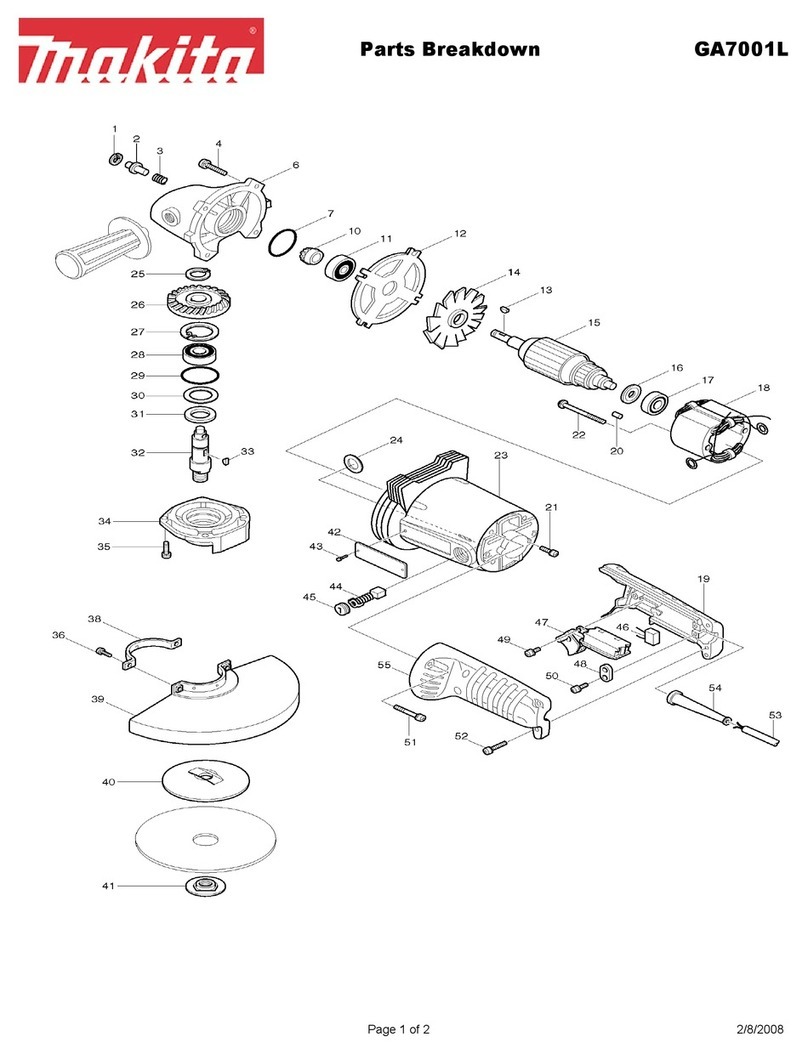

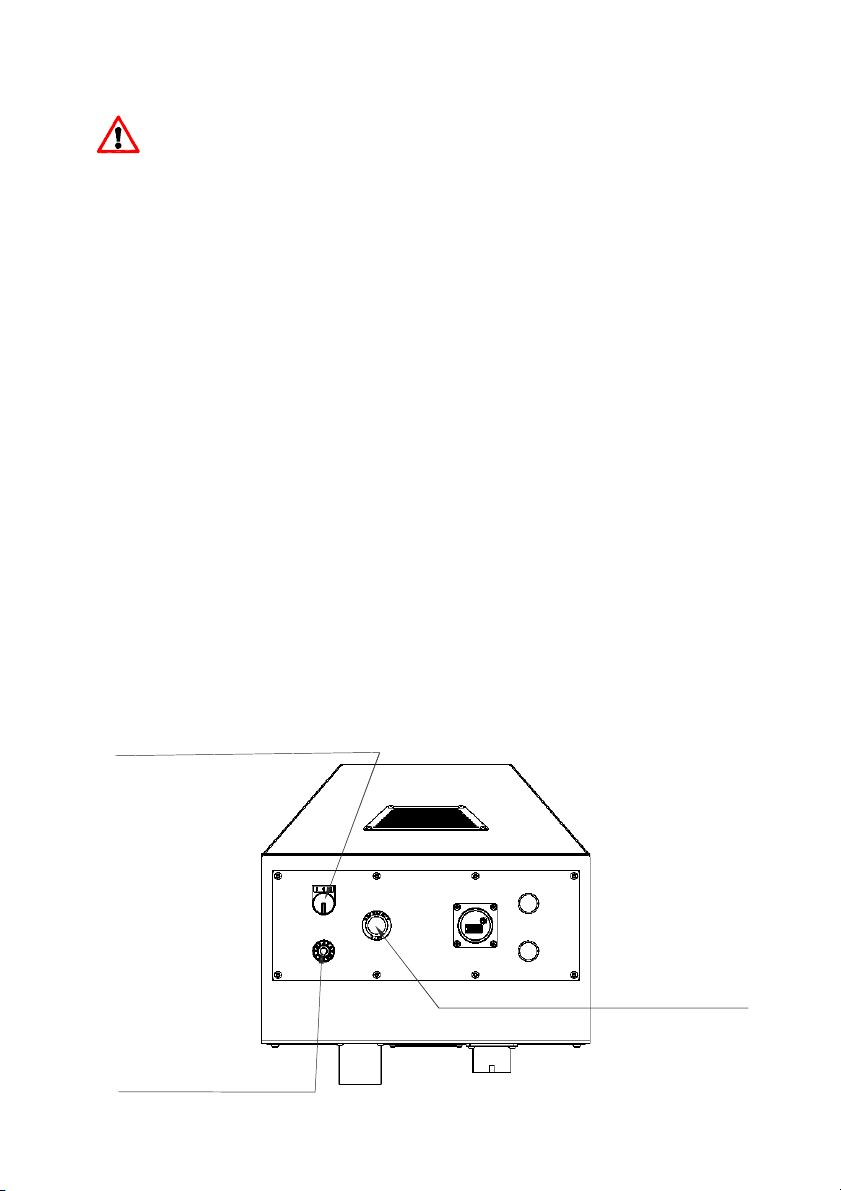

Body Control panel

Grip

Engine

Grinding head

Protective

cover

Removable cover

Frame

Pair of wheels

Control panel

Stop button

Light, indicating the error of frequency

converter operation

Speed regulator

Start button with lighting

Switch

start/stop/reverse

motion

Dust conduit

Img 1

Hour meter

Power supply socket

- 5 -

LINOLIT-750

1. The machine is suitable for grinding and polishing of

concrete surfaces of different hardness.

2. The machine is reliable and easy to operate.

3. The machine can be disassembled for easy transport.

4. Working surface 750 mm.

Control panel

Engine

Frame

Grinding head

Grip

Removable cover

Body

Protective

cover

Pair of wheels

Control panel

Stop button Light, indicating the error of frequency

converter operation

Switch start/stop/reverse motion

Start button with lighting

Speed regulator

Hour meter

Dust conduit

Img 2

Power supply

socket

- 6 -

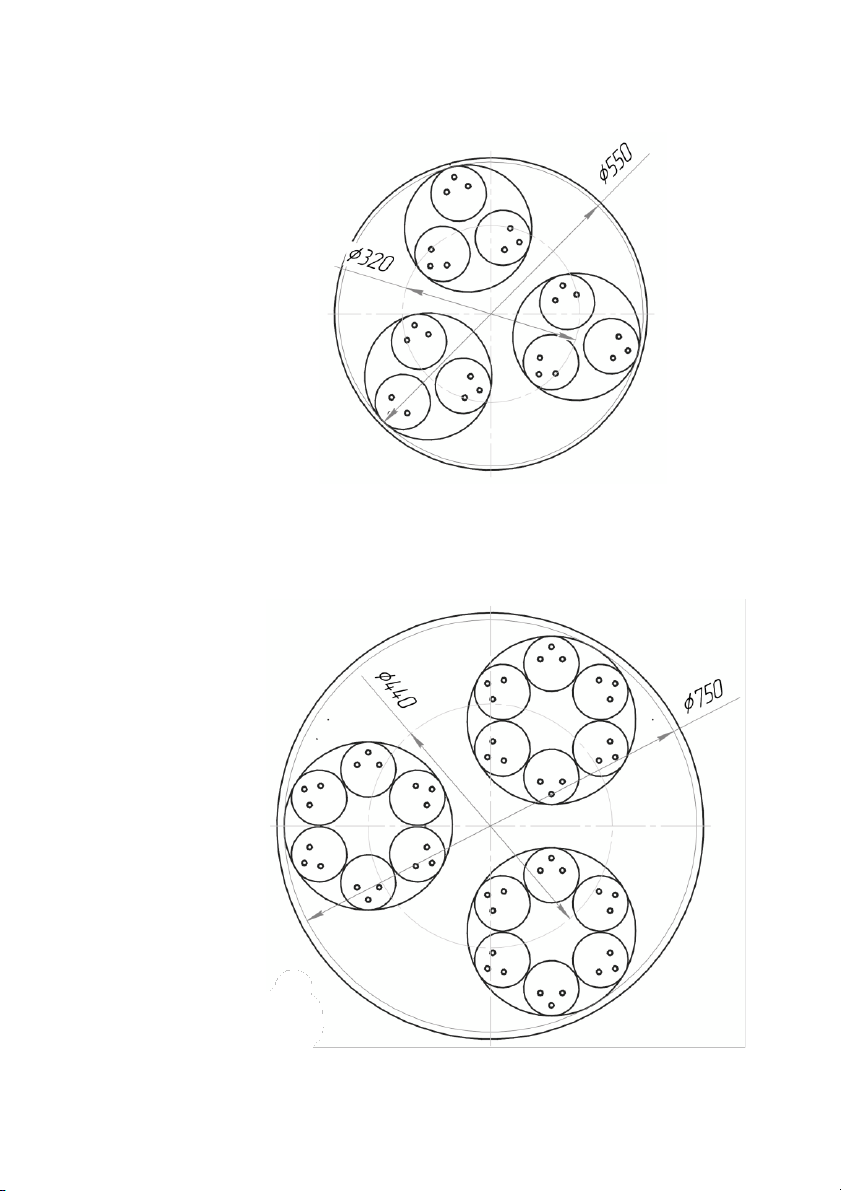

Img 3

Img 4

LINOLIT-550

LINOLIT-750

- 7 -

4. PROTECTION

WARNING! Never use a machine with faulty safety

equipment. Carry out the checks, maintenance and service

instructions described in this manual. In case of irregularities,

immediately contact a specialist to make the reparation.

This section describes basic safety rules for using the machine.

Before operating the machine, please read the instructions carefully

and make sure you understand them.

4.1. Start

Warning! Before connecting the machine to the

electrical supply, make sure that both motor cables are

connected to the distribution sockets on the body of the

machine.

Stop

Switch start/stop/reverse motion (start) is used to start and stop the

machine.

Checking the switch

Press on the STOP button and turn the speed

regulator.

Switch

start/stop/reverse

motion

STOP button

Regulator

- 8 -

Reduce the pressure between the discs and the floor by pulling

down the grip, but without raising the machine from the floor at

startup.

Start the machine by turning the start switch right or left. After

that the machine is running smoothly and increases the engine

speed in 5 sec.

To stop the machine turn the switch in the center position.

4.2. Emergency stop

The emergency stop button is used to immediately stop the

engine operation. The STOP button interrupts the power supply.

Checking the emergency stop:

Reduce the pressure between the discs and the floor by pulling

down the grip. Press on the STOP button. Make sure the

engine is stopped.

Release the STOP button (by turning it clockwise).

- 9 -

5. OPERATION

5.1. GENERAL SAFETY PRECAUTIONS

WARNING! This section describes basic safety rules for using the

machine. This information is never a substitute for professional skills and

experience. If you get into the situation where you feel unsafe, stop and seek

expert advice. Contact your machine dealer, service agent or an experienced

machine user. Do not attempt any task that you feel unsure of.

Before operating the machine, please read the instructions carefully and

make sure you understand them.

Save the instructions and safety precautions for later use.

5.2. WORKPLACE SAFETY

The workplace should be kept clean and well lighted. In dark and cluttered

areas the risk for accidents is increased. Do not operate the machine in areas

at risk of fire or explosions.

5.3. ELECTRICAL SAFETY

WARNING! When using electrical devices there is a risk of electric shock.

Avoid unfavorable weather conditions and body contact with lightning

conductors and metal objects. Follow the instructions for use in order to

avoid injuries.

- Do not connect the machine to the electrical supply if the socket or cable

is damaged.

- Check that the mains voltage corresponds to the voltage on the rating

plate of the machine.

- Inspection and maintenance must be performed when the engine is

powered down and the plug is removed from the socket.

- Always turn the machine off before unplugging it from the electrical

outlet.

- Do not move the machine while disconnecting it. Disconnect the plug by

pulling the plug, not the cable.

- Do not operate the machine with a damaged power cord or plug. If the

power cord or the plug is damaged, contact your service representative to

change a new one.

- Do not operate the machine where water can reach the equipment. It

can damage the equipment or injure the operator.

- 10 -

- Always disconnect the power cord when installing or removing the

engine cord from the distribution board.

Instructions for grounding:

WARNING! A poor connection may result in risk of electric shock.

In case of doubt about the reliability of the grounding of the machine,

contact a qualified electrician.

- Do not modify the plug. If the plug does not fit into the socket, contact a

qualified electrician to replace the socket.

- Ensure compliance with local laws and regulations.

- In case of doubt concerning the instructions about grounding,

contact a qualified electrician.

- The machine is provided with a grounded cable and plug and must

always be connected to a grounded socket. This reduces the risk of electric

shock in the event of failure.

- Using the machine, do not use adapters.

Cables and extension cords

- The voltage of the extension cord must agree with the voltage

specified on the nameplate of the machine.

- Use grounded extension cords.

- When operating a power tool outdoors, use an extension cord suitable

for outdoor use. Use of a cord suitable for outdoor use reduces the risk of

electric shock.

- Safe extension cord must be protected from moisture and should not

touch the ground.

- Keep the extension cord away from heat, oily substances, sharp and

moving objects. Damaged or entangled cords increase the risk of electric

shock.

- Make sure that the cables are not damaged and that they are in good

condition. Never use the machine if the cable is damaged, rather put it into

an authorized service workshop for repair.

- Do not use folded extension cord in order to avoid overheating.

- When starting to operate the machine, make sure cord is behind you to

prevent damaging it.

- Use only certified extension cords with sufficient reach.

5.4. PERSONAL SAFETY

WARNING! Prolonged exposure to vibration has negative

effects on the blood vessels and can cause disorders of the

nervous system which is a serious condition for people with

impaired circulation. Contact your doctor if you experience

symptoms of overexposure to vibration. These symptoms

include loss of feeling, tingling, pricking, pain, loss of strength,

changes in skin color or condition. These symptoms normally

appear in the fingers, hands or wrists. These symptoms may be

increased in cold temperatures.

- Use personal protective equipment (see chapter

"Personal protective equipment").

- Never use the machine if you are tired, if you have drunk

alcohol, or if you are taking medication that could affect your

vision, your judgment or your co-ordination.

- Never allow anyone else to use the machine without first

ensuring that they have understood the contents of the

operator's manual.

- Your employer must make sure you have the information you

need or required training to work with the machine safely and

effectively.

- The presence of unauthorized people can decrease attention,

necessary for safe work with the machine. Be extremely

careful. Focus on the operation of the machine. Never allow

children to use or be near the machine.

- Follow safety rules and do not wear loose clothing, long hair,

or jewelry that can get into rotating parts during the machine

operation.

- Do not squeeze and harm your fingers with the

machine open moving parts. Keep distance!

- Do not leave machine running unattended.

- Next to you, there needs to be another person that will help

you in case of an accident.

- Always be in a safe and stable position.

- 11 -

5.5. PERSONAL PROTECTIVE EQUIPMENT

WARNING! You must use approved personal protective

equipment whenever you use the machine. Personal protective

equipment cannot eliminate the risk of injury but it will reduce the

degree of injury if an accident does happen. Ask your dealer for help

in choosing the right equipment:

Hearing protection

Respirator

Heavy-duty firm grip gloves

Protective glasses or visor

Tight-fitting, heavy-duty and comfortable

clothing that permits full freedom of

movement

Boots with toe-caps and non-slip sole

Before using the machine, read the instructions

manual and make sure you understand the content.

Always have a first aid kit nearby.

- 12 -

USE AND MAINTENANCE

- Never use the machine for other purposes than what it has been

constructed for.

- Make sure that all parts are in good operating condition and

that connections are properly connected.

- Never use a machine that is faulty. Carry out the checks,

maintenance and service instructions described in this manual.

Some maintenance and service measures must be carried out by

trained and qualified specialists (see chapter "Technical

maintenance").

- Do not modify safety equipment. Check it regularly to be sure it

works properly. The machine must not be used with defective or

damaged protective equipment.

- Never use a machine that has been modified in any way from

its original specification.

- Use only original spare parts. For more information, contact the

dealer.

- Run the machine only when the grinding head is on the ground,

except in case of checking the equipment as described in this

manual.

- Do not run the machine if the edge with the protective cover is

not fixed. For security purposes the connection between the

machine and the floor has to be rigid, especially for dry

grinding.

- When grinding, connect the machine to a vacuum cleaner to

remove dust.

- When replacing removable discs, disconnect the machine from the

mains; push the STOP button and remove the plug from the supply

socket.

- After every operation abrasive tools must be removed.

- 13 -

- Make sure that the protective cover is clean, not damaged

and fits tightly to the floor.

If the protective cover is damaged, replace it with a new one.

- When you shut the engine off, the bearing disc stops spinning after a

short time. Continue with grinding until the grinding

head stops spinning completely. Before lifting the machine, make sure

the bearing disc stopped spinning.

- When grinding adhesive surfaces, such as asphalt, paints etc., after

completed work slightly lift the front part of the machine to prevent

sticking to the floor because of the heated surfaces. Before lifting the

machine, make sure the bearing disc stopped spinning.

- The temperature of removable discs after the operation can be very

high. Before removing them wait until the machine is cool. Use

protective gloves.

- Do not use the machine on the sand, stairs, walls, roof, and

ceramic tiles.

- Do not use the machine, if it is exposed to precipitations.

- When using the machine, be careful not to hit the power cord.

- Make sure no one is present at a distance of one meter in front of

the machine.

- In case of failure contact the company Polirtlak d.o.o., Štihova ulica

10, 1000 Ljubljana, Slovenia) to repair the machine.

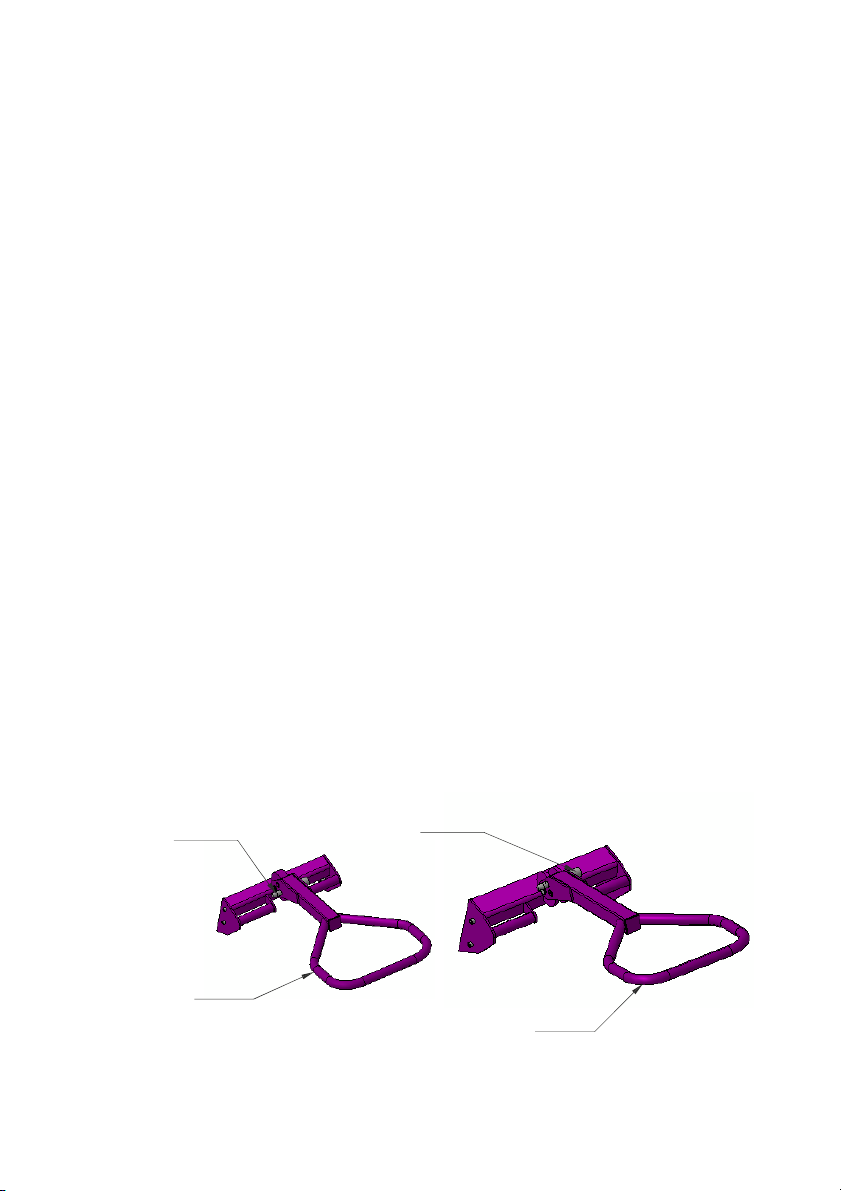

5.6. ADJUSTMENT OF POSITION OF THE GRIP

The position of the grip is steplessly adjustable. In order to

adjust the position of the grip, loosen the screws on the lock.

Set the grip to the desired position and tighten the screws.

LINOLIT-550 LINOLIT-750

Lock

Lock

Grip

Grip

- 14 -

5.7. CONNECTING THE VACUUM CLEANER

For complete dust collection use vacuum cleaners Linolit. Connect

the vacuum cleaner to the dust conduit (see img 1 and img 2), use

the hose of diameter of 60 mm.

Make sure that the filters in the vacuum cleaner are clean and not

damaged. When working pay attention to the formation of the dust.

5.8. INSTRUCTIONS FOR GRINDING. ABRASIVE TOOLS

Usually abrasive segment consists of two

components:

1. Abrasive material (usually referred as abrasive particles). The

size of abrasive particles affects the size of scratches (deep and

shallow) that remain after grinding.

2. Bond (metal or resin). Using metal as a bond, the final product is

called segment with metal bond or sintered abrasive segment. Using

resin as a bond,the final product is called abrasive tools with resin

bond or polishing disc. Hardness of the bond affects the wear rate

of the abrasive material.

1. Changing the abrasive particles to smaller parts/grains affects

the functioning of abrasive tools as follows:

-less deep scratches

-increased service life of abrasive tools

An opposite effect is achieved, if changing the abrasive particles

to bigger parts/grains.

2. Stiffening bond:

-less deep scratches;

-increased service life of abrasive tools;

-reduced productivity.

An opposite effect is achieved, if mitigating the stiffness of metal

or polymer bond.

Increasing the quantity of abrasive pads under the machine

result in:

-reduced pressure on the individual abrasive pad;

-lower degree of wear;

-reduced load on the machine and lower power

consumption;

-less deep scratches (particularly on the soft floor);

An opposite effect is achieved, if reducing the quantity of tools

under the machine.

Abrasive pads are designed to meet the high performance surface

treatment.

-15-

The lifetime of abrasive tools can be affected by following factors:

-pressure;

-stiffness of the bond;

-size of abrasive grinding grain;

-number of segments under the machine;

-additional abrasive material on the floor (e.g. sand, silicon

carbide) increases wear.

Usually if the abrasive disc wears out faster, the productivity is

higher. Changes in the factors above may affect:

-the distribution of scratches;

-the consumption of electrical current;

-the surface plane (see chapter "CONCRETE

HARDNESS TESTING");

-the ease of operation.

5.9. CONCRETE HARDNESS TESTING

Different types of concrete are characterized by their compressive

strength; different countries use various indicators to evaluate the

compressive strength (e.g. pounds/square inches and MPA).

Generally, if the compressive strength is higher, the concrete is

harder, and it is harder to grind it.

In addition to compressive strength, there are other factors that

affect the hardness of the floor and therefore determine the

selection of abrasive pad. Most often when talking about grinding

and polishing, this refers to the upper layer (5 mm). Concrete

surface treatment and the condition of concrete surface have much

bigger impact on the selection of abrasive segment than the

compressive strength.

Surface characteristics, important for the selection of abrasive

pads.

Usually, if the concrete surface is very smooth (e.g. in the case of

intense polishing/smoothing of the floor), the concrete characteristic

will be high compressive strength, and to process it you will need to

use the segment with a soft bond.

In the opposite case, if the concrete surface is very rough/coarse

(e.g. under the influence of rain, bumps, chopping etc.), the

concrete characteristic will be low compressive strength, and to

process it you will need to use the segment with a hard bond.

-16-

Presence of surface coating/contamination (e.g., epoxy coatings,

ceramic tile adhesives, leveling compounds/smoothers) often have

much bigger impact on the selection of abrasive segment than the

compressive strength.

When grinding concrete tiles for the first time, if you are not sure

about the hardness of concrete, start processing by using abrasive

tools with harder bond. This will ensure minimal wear of abrasive

segments. Even if the hard abrasive segment is not appropriate, all

the damage is in a loss of a small amount of time, without the wear

of abrasive tools.

In the opposite case (e.g. using first abrasive tools with soft bond),

if the concrete is soft and has a rough or coarse surface, there is

high probability of fast wear of a significant number of abrasive

tools.

5.10. SELECTION OF ABRASIVE TOOLS

Method of placing abrasive segments on the machine is

very important; it affects the machine operation,

productivity and final quality of concrete surface. Our

company recommends the following method of placing:

LINOLIT-550

LINOLIT-750

-17-

5.11. REPLACEMENT OF ABRASIVE TOOLS

Turn off the machine, and unplug the power cord of the

machine from the power supply. Keep a pair of gloves handy,

because the pads can be very hot.

Place the machine in a horizontal position.

Put on the gloves. Remove the abrasive pads. Put the new

abrasive segments on the bearing disc. After having installed

new abrasive discs, repeat the procedure in reverse order and

put the machine back on the ground.

When putting the device into horizontal position in order to

replace diamond pads must be present at least two workers.

-18-

6. TRANSPORT AND STORAGE

1. Firmly attach the equipment during transportation in

order to avoid damages and accidents.

2. If possible, cover the machine during transportation in

order to limit the impact of natural disasters, especially rain

and snow.

3. Store the equipment in a locked room, inaccessible to

children and unauthorized persons.

4. If the machine is not in use, store it in a dry place.

TRANSPORT

The machine can be disassembled and reassembled to take

less space when transporting.

- Disconnect the motor cable from the distribution

board;

- Remove the screws;

- Disconnect the grinding head from the support frame.

-19-

This manual suits for next models

1

Table of contents

Popular Grinder manuals by other brands

Cornwell Tools

Cornwell Tools CAT-400HDG operating instructions

Trade Professional

Trade Professional MCOP1567 user manual

Silverline

Silverline 268953 manual

Makita

Makita DGA404 instruction manual

Scheppach

Scheppach SM150LB Original instruction manual

Clarke

Clarke CAT83 Operating & maintenance instructions